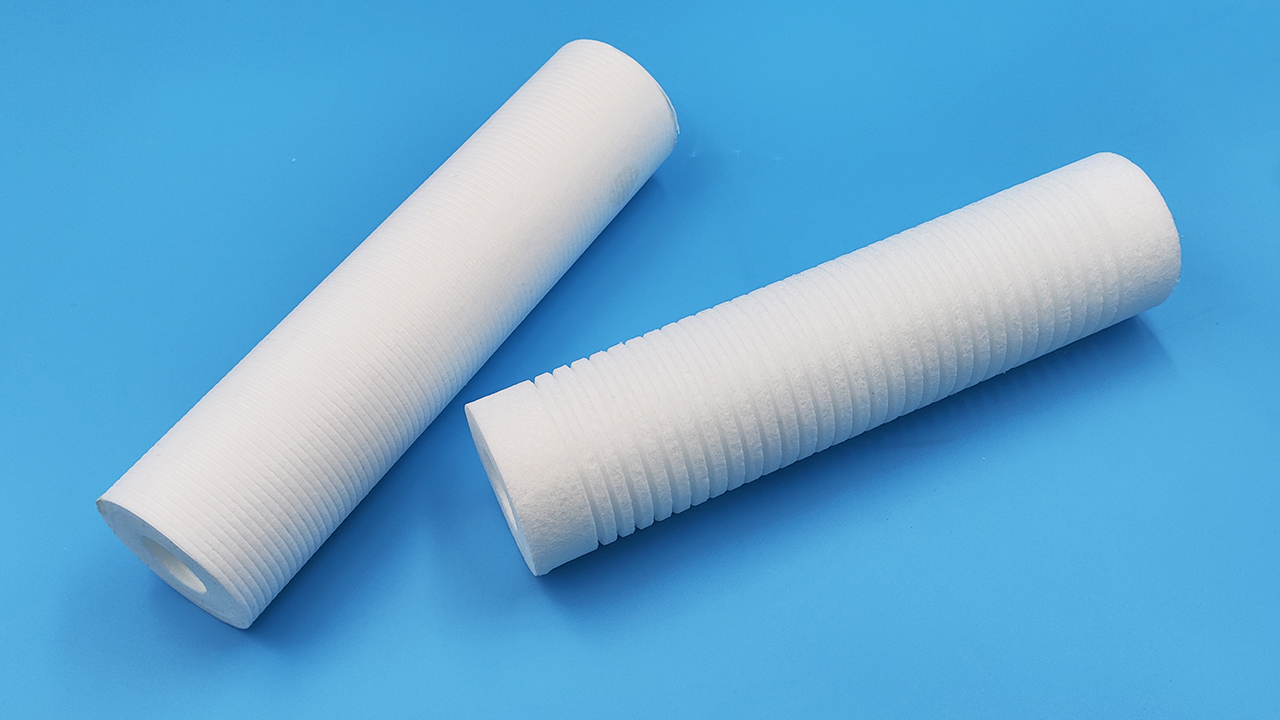

PP Melt Blown Cartridge Filter Designed for Depth Filtration Needs

# PP Melt Blown Cartridge Filter Designed for Depth Filtration Needs

Understanding the Importance of Depth Filtration

Depth filtration is a crucial process in many industries, including water treatment, pharmaceuticals, and food processing. The PP Melt Blown Cartridge Filter is specifically designed to address the unique challenges posed by these sectors. With its superior filtration capabilities, this filter ensures that contaminants are effectively removed, providing cleaner and safer end products.

The melt-blown technology used in manufacturing these cartridges allows for an intricate fiber structure that captures particles throughout the entire depth of the filter. This characteristic not only enhances the filter’s lifespan but also improves its efficiency in holding back dirt and impurities, making it a reliable choice for depth filtration needs.

Benefits of Using PP Melt Blown Cartridge Filters

One of the primary advantages of PP Melt Blown Cartridge Filters is their versatility. They are suitable for various applications, from industrial to residential usage. These filters can handle a range of flow rates and particle sizes, ensuring optimal performance across different systems and settings.

Moreover, these cartridge filters are manufactured from polypropylene, which is known for its chemical resistance and durability. This means that they can withstand harsh conditions without compromising on performance, offering a cost-effective solution for long-term use.

Applications of PP Melt Blown Cartridge Filters

PP Melt Blown Cartridge Filters find extensive applications in numerous industries. In water treatment facilities, they play a vital role in pre-filtration processes, ensuring that larger particles are captured before water undergoes further purification steps.

In the pharmaceutical industry, maintaining product purity is essential. These filters help eliminate potential contaminants, thus safeguarding the integrity of medicines and other health-related products. Additionally, in the food processing sector, the filters contribute to meeting stringent safety regulations by ensuring that all products are free from harmful impurities.

How to Choose the Right PP Melt Blown Cartridge Filter

Selecting the right PP Melt Blown Cartridge Filter involves considering several factors, including the specific application, flow rate requirements, and the type of contaminants present. It’s essential to assess your filtration needs carefully to ensure you choose a filter that meets your operational standards.

Furthermore, understanding the micron rating of the filter is crucial. Different applications may require different levels of filtration, and the micron rating helps determine the filter’s capacity to remove specific particle sizes effectively. Consulting with filtration experts can provide valuable insights into making the best choice for your needs.

Maintaining Your PP Melt Blown Cartridge Filter

Proper maintenance of your PP Melt Blown Cartridge Filter is key to ensuring its longevity and effectiveness. Regularly checking the filter for signs of clogging or wear can help prevent unexpected downtime and maintain optimal filtration performance.

Replacement schedules should be based on the manufacturer’s recommendations and the specific usage conditions. By staying proactive about maintenance and replacements, you can maximize the efficiency of your filtration system and ensure consistent quality in your processes.