String Wound Filter Cartridge for Reliable Sediment Control

In many industrial and commercial water systems, stable sediment removal is a practical necessity rather than a luxury. A String Wound Filter Cartridge provides a predictable, depth‑style filtration approach that meets this need, especially where particles, rust, or debris can damage downstream equipment or shorten the life of finer filters. Selecting the right cartridge and planning for timely String Wound Filter Cartridge Replacement are both essential to keep systems running smoothly without unexpected pressure spikes or downtime.

A well‑designed string wound cartridge is also used as a first‑stage barrier, giving later stages a cleaner feed and lowering overall maintenance efforts. For buyers who seek a proven, versatile filtration element, understanding how these cartridges work, which sizes fit their housings, and what to check at replacement time helps make procurement decisions more confident and cost‑effective.

Depth filtration principle and performance characteristics

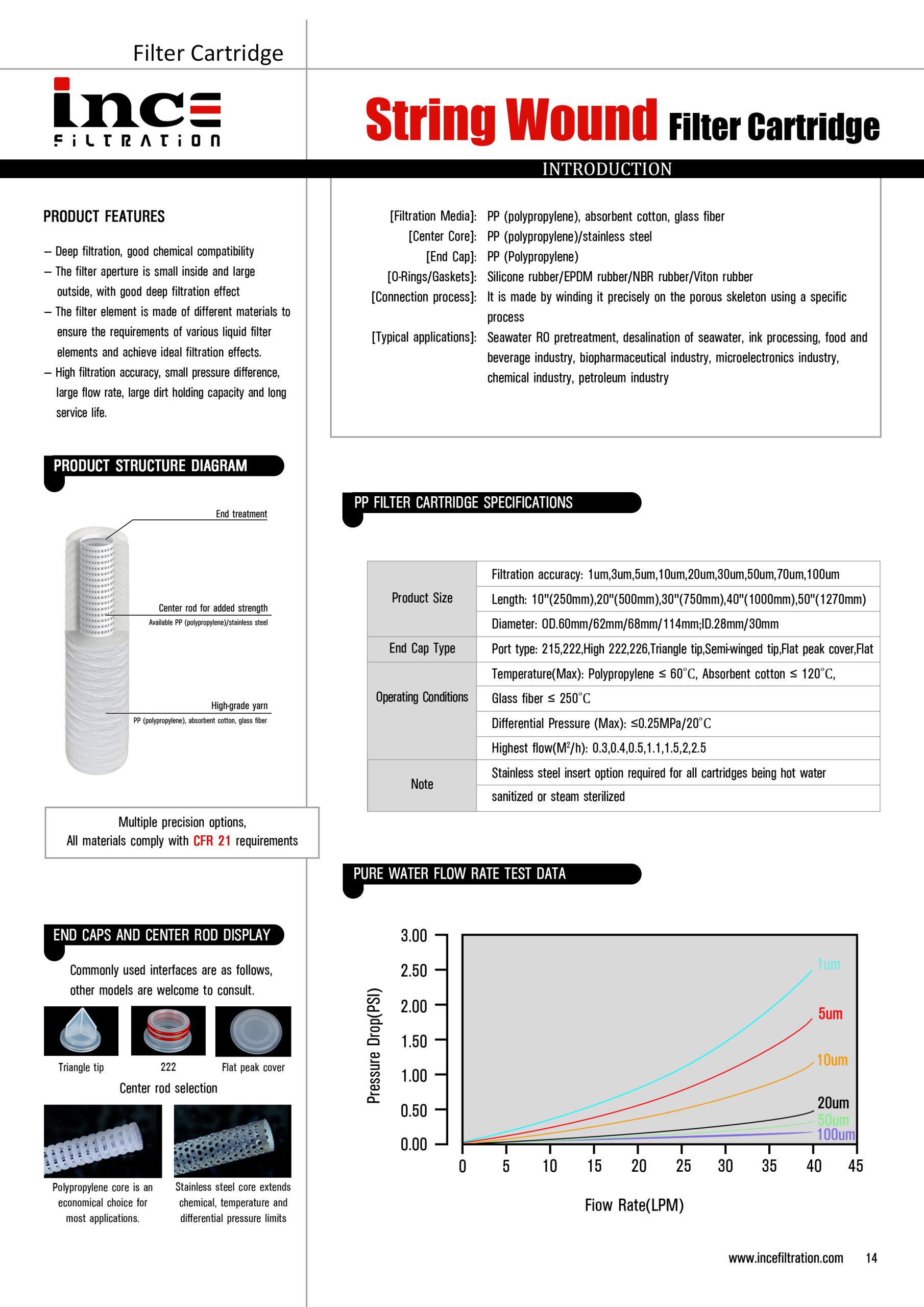

String wound cartridges function as true depth filters, where fibers are wound around a core to create multiple layers of particle capture. This structure is deliberately designed to trap larger particles near the exterior and finer debris deeper inside, rather than only on the surface. That layered capture mechanism is well documented for string wound depth filters, which emphasize controlled particle removal and a large dirt‑holding capacity.

The winding pattern and gradual density of the media support steadier pressure behavior during service. As fluid flows through the cartridge, the gradient density reduces the chance of sudden clogging at one point, spreading the load through the depth of the element. This characteristic makes String Wound Sediment Filter Cartridge designs suitable where solids content varies and where longer service intervals are desirable.

Material choices and manufacturing quality further influence performance stability. Common inner cores and yarn types can include polypropylene, glass fiber, or cotton, wound with precise tension to meet application needs. The result is a cartridge that retains its form under normal differential pressures and maintains consistent filtration across repeat cycles, qualities buyers typically look for when comparing depth cartridges for water or process protection.

Application scenarios and size compatibility

String wound cartridges are used in a broad range of systems where sediment control protects downstream stages or critical equipment. Typical use cases include pre‑filtration before membranes, softeners, or polishing units in water treatment, as well as protection for pumps, heat exchangers, and spray systems in manufacturing. Because the cartridge captures both coarse and fine particles through its depth structure, it is appropriate for mixed debris loads commonly seen in industrial and municipal settings.

Size and standard model compatibility matter for seamless integration. Many housings accept cartridges in standardized lengths such as 10 inch string wound filter cartridge or 20 inch string wound filter cartridge, which work well in compact or moderate‑flow systems. For larger or higher‑volume installations, 30 inch, 40 inch, or 50 inch string wound filter cartridge formats provide more media area, longer service life, and reduced frequency of change‑outs. These size options help buyers match cartridge length to flow demands without redesigning housings or systems.

Adherence to string wound filter cartridge standard size specifications is important for avoiding bypass, ensuring a proper seal, and maintaining predictable pressure drop. When system operators choose cartridges that fit recognized standard dimensions, they reduce installation risk and simplify inventory and replacement logistics, especially across multiple sites or varied equipment.

Replacement planning and procurement guidance

A planned String Wound Filter Cartridge Replacement strategy keeps filtration performance consistent and prevents operational surprises. Key considerations include flow rate requirements, contaminant type and load, and allowable pressure drop. For systems with fluctuating solids or seasonal debris spikes, specifying a slightly larger size or a cartridge with higher dirt‑holding capacity can extend service intervals without compromising filtration effectiveness.

Consistency between original and replacement cartridges is another critical point. Differences in winding density, yarn quality, or core material can change pressure behavior or retention efficiency. Buyers should prioritize cartridges produced with controlled material quality and precise winding processes to maintain predictable outcomes from one replacement to the next.

Evaluating suppliers also involves checking dimensional accuracy, media uniformity, and manufacturing controls. Cartridges that meet these standards deliver dependable performance, reduce unplanned maintenance, and support long‑term cost control. Selecting the correct size—be it 10, 20, 30, 40, or 50 inch—alongside appropriate micron rating ensures that each replacement aligns with system design and operational goals.

Selection advice for engineers and purchasing teams

When choosing among string wound options, focus first on application needs rather than marketing claims. Confirm the housing dimensions, expected flow, and particle types present in the feed. If the system frequently handles coarse debris or rust, a cartridge with robust depth media and higher holding capacity is often more practical than one intended purely for finer polishing.

Next, verify that the cartridge size and end‑cap style match the housing. Standard lengths such as 20 inch or 30 inch are commonly stocked and easier to source, while 40 inch or 50 inch formats deliver longer life in high‑volume systems. Where space is constrained, 10 inch cartridges can be effective in smaller housings, though service intervals may be shorter under heavy load.

Finally, consider supplier quality and replacement consistency. A reliable String Wound Filter Cartridge from a manufacturer that maintains tight production controls reduces variability and supports stable filtration performance over time. For operators focused on protecting downstream equipment, minimizing downtime, and achieving practical maintenance schedules, choosing the right string wound cartridge and setting an informed replacement plan delivers practical value more than chasing marginal cost differences.