Best Practices for Properly Closing a Rosin Press Bag for Cleaner Extractions

Proper Bag Sealing Techniques

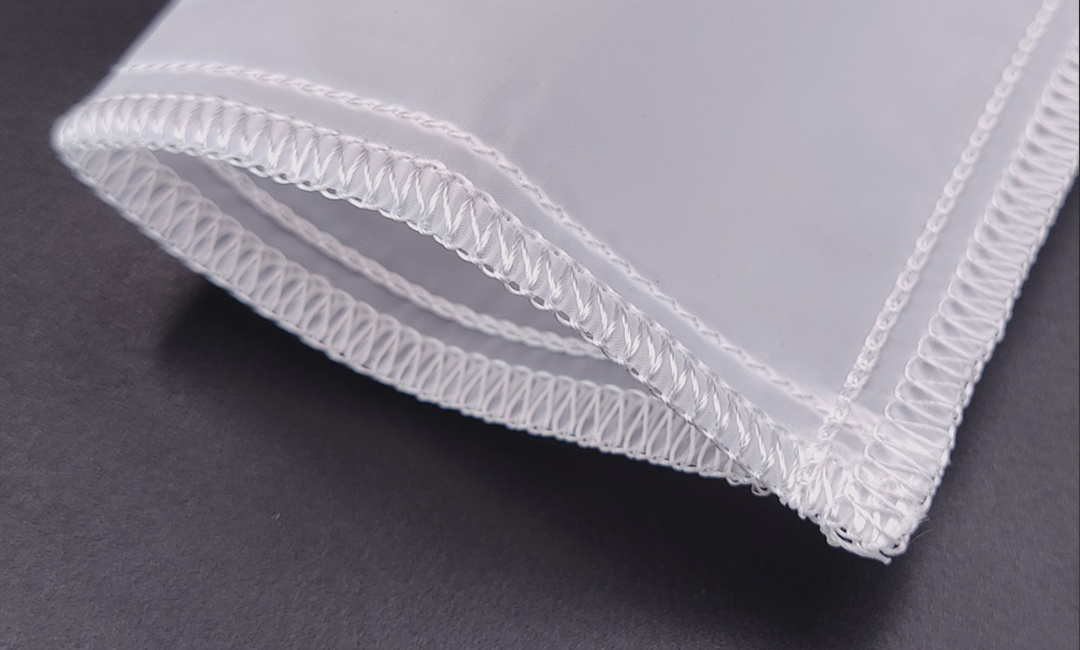

When it comes to achieving cleaner extractions in the rosin pressing process, the importance of properly sealing rosin press bags cannot be overstated. The sealing technique employed not only affects the quality of the final product but also influences the efficiency of the extraction process. To begin with, it is essential to select the right type of rosin press bag, as the material and size can significantly impact the outcome. High-quality, food-grade nylon or polyester bags are recommended, as they are designed to withstand the heat and pressure involved in the extraction process while allowing for optimal filtration.

Once the appropriate bag is chosen, the next step involves preparing the material for extraction. It is crucial to ensure that the plant material is evenly distributed within the bag. This uniformity allows for consistent pressure during the pressing process, which is vital for achieving a high-quality yield. After filling the bag, it is important to leave enough space at the top to facilitate proper sealing. A common mistake is overfilling the bag, which can lead to leaks and contamination during extraction.

To seal the bag effectively, one must employ a technique that minimizes the risk of any material escaping during the pressing process. One of the best practices is to fold the top of the bag over itself before sealing. This fold creates a barrier that helps contain the material and prevents it from being forced out during extraction. Additionally, using a heat sealer can provide a more secure closure compared to traditional methods such as tying or using clips. Heat sealing not only ensures a tight seal but also reduces the likelihood of any contaminants entering the bag.

Moreover, it is advisable to check the integrity of the seal before proceeding with the extraction. A simple visual inspection can help identify any weak points or potential leaks. If any issues are detected, it is prudent to reseal the bag to avoid compromising the extraction process. Furthermore, using a double-bagging technique can enhance the security of the contents. By placing the filled and sealed bag inside another bag, the risk of leaks is significantly reduced, ensuring that the extraction remains clean and uncontaminated.

