SS316L Bag Filter Housing with EPDM Gasket for Industrial Filtration

In many industrial liquid filtration systems, stable operation and secure sealing are critical factors that directly affect process safety and filtration efficiency. As filtration media become more aggressive and operating conditions more complex, users increasingly rely on robust housing solutions that can withstand chemical exposure and continuous operation. The SS316L Bag Filter Housing with EPDM Gasket is designed to meet these requirements by combining corrosion-resistant stainless steel construction with reliable elastomer sealing performance.

Product Overview and Core Design Concept

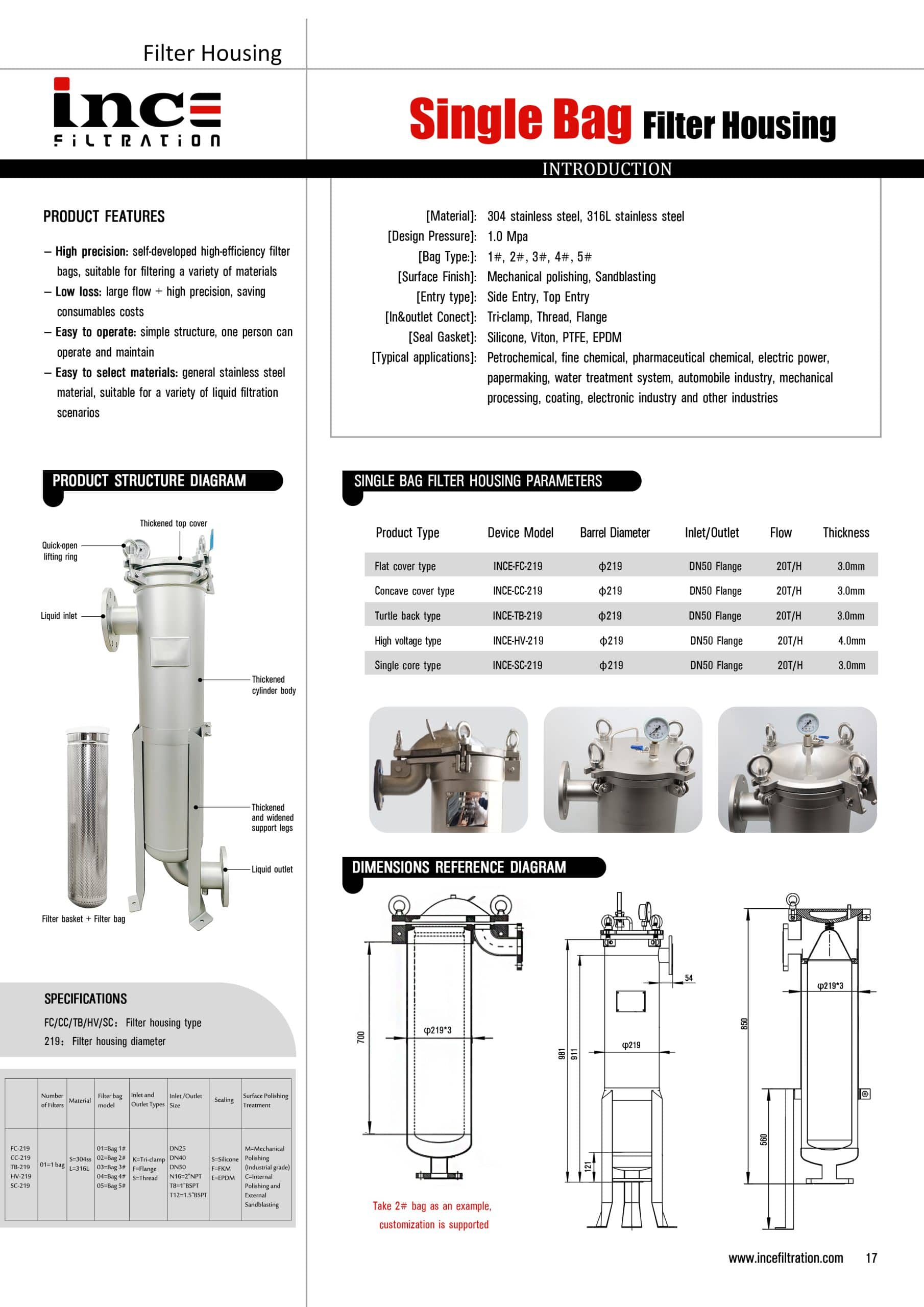

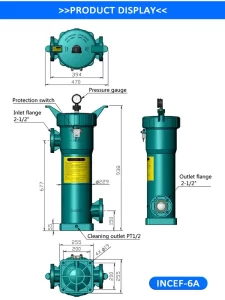

A SS316L Bag Filter Housing with EPDM Gasket is a pressure-rated filtration vessel engineered to support liquid filter bags used for removing suspended solids from process fluids. The housing body is manufactured from 316L stainless steel, a low-carbon alloy known for its enhanced resistance to corrosion and its suitability for industrial filtration environments.

