Compared with surface-type sediment filters, a String Wound Sediment Filter Cartridge distributes solids throughout the cartridge body. This design reduces the risk of rapid surface blockage and allows more uniform utilization of the filter media. The winding tension and fiber overlap are carefully controlled to balance filtration efficiency with flow stability, ensuring predictable performance under normal industrial operating conditions.

Material selection further defines performance characteristics. Polypropylene fibers are commonly used for general water and chemical compatibility, while cotton or specialized fibers may be selected for applications with specific temperature or fluid requirements. The core, typically polypropylene or stainless steel, provides mechanical strength and dimensional stability during extended service.

Key Performance Advantages in Real Operation

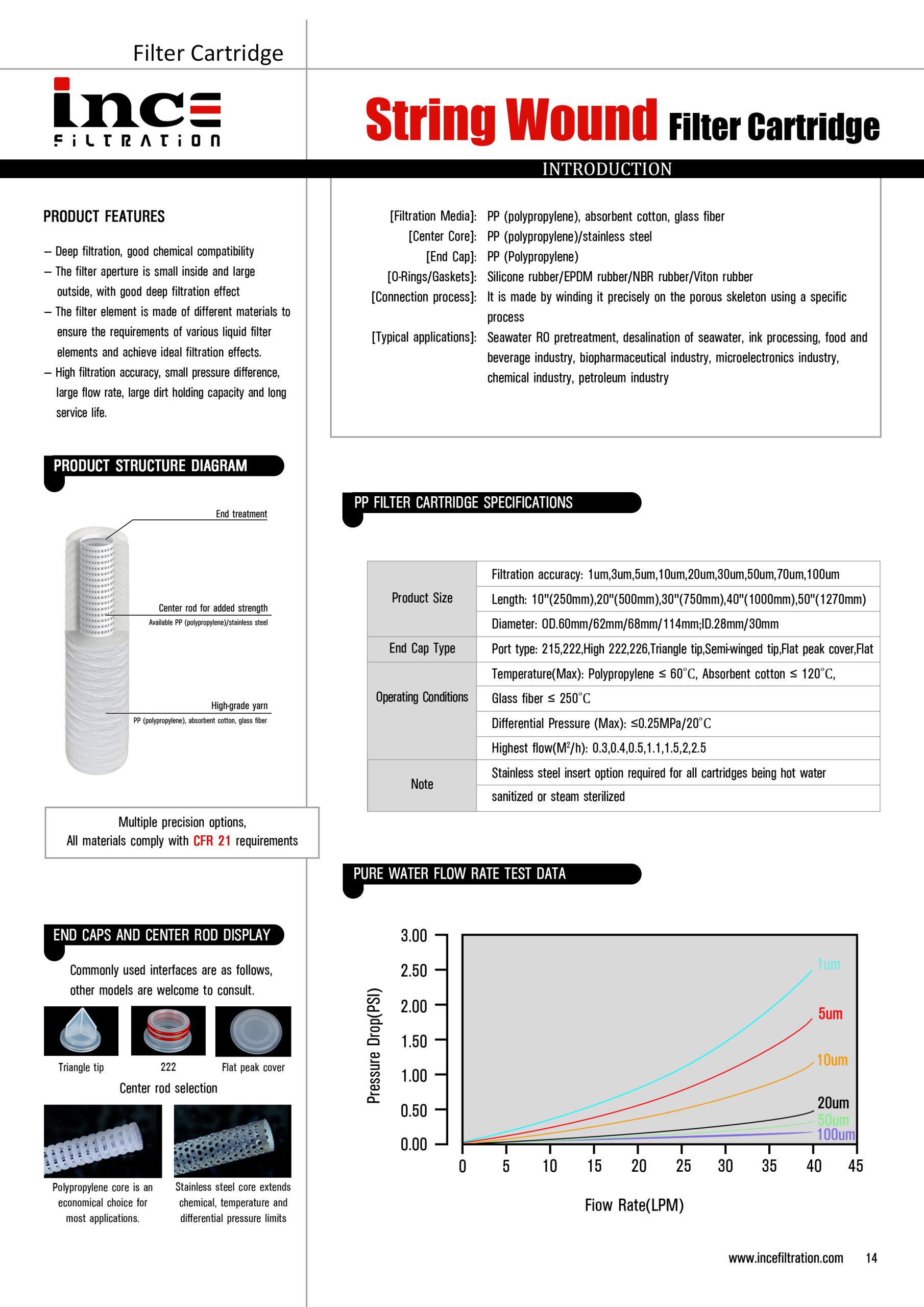

One of the most valued advantages of a String Wound Filter Cartridge is consistent filtration efficiency over time. The depth structure supports nominal ratings ranging from a 1 micron string wound filter cartridge for fine particulate control to a 100 micron string wound filter cartridge for coarse prefiltration. This flexibility allows engineers to match filtration precision to system requirements without overengineering.

Service life is another important consideration. By retaining contaminants throughout the full depth of the cartridge, the filter resists premature clogging and maintains usable flow for longer periods. This is particularly relevant when selecting a string wound filter cartridge 5 micron for applications where influent quality varies and sudden pressure increases must be avoided.

Operational predictability also benefits system management. Pressure drop increases gradually rather than abruptly, allowing maintenance teams to plan replacements based on performance trends. For procurement teams, this predictability simplifies replacement scheduling and reduces the risk of unexpected downtime associated with emergency filter changes.

Typical Application Scenarios

String wound cartridges are widely used in pretreatment stages across multiple industries. In water treatment and reverse osmosis systems, they serve as effective sediment barriers, protecting downstream membranes from fouling. A 10 micron string wound filter cartridge or 5 micron string wound filter cartridge is often selected depending on feed water quality and system sensitivity.

In chemical processing, stable filtration is essential to protect pumps, valves, and downstream equipment. A String Wound Filter Cartridge provides reliable particle retention while maintaining chemical compatibility, making it suitable for handling process water, solvents, and intermediate fluids. For oil filtration systems, the depth structure efficiently captures fine solids without excessive pressure loss, supporting steady flow conditions.

Food and beverage operations use these cartridges for general liquid clarification and equipment protection, where consistency and material reliability are critical. In electronics manufacturing and other precision industries, fine ratings such as a 1 micron string wound filter cartridge help control particulate contamination before polishing filtration stages.

Filtration Precision and Specification Flexibility

Procurement decisions often require balancing filtration accuracy with operational tolerance. String wound cartridges are available in a broad range of micron ratings, including 5 micron, 10 micron, 20 micron string wound filter cartridge options for standard industrial use, as well as 50 micron string wound filter cartridge selections for coarse solids removal.

This range allows system designers to specify filtration levels that align with actual process requirements rather than relying on a one-size-fits-all approach. By selecting the appropriate rating, users can protect downstream equipment while avoiding unnecessary pressure loss or shortened service life associated with overly fine filtration.

The consistent manufacturing process ensures that nominal ratings perform predictably across production batches, which is especially important for buyers managing multiple systems or facilities with standardized filtration specifications.

Operational Efficiency and Cost Considerations

From a lifecycle perspective, the value of a String Wound Filter Cartridge lies in its operational efficiency rather than initial purchase price. Longer service intervals reduce the frequency of filter replacement, lowering labor involvement and minimizing process interruptions. This is particularly important in continuous operations where downtime carries significant indirect costs.

Stable pressure behavior also contributes to energy efficiency. Pumps operate within predictable ranges, avoiding excessive energy consumption caused by sudden flow restrictions. Over time, this stability supports better control of operating expenses and system performance.

For procurement teams, standardization further enhances efficiency. Selecting consistent specifications simplifies inventory management and allows for easier substitution when a string wound filter cartridge replacement is required. This reduces the risk of compatibility issues and helps maintain uninterrupted supply.

Compatibility, Replacement, and Quality Consistency

Compatibility with existing housings is a key requirement in industrial filtration. String wound cartridges are manufactured in standard diameters and lengths, enabling straightforward integration into commonly used filter housings. This compatibility is particularly important when replacing older elements without modifying system hardware.

When evaluating a string wound filter cartridge replacement, buyers often look for consistent dimensions, stable filtration behavior, and reliable sealing performance. Standardized production processes and controlled quality inspection help ensure that replacement cartridges perform as expected, reducing variability risk.

Consistent quality control also supports long-term procurement planning. Uniform fiber winding, material traceability, and dimensional accuracy contribute to predictable performance across repeated orders, reinforcing confidence in supply continuity.

Closing Paragraph

A well-designed String Wound Filter Cartridge provides dependable depth filtration for a wide range of industrial applications. Its stable performance, flexible micron ratings, and compatibility with standard systems make it a practical choice for procurement teams focused on long-term reliability rather than short-term optimization. By supporting controlled maintenance schedules, predictable operation, and straightforward replacement, this filtration solution continues to play a reliable role in modern liquid filtration systems where consistency and operational confidence are essential.