Standard Melt Blown Cartridges for Sediment Removal in Liquid Filtration

# Standard Melt Blown Cartridges for Sediment Removal in Liquid Filtration

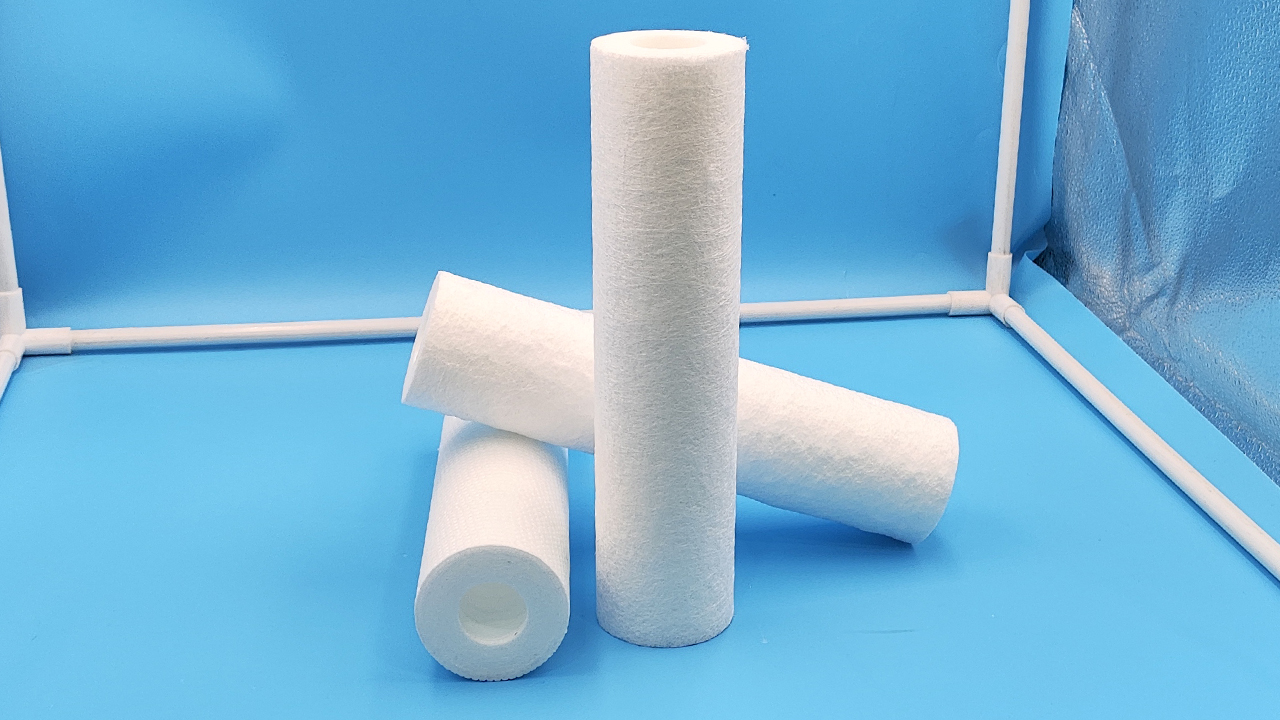

What Are Standard Melt Blown Cartridges?

Standard melt blown cartridges are an essential component in the liquid filtration process, designed specifically for sediment removal. These cartridges are made from high-quality polypropylene fibers that are thermally bonded to create a dense yet porous structure. This unique design allows them to effectively capture and retain particulate matter, ensuring that only clean, sediment-free liquids pass through.

The effectiveness of standard melt blown cartridges lies in their ability to filter out various contaminants, including sand, silt, and rust particles. By utilizing advanced melt-blown technology, these cartridges provide a high dirt-holding capacity while maintaining low pressure drop, making them ideal for both industrial and residential applications.

Benefits of Using Melt Blown Cartridges

One of the primary benefits of using standard melt blown cartridges is their superior filtration efficiency. They are engineered to deliver consistent performance over extended periods, which means fewer replacements and lower maintenance costs. This makes them a cost-effective solution for businesses and homeowners alike.

Additionally, these cartridges are available in a variety of micron ratings, allowing users to choose the right level of filtration based on their specific needs. Whether you’re dealing with water purification, food and beverage processing, or industrial applications, there’s a melt blown cartridge suited for your requirements.

Applications of Standard Melt Blown Cartridges

Standard melt blown cartridges find extensive use across various industries due to their versatility. In municipal water treatment facilities, they play a critical role in ensuring the safety and quality of drinking water by removing harmful sediments and pollutants.

In the pharmaceutical and food industries, these cartridges help maintain compliance with stringent health regulations by guaranteeing that the liquids processed are free from any solid contaminants. Their reliability and efficiency make them a preferred choice for many professionals aiming to enhance product quality and safety.

Choosing the Right Cartridge for Your Needs

When selecting standard melt blown cartridges for sediment removal, it’s important to consider factors such as flow rate, temperature, and chemical compatibility. Understanding these parameters will help you select the best cartridge that meets your operational requirements.

Moreover, always opt for cartridges that come with manufacturer specifications and certifications. This ensures that the products not only meet industry standards but also provide peace of mind regarding their performance and longevity. Investing in high-quality melt blown cartridges can significantly enhance your filtration system’s overall efficiency.

Maintenance Tips for Optimal Performance

To ensure that your standard melt blown cartridges perform optimally, regular maintenance is crucial. Monitor the pressure drop across the cartridge regularly; a significant increase may indicate that the cartridge is clogged and needs replacement.

Also, keep an eye on the quality of the filtered liquid. Discoloration or unusual taste can be signs that the cartridge has reached the end of its life cycle. Timely replacement will not only extend the lifespan of your filtration system but also ensure that you consistently receive clean, sediment-free liquids.