The internal structure supports standard filter bags with a perforated basket that maintains bag shape during operation. The EPDM Gasket is installed at the sealing interface between the housing cover and body, forming a tight closure that prevents leakage and ensures controlled flow through the filter media. This design allows the housing to function as a reliable component within various industrial filtration systems.

As a result, the SS316L Bag Filter Housing with EPDM Gasket serves as a versatile filtration solution for processes requiring consistent liquid quality and secure containment.

Material Selection for Industrial Reliability

Material choice plays a decisive role in the long-term performance of a SS316L Bag Filter Housing with EPDM Gasket. SS316L stainless steel contains molybdenum, which improves resistance to chlorides and many corrosive chemicals commonly encountered in industrial processes. Its low carbon content reduces the risk of corrosion at welded joints, supporting structural integrity over extended service periods.

The EPDM Gasket complements the stainless steel housing by providing elasticity, resilience, and resistance to water-based fluids and many mild chemicals. In applications where temperature variations and pressure cycling occur, EPDM helps maintain sealing consistency without rapid degradation.

Together, SS316L stainless steel and EPDM sealing materials form a balanced combination that supports stable filtration performance in demanding industrial environments.

Key Performance Advantages in Filtration Systems

One major advantage of a SS316L Bag Filter Housing with EPDM Gasket is its ability to maintain sealing integrity under continuous operation. The gasket design ensures uniform compression across the sealing surface, reducing the risk of bypass or external leakage during filtration.

Another performance benefit lies in the housing’s structural strength. The rigid SS316L construction supports defined pressure ratings and minimizes deformation, even when handling high flow rates or viscous liquids. This stability contributes to consistent filtration efficiency and predictable system behavior.

Compared with lower-grade materials, a SS316L Bag Filter Housing with EPDM Gasket helps reduce maintenance-related interruptions caused by corrosion, material fatigue, or sealing failure.

Application Scenarios Across Industrial Processes

A SS316L Bag Filter Housing with EPDM Gasket is widely used in industrial applications where liquid cleanliness and system safety are essential.

In water treatment and process water systems, the housing supports the removal of sediment, rust, and particulate contaminants before downstream treatment stages. The corrosion resistance of SS316L allows the housing to perform reliably under varying water chemistries.

In chemical processing operations, the SS316L Bag Filter Housing with EPDM Gasket is applied to filter intermediate products, solvents, and process fluids. The combination of stainless steel and EPDM sealing supports stable operation when exposed to controlled chemical conditions.

The housing is also suitable for food, beverage, and pharmaceutical support processes, where hygienic design, smooth internal surfaces, and dependable sealing are required for routine cleaning and inspection.

Operational Efficiency and Maintenance Considerations

Ease of maintenance is an important factor in industrial filtration system design. A SS316L Bag Filter Housing with EPDM Gasket typically features a top-opening cover that allows quick access to the filter bag, reducing downtime during routine replacement.

The internal basket supports the filter bag evenly, promoting uniform flow distribution and helping extend filter bag service life. During maintenance, the EPDM Gasket can be inspected and reused if it remains in good condition, supporting cost-effective operation.

Additionally, the smooth surface finish of SS316L stainless steel simplifies cleaning procedures, which is especially beneficial in applications with frequent product changeovers.

Sealing Performance and Process Safety

Sealing reliability is a critical requirement for pressure filtration systems. The EPDM Gasket used in a SS316L Bag Filter Housing with EPDM Gasket provides consistent compression and elasticity, helping maintain a secure seal even after repeated opening and closing cycles.

This sealing performance reduces the risk of leaks that could compromise product quality or workplace safety. In industrial environments where containment is essential, the gasket material supports controlled operation and minimizes the likelihood of unintended fluid release.

Proper gasket selection and installation ensure that the SS316L Bag Filter Housing with EPDM Gasket operates as a dependable filtration component within the overall system.

Long-Term Economic Value

From a lifecycle perspective, a SS316L Bag Filter Housing with EