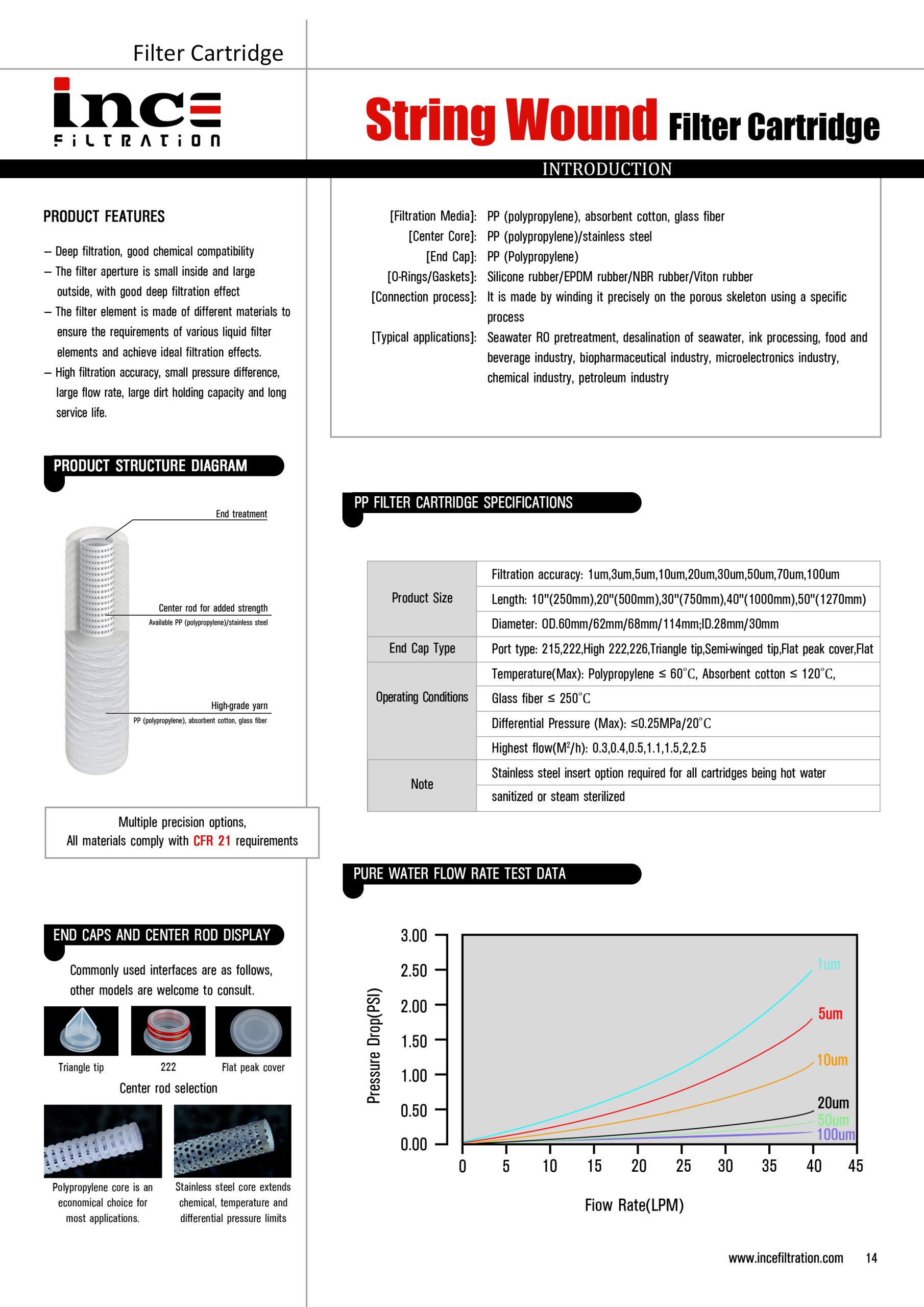

String Wound Filter Cartridge Applications Across Industrial Filtration Systems

A String Wound Filter Cartridge is commonly used in liquid filtration systems where stable sediment removal and predictable performance are required under varying operating conditions. Its depth filtration structure allows it to handle fluctuating particle loads, making it suitable for a wide range of industrial processes that rely on consistent pre-filtration or process protection.

