In commercial and light industrial reverse osmosis systems, membrane efficiency and operating pressure directly influence overall system performance and energy consumption. ULP Reverse Osmosis Membrane Elements are specifically engineered to deliver stable desalination results under ultra-low operating pressure, making them suitable for energy-sensitive and space-constrained installations.

For standard 4-inch pressure vessel systems, the ULP31-4040 spiral wound RO element ultra low pressure configuration provides a balanced combination of productivity, structural reliability, and energy efficiency.

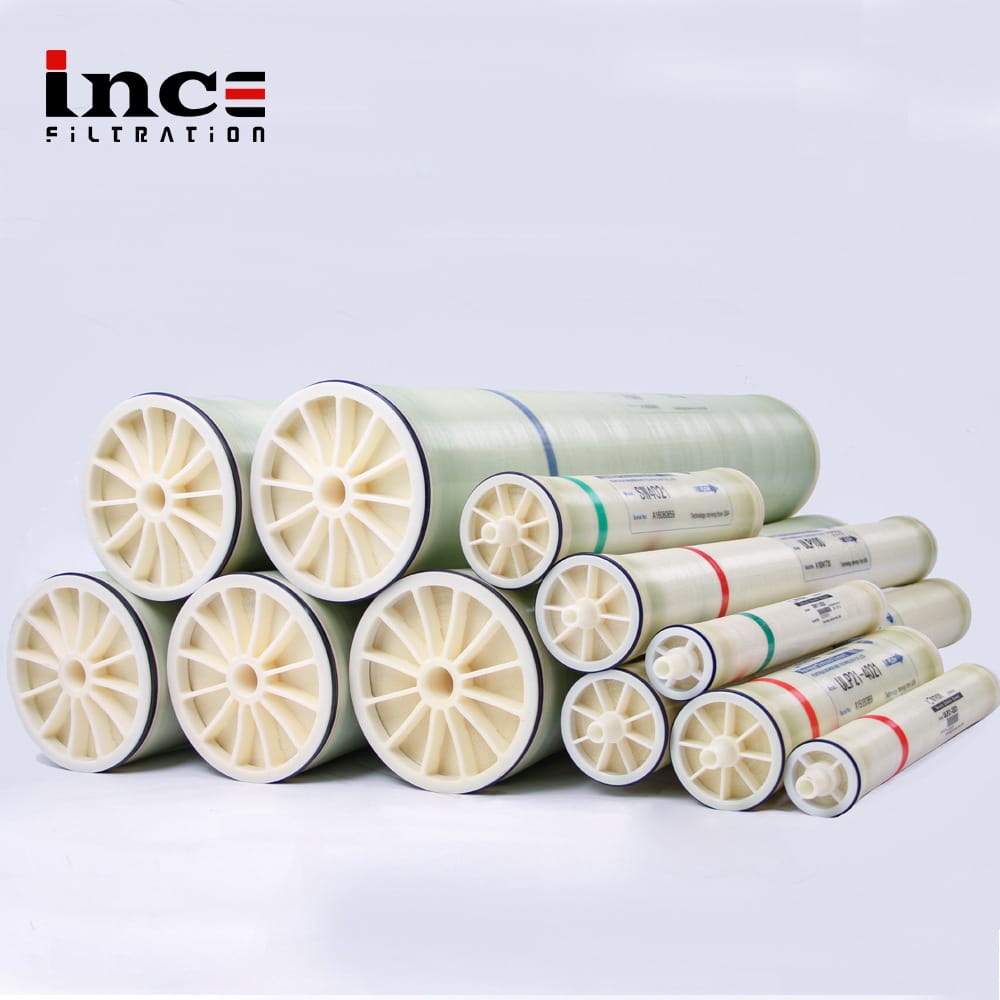

Reverse osmosis membranes commonly use spiral wound architecture due to its compact structure and high membrane surface area within a cylindrical format. The ULP31-4040 spiral wound RO element ultra low pressure adopts this proven design, integrating membrane sheets, feed spacers, and permeate carriers into a tightly wound assembly around a central permeate tube.

This structure offers:

Efficient flow distribution

High packing density for increased surface area

Controlled pressure drop

Stable mechanical performance

The spiral wound configuration maximizes permeate production within a standard 4040 housing while maintaining structural durability during continuous operation.

The ULP31 series utilizes a high-permeability thin-film composite (TFC) polyamide membrane layer. This material enhances water flux while preserving reliable salt rejection characteristics.

By operating efficiently at reduced feed pressure, the ULP31-4040 spiral wound RO element ultra low pressure helps:

Lower pump energy requirements

Reduce operating costs

Minimize mechanical stress on system components

Improve overall system energy efficiency

This makes it particularly suitable for applications using municipal tap water, low-salinity groundwater, or properly pretreated surface water.

The 4040 format (4-inch diameter × 40-inch length) is widely used in:

Commercial RO systems

Food and beverage processing support systems

Pharmaceutical auxiliary water treatment

Laboratory water purification units

Small-scale industrial process water systems

The ULP31-4040 spiral wound RO element ultra low pressure is compatible with standard 4-inch pressure vessels, allowing straightforward installation and membrane replacement without system modification.

Multiple 4040 elements can be arranged in series or parallel to scale production capacity according to project requirements.

Consistency in membrane manufacturing is essential for predictable system performance. The ULP31-4040 element is produced with controlled membrane sheet alignment and uniform winding density to ensure even flow distribution and manageable pressure drop.

When integrated with appropriate pretreatment—such as multimedia filtration and cartridge filtration—the ULP31-4040 spiral wound RO element ultra low pressure provides:

Stable permeate flow

Reliable salt rejection

Controlled differential pressure

Gradual and monitorable performance changes over time

This predictability supports planned cleaning cycles and minimizes unexpected downtime.

For OEM manufacturers, system integrators, and facility operators seeking to balance efficiency and reliability, ULP Reverse Osmosis Membrane Elements offer a technically sound solution. The ULP31-4040 spiral wound RO element ultra low pressure combines compact design, low-pressure operation, and dependable desalination performance.

Its compatibility with standard 4040 housings and its ability to operate efficiently at reduced pressure make it a practical choice for commercial and light industrial reverse osmosis systems focused on long-term cost control and operational stability.

EMAIL: sales6@incefiltration.com

Mobile/WhatsApp: +86 138 0321 9803

TEL: +86 (311) 8968 1588

TIME: Monday-Friday 8:00am - 5:30pm (CST)