In addition to these sealing techniques, it is also important to consider the temperature and pressure settings of the rosin press. The ideal temperature range for pressing rosin typically falls between 180°F and 220°F, depending on the type of material being used. Maintaining the correct temperature is crucial, as excessive heat can degrade the quality of the extract, while insufficient heat may result in lower yields. Similarly, the pressure applied during the extraction process should be carefully monitored. Too much pressure can cause the bag to burst, while too little may not extract the desired amount of resin.

Finally, after the extraction is complete, it is essential to handle the sealed bag with care. Allowing the bag to cool before opening can help prevent any residual heat from affecting the quality of the extract. Once cooled, the bag can be opened, and the extracted rosin can be collected. By following these best practices for properly closing a rosin press bag, one can ensure cleaner extractions and a higher quality final product. Ultimately, attention to detail in the sealing process not only enhances the efficiency of the extraction but also contributes to the overall success of the rosin pressing endeavor.

Choosing the Right Rosin Press Bag

When it comes to extracting rosin from cannabis or hemp, using a rosin press bag is essential for achieving clean and high-quality results. These bags are designed to hold the plant material while allowing the rosin to be extracted through the mesh. However, properly closing the rosin press bag is crucial to prevent any contaminants from getting into the final product. In this article, we will discuss the best practices for closing a rosin press bag to ensure cleaner extractions.

First and foremost, it is important to choose the right rosin press bag for your extraction needs. There are different sizes and mesh sizes available, so be sure to select a bag that is appropriate for the amount and type of plant material you will be using. A finer mesh size will result in a cleaner extraction, while a larger mesh size may allow more plant material to pass through, affecting the quality of the rosin.

Once you have selected the appropriate rosin press bag, it is time to properly close it before placing it in the rosin press. One common method is to fold over the top of the bag and then use a heat sealer to seal it shut. This creates a tight seal that prevents any plant material from escaping during the extraction process. Alternatively, some users prefer to use a twist tie or rubber band to secure the top of the bag. Whichever method you choose, make sure that the bag is securely closed to avoid any leaks or spills.

Another important consideration when closing a rosin press bag is to ensure that there are no gaps or openings where plant material could escape. Inspect the bag carefully before sealing it to make sure that there are no tears or holes that could compromise the extraction process. If you do find any defects, it is best to discard the bag and use a new one to prevent any contamination.

In addition to properly closing the rosin press bag, it is also important to pack the plant material evenly and tightly inside the bag. This will help to ensure that the rosin is extracted evenly and efficiently, resulting in a higher yield and better quality product. Avoid overfilling the bag, as this can cause the material to spill out during the extraction process. Instead, fill the bag to about three-quarters full to allow room for the plant material to expand as it is pressed.

Finally, when closing a rosin press bag, it is important to label it with the date and strain of the plant material being used. This will help you keep track of your extractions and ensure that you are using fresh and high-quality material for each batch. Additionally, labeling the bags can help you identify any issues or inconsistencies in your extraction process, allowing you to make adjustments as needed.

In conclusion, properly closing a rosin press bag is essential for achieving clean and high-quality extractions. By choosing the right bag, sealing it securely, and packing the plant material evenly, you can ensure that your rosin is free of contaminants and of the highest quality. Remember to inspect the bag for any defects before sealing it, and label it with the necessary information to track your extractions. By following these best practices, you can improve the efficiency and effectiveness of your rosin extraction process.

Importance of Bag Size and Material

When it comes to achieving cleaner extractions in the rosin pressing process, the importance of bag size and material cannot be overstated. Selecting the right bag is a critical step that directly influences the quality of the final product. The size of the bag plays a pivotal role in determining how well the plant material is contained during the pressing process. A bag that is too small may lead to overpacking, which can result in uneven pressure distribution and ultimately compromise the extraction quality. Conversely, a bag that is excessively large may allow for unnecessary movement of the material, leading to a less efficient extraction and potential contamination from outside elements.

In addition to size, the material of the bag is equally significant. Rosin press bags are typically made from nylon or other synthetic fibers that are designed to withstand high temperatures and pressures. The choice of material affects not only the durability of the bag but also its ability to filter out unwanted plant matter. High-quality bags with a fine micron rating are essential for ensuring that only the desired oils and terpenes are extracted, while larger micron bags may allow for more plant material to pass through, resulting in a less pure product. Therefore, it is crucial to select bags that are specifically designed for rosin extraction, as they are engineered to provide optimal filtration and durability.

Moreover, the thickness of the bag material can also impact the extraction process. Thicker bags may offer better resistance to tearing and puncturing, which is particularly important when dealing with high-pressure applications. However, it is essential to strike a balance, as overly thick bags may hinder the flow of oils during extraction, leading to suboptimal yields. Thus, understanding the interplay between bag thickness and extraction efficiency is vital for achieving the best results.

Transitioning from the technical aspects of bag size and material, it is also important to consider the specific type of plant material being used. Different strains and types of cannabis may require different bag sizes and materials to optimize extraction. For instance, denser, more resinous strains may benefit from smaller bags that can contain the material more effectively, while lighter strains may perform better in larger bags that allow for more airflow. This nuanced understanding of how bag characteristics interact with the properties of the plant material can significantly enhance the quality of the extraction.

In addition to these considerations, proper sealing techniques are essential for ensuring that the bag remains intact during the pressing process. A well-sealed bag prevents any leakage of oils and plant material, which can contaminate the final product. Utilizing heat-sealing methods or high-quality ties can help maintain the integrity of the bag throughout the extraction process. Furthermore, ensuring that the bag is filled evenly and not overstuffed will contribute to a more uniform extraction, allowing for a cleaner and more potent end product.

In conclusion, the importance of bag size and material in the rosin pressing process cannot be overlooked. By carefully selecting the appropriate bag size and material, as well as employing proper sealing techniques, one can significantly enhance the quality of the extraction. This attention to detail not only leads to cleaner extractions but also maximizes the yield and potency of the final product, ultimately contributing to a more successful rosin pressing experience.

Tips for Avoiding Contamination During Extraction

Rosin extraction has become increasingly popular in the cannabis industry due to its simplicity and effectiveness in producing high-quality concentrates. One crucial aspect of the rosin extraction process is properly closing the rosin press bag to prevent contamination and ensure a clean extraction. In this article, we will discuss some best practices for closing a rosin press bag to achieve cleaner extractions.

First and foremost, it is essential to use high-quality rosin press bags made from food-grade nylon or polyester. These bags are designed to withstand high temperatures and pressure during the extraction process, ensuring that no harmful chemicals or residues leach into the final product. Additionally, using the correct size of rosin press bag for your material is crucial to prevent blowouts and ensure an even distribution of pressure during extraction.

When closing a rosin press bag, it is important to fold the edges of the bag over to create a tight seal. This will prevent any material from escaping during the extraction process and help maintain a clean working environment. Some users prefer to use a heat sealer to seal the edges of the bag, while others opt for a simple fold-and-clip method. Whichever method you choose, make sure that the bag is securely closed to avoid any leaks or contamination.

Another best practice for closing a rosin press bag is to pre-press the material before placing it in the bag. This will help compact the material and create a more even surface for extraction, resulting in a higher yield and cleaner product. Additionally, pre-pressing the material can help prevent blowouts and ensure that the bag is properly sealed before starting the extraction process.

It is also important to consider the temperature and pressure settings of your rosin press when closing the bag. Different strains and materials may require different settings to achieve optimal extraction results. Make sure to follow the manufacturer’s guidelines and experiment with different settings to find the best combination for your specific material.

Furthermore, it is crucial to clean and sanitize your rosin press bags regularly to prevent contamination and maintain the quality of your extractions. After each use, remove any leftover material from the bag and wash it with warm water and mild detergent. Allow the bag to dry completely before storing it in a clean, dry place. Regularly inspect the bags for any signs of wear or damage, and replace them as needed to ensure consistent extraction results.

In conclusion, properly closing a rosin press bag is essential for achieving cleaner extractions and maintaining the quality of your concentrates. By using high-quality bags, sealing them securely, pre-pressing the material, and following the manufacturer’s guidelines for temperature and pressure settings, you can ensure a successful extraction process. Additionally, regular cleaning and maintenance of your rosin press bags will help prevent contamination and ensure the longevity of your equipment. By following these best practices, you can enjoy high-quality rosin extractions that are free from impurities and contaminants.