In many industries, a String Wound Sediment Filter Cartridge is selected as an initial filtration stage to protect membranes, pumps, valves, and downstream precision filters. As operating cycles extend and system reliability becomes a priority, proper planning for String Wound Filter Cartridge Replacement plays an important role in maintaining long-term filtration efficiency and operational stability.

Water Treatment and Desalination Applications

In water treatment systems, a string wound filter cartridge for RO pretreatment is widely used to remove suspended solids, rust, and particulate matter before water enters reverse osmosis membranes. By reducing fouling potential at the pretreatment stage, these cartridges help extend membrane service life and stabilize operating pressure across the system.

A string wound filter cartridge for seawater desalination serves a similar protective role under more demanding conditions. Seawater often contains sand, silt, and organic debris that can quickly overload surface filters. The depth structure of a String Wound Filter Cartridge distributes contaminant loading throughout the media, supporting longer run times and more predictable pressure behavior in desalination pretreatment lines.

In both applications, dimensional consistency and material compatibility are essential. Using cartridges that meet standard specifications simplifies maintenance and ensures that replacement elements perform consistently with the original design intent.

Chemical and Oil Processing Environments

A string wound filter cartridge for chemical industry applications is valued for its structural stability and adaptability to different process fluids. Chemical processing often involves varying concentrations of suspended solids, and the depth filtration mechanism helps manage these variations without sudden pressure spikes. Proper media selection further ensures compatibility with process chemicals.

In petroleum and lubricant systems, a string wound filter cartridge for oil filtration is commonly used to remove particulate contaminants from fuels, hydraulic oils, and lubricants. The wound fiber structure provides mechanical strength that supports operation under higher viscosity conditions, while capturing debris that could otherwise damage equipment or reduce product quality.

For both chemical and oil filtration, maintaining consistency during String Wound Filter Cartridge Replacement is critical. Changes in winding density or core construction can alter flow behavior, making standardized replacement practices an important part of system management.

Food, Beverage, and Pharmaceutical Processing

In the food and beverage sector, a string wound filter cartridge for food and beverage applications is often installed to remove particulates from water, syrups, and process liquids. Depth filtration helps capture a broad range of particle sizes, supporting product clarity and protecting downstream polishing filters without introducing excessive pressure loss.

A string wound filter cartridge for pharmaceutical industry use is typically applied in non-critical pre-filtration stages, where the goal is to protect more precise filtration or sterilization steps. Consistent fiber structure and controlled manufacturing are essential to ensure predictable performance and minimize the risk of particulate release during operation.

In regulated industries, documentation and repeatability are key considerations. Using a String Wound Sediment Filter Cartridge with consistent materials and dimensions simplifies validation and supports stable production conditions.

Specialty Manufacturing and Electronics Applications

In printing and coating processes, a string wound filter cartridge for ink filtration is used to remove gels, agglomerates, and particulates that can affect print quality or clog fine nozzles. The depth design allows ink to be filtered gently, reducing the risk of sudden blockage while maintaining consistent flow.

A string wound filter cartridge for electronics industry applications is often applied in ultrapure water pretreatment or process fluid filtration. By controlling particulate levels early in the filtration chain, these cartridges help protect sensitive downstream equipment and maintain stable operating conditions in precision manufacturing environments.

Across these diverse applications, the versatility of the String Wound Filter Cartridge lies in its adaptable structure and proven filtration behavior. When correctly specified and replaced on schedule, it supports reliable operation in systems ranging from water treatment to advanced manufacturing.