1 Micron Spun Filter for Ultra-Fine Particle Removal

# 1 Micron Spun Filter for Ultra-Fine Particle Removal

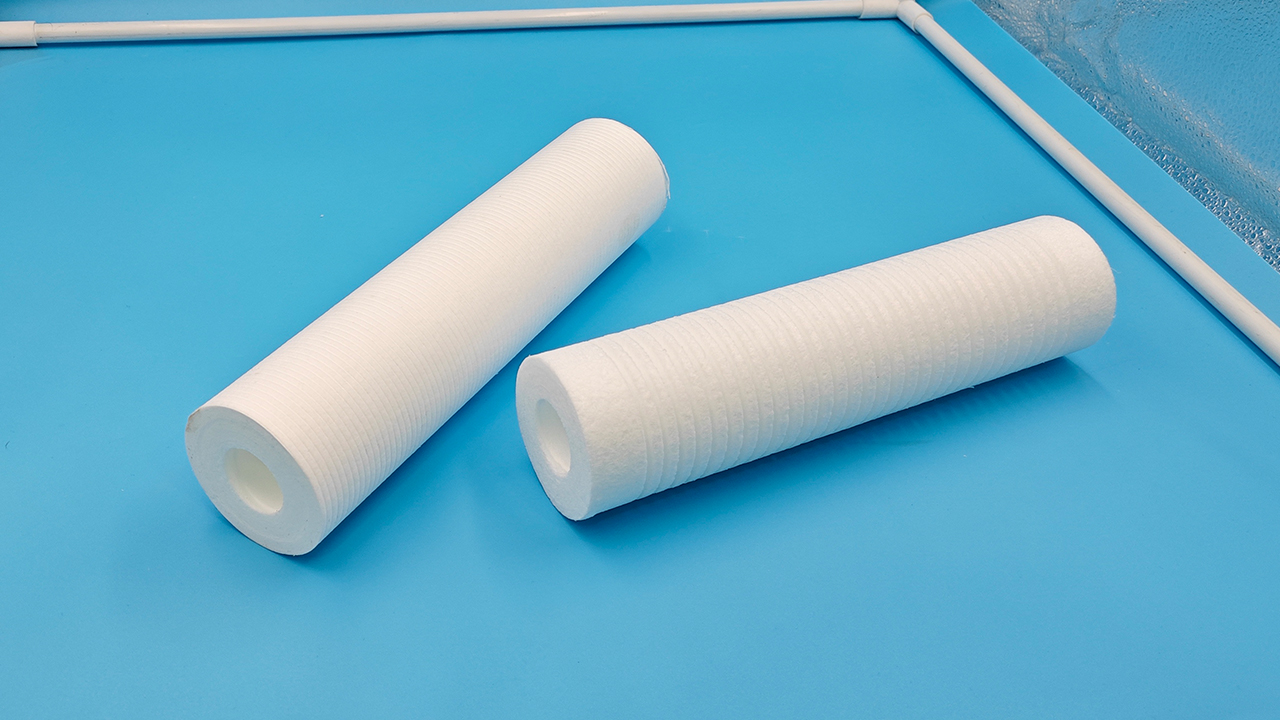

What is a 1 Micron Spun Filter?

A 1 Micron Spun Filter is a highly efficient filtration solution designed to remove ultra-fine particles from liquids. These filters are specifically engineered to capture contaminants that are as small as one micron in size, making them essential for various applications, including water treatment, industrial processes, and food and beverage production.

The spun filter’s construction allows for a high dirt-holding capacity, ensuring longer service life and reduced maintenance costs. By utilizing advanced manufacturing techniques, these filters provide consistent performance and reliability, making them a preferred choice among professionals seeking superior filtration solutions.

Benefits of Using a 1 Micron Spun Filter

One of the primary benefits of using a 1 Micron Spun Filter is its ability to enhance the quality of the final product. By effectively removing particles, such as sediment, rust, and other impurities, these filters ensure that the liquid remains clear and safe for consumption or use in sensitive processes.

In addition to improving product quality, these filters also contribute to operational efficiency. By reducing the load on downstream equipment, such as pumps and membranes, a 1 Micron Spun Filter minimizes wear and tear, leading to lower energy costs and extended equipment lifespan.

Applications of 1 Micron Spun Filters

The versatility of 1 Micron Spun Filters makes them suitable for a wide range of applications. In the water treatment industry, they are commonly used to pre-filter water before it undergoes further purification processes. This ensures that larger particles do not interfere with the effectiveness of reverse osmosis and other treatment methods.

Additionally, in the food and beverage sector, these filters play a crucial role in maintaining the purity of products such as juices, wines, and dairy. By eliminating unwanted particles, they help ensure compliance with health and safety standards, thereby protecting both consumers and brands alike.

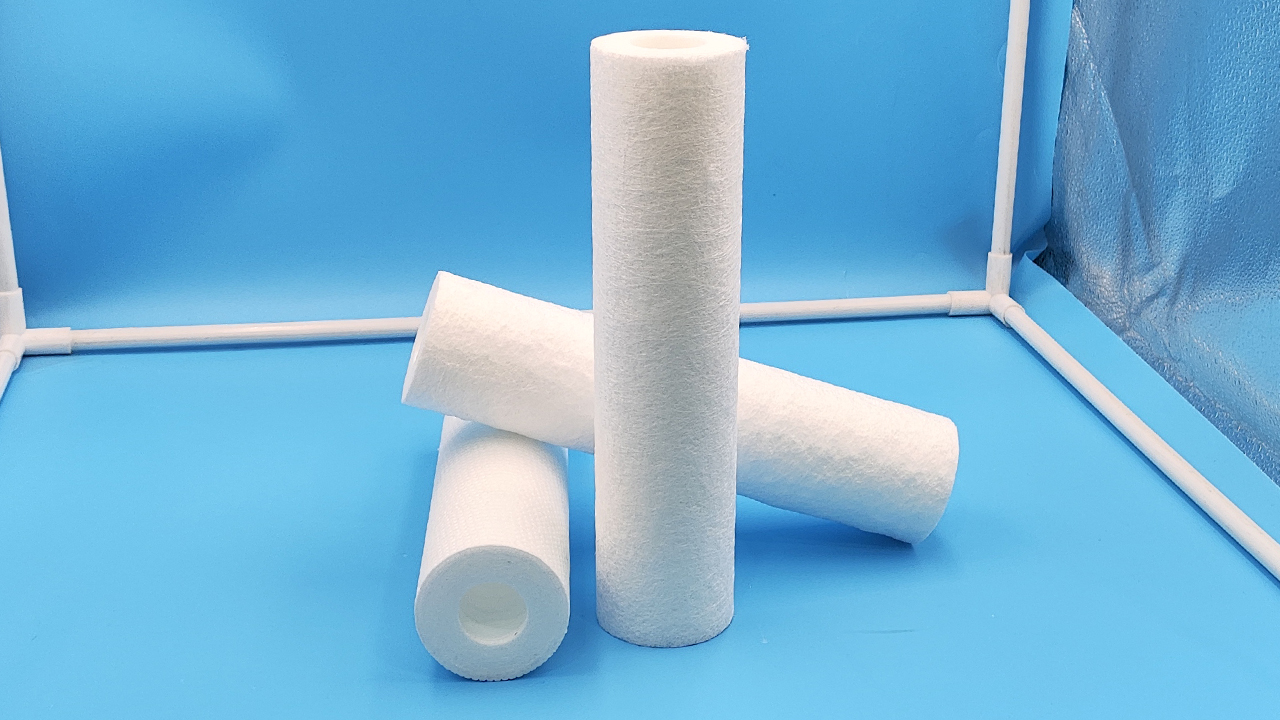

Choosing the Right 1 Micron Spun Filter

When selecting a 1 Micron Spun Filter, it is essential to consider factors such as flow rate, compatibility with your liquid, and filter material. Different applications may require specific materials, such as polypropylene or polyester, which can withstand varying temperatures and chemical exposures.

Furthermore, evaluating the filter’s specifications, including pressure ratings and dirt-holding capacity, will help you determine the best option for your needs. Consulting with a filtration expert can provide valuable insights and recommendations tailored to your specific application.

Maintenance Tips for Optimal Performance

To ensure the longevity and effectiveness of your 1 Micron Spun Filter, regular maintenance is crucial. This includes monitoring the pressure drop across the filter, which can indicate when it needs to be replaced. Keeping a log of filter performance can help in establishing a preventative maintenance schedule.

In addition, proper installation is vital in maximizing the filter’s efficiency. Ensuring the filter is securely in place and free from leaks will prevent bypassing of unfiltered liquids, maintaining the quality of your end product.