String Wound Filter Cartridge Material and Structural Design for Industrial Filtration

A String Wound Filter Cartridge is widely applied in industrial and commercial filtration systems where stable sediment control and predictable performance are required. Its long-standing use is closely tied to the flexibility of its material options and the reliability of its wound structure. Understanding how material selection and structural design influence filtration behavior is essential for engineers and procurement teams evaluating filtration solutions for different operating conditions.

In many installations, a String Wound Sediment Filter Cartridge serves as a primary filtration stage, protecting downstream equipment from particulate contamination. Over time, consistent material quality also plays a decisive role in String Wound Filter Cartridge Replacement planning, ensuring that performance remains stable across multiple service cycles.

Structural Principles of String Wound Filter Cartridges

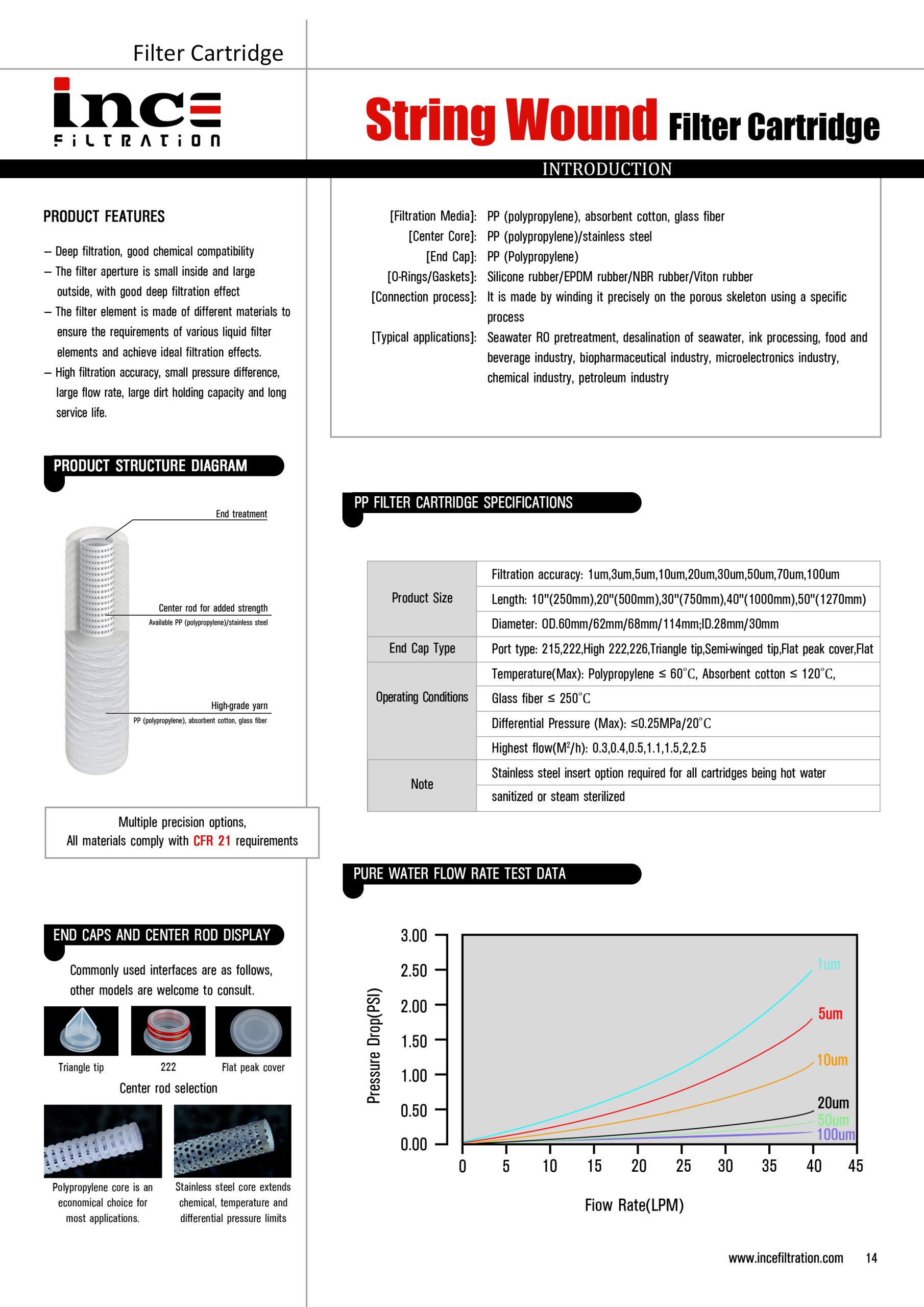

The defining feature of a String Wound Filter Cartridge is its depth filtration structure. Filtration yarn is wound in precise layers around a rigid core, forming a gradient density from the outer surface toward the center. This structure allows larger particles to be captured first, while finer contaminants are retained deeper within the cartridge body.

This progressive density design distributes contaminant loading throughout the entire media volume rather than concentrating it on the surface. As a result, pressure increase occurs more gradually, supporting longer operating cycles and more predictable maintenance schedules. For applications with fluctuating solids content, this structural characteristic is often preferred over surface-type filtration elements.

Core design is another structural consideration. Cartridges may be produced with polymer cores or reinforced cores depending on pressure and temperature requirements. The interaction between the wound media and the core directly affects dimensional stability, especially during extended operation or under variable differential pressure.

Polypropylene, Cotton, and Glass Fiber Media Options

Material selection significantly affects chemical compatibility and filtration stability. A polypropylene string wound filter cartridge is commonly chosen for water treatment and chemical process applications due to its broad chemical resistance and low extractables. Polypropylene fibers also maintain consistent performance across a wide pH range, making them suitable for many industrial fluids.

In contrast, a cotton string wound filter cartridge is often applied in systems handling oils, solvents, or fluids where natural fiber compatibility is advantageous. Cotton media provides good absorption characteristics and is sometimes specified where temperature resistance and mechanical softness are beneficial to the process.

For higher temperature or more demanding environments, a glass fiber string wound filter cartridge offers enhanced thermal resistance and dimensional stability. Glass fiber media maintains its structure under conditions that may challenge polymer-based fibers, making it suitable for specialized industrial filtration scenarios where operating conditions are more severe.

Core Materials and Reinforced Structural Designs

Beyond the filtration media itself, the core material contributes significantly to overall cartridge integrity. A string wound filter cartridge PP core is widely used in standard industrial applications, offering a balance of chemical resistance, mechanical strength, and cost efficiency. Polypropylene cores integrate well with polypropylene media, providing uniform expansion behavior under pressure.

In applications involving higher differential pressure or mechanical stress, a string wound filter cartridge with stainless steel core may be specified. Stainless steel cores provide superior structural reinforcement, reducing the risk of deformation during operation. This design is particularly valuable in high-flow systems or where pressure fluctuations are frequent.

The choice between polymer and metal cores often depends on system design and long-term operating expectations. Matching the core material to the filtration media and process conditions supports consistent performance and extends service life, especially in continuous-duty filtration systems.

Implications for Replacement and Operational Consistency

Material and structural consistency are critical factors during String Wound Filter Cartridge Replacement. Using cartridges with different fiber types or core materials than the original specification can alter pressure drop behavior and filtration efficiency. Maintaining the same construction parameters helps ensure predictable system performance after each change-out.

A String Wound Sediment Filter Cartridge designed with controlled winding tension and consistent material quality reduces variability across production batches. This consistency simplifies maintenance planning and allows operators to rely on established replacement intervals rather than responding to unexpected pressure increases.

From a procurement perspective, evaluating material options alongside structural features supports informed decision-making. By aligning cartridge media and core design with system requirements, operators achieve reliable sediment removal while minimizing operational disruption and long-term maintenance costs.