Trusted PP Meltblown Filter for Sediment Control

# Trusted PP Meltblown Filter for Sediment Control

What is a PP Meltblown Filter?

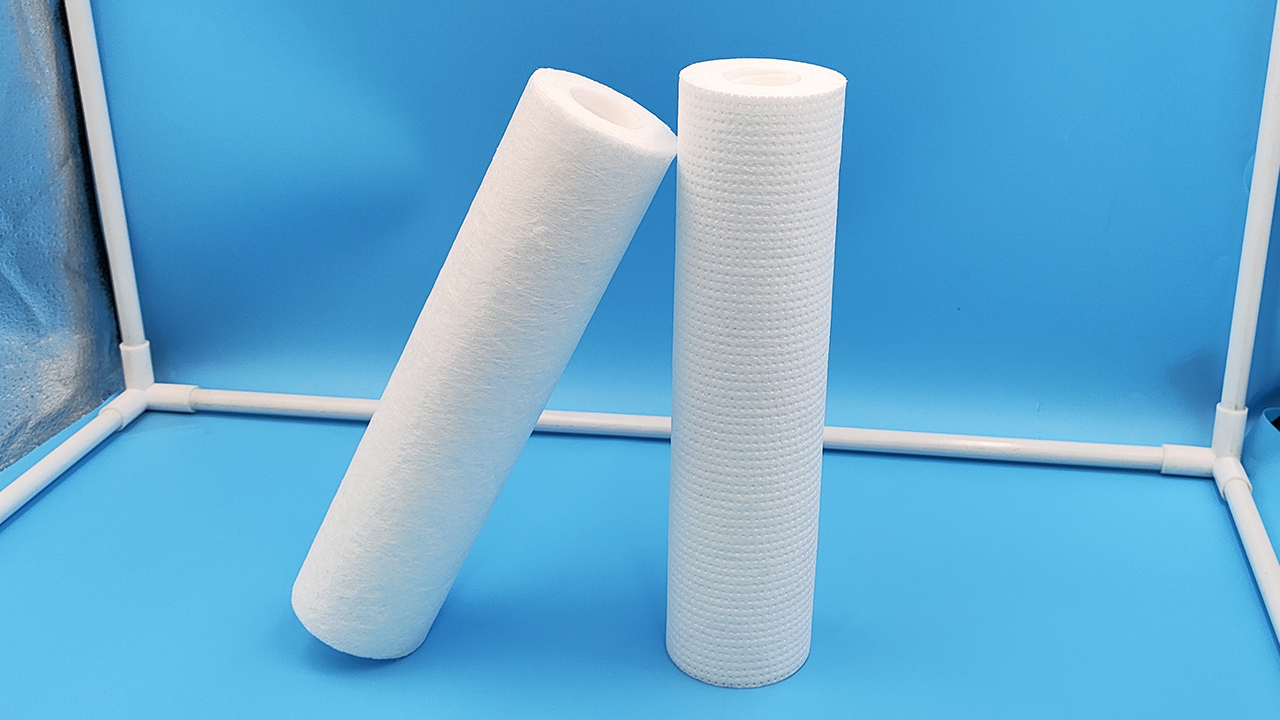

The PP meltblown filter is engineered specifically for effective sediment control, utilizing advanced meltblown technology to trap particles efficiently. This type of filter is made from polypropylene (PP) fibers, which are known for their durability and excellent filtration capabilities. The meltblown process ensures that the fibers are randomly arranged, creating a dense mat that captures a wide range of sediment sizes.

In various applications, including water treatment and industrial processes, these filters play a crucial role in maintaining water clarity and preventing equipment damage caused by sediment buildup. Their effectiveness makes them a trusted choice for many industries looking to enhance their filtration systems.

Key Benefits of Using PP Meltblown Filters

One of the primary benefits of using PP meltblown filters is their high dirt-holding capacity. This means they can capture more sediment before needing replacement, resulting in lower maintenance costs and longer service life. With their ability to filter out particles as small as 1 micron, these filters provide superior protection for downstream equipment and processes.

Additionally, PP meltblown filters are resistant to chemical corrosion and can handle a wide range of temperatures. This versatility makes them suitable for various environments, whether it’s in municipal water treatment facilities or industrial manufacturing plants. Choosing the right filter can greatly improve operational efficiency and reduce downtime.

Applications of PP Meltblown Filters

PP meltblown filters are widely used in numerous applications due to their reliable performance. In the water treatment industry, they are essential for removing sediments from drinking water sources, ensuring safe and clean water for consumption. Their ability to maintain high flow rates while effectively filtering out contaminants makes them ideal for both residential and commercial use.

In industrial settings, these filters protect critical machinery from abrasive particles. By incorporating PP meltblown filters into the system, companies can extend the lifespan of their equipment and reduce repair costs. Whether you’re dealing with wastewater treatment or cooling water filtration, these filters provide an efficient solution for sediment control.

Why Choose Our Trusted PP Meltblown Filters?

Our trusted PP meltblown filters stand out in the market due to their exceptional quality and reliability. Manufactured under strict quality control standards, these filters guarantee consistent performance and durability. We prioritize customer satisfaction and ensure our products meet the highest industry benchmarks.

When you choose our filters, you’re not just purchasing a product; you’re investing in peace of mind. With our extensive support and expertise, we help you select the right filter that meets your specific needs. Experience the difference with our trusted PP meltblown filters for sediment control today!

How to Maintain Your PP Meltblown Filters

Maintaining your PP meltblown filters is essential for ensuring optimal performance. Regular monitoring of pressure drops across the filter can indicate when it’s time for a replacement. A sudden increase in pressure drop may suggest that the filter is becoming clogged with sediment.

Additionally, following the manufacturer’s guidelines for installation and maintenance will help extend the lifespan of your filters. Proper handling ensures that the integrity of the filter media remains intact, allowing for maximum filtration efficiency. Invest in regular maintenance to keep your filtration system performing at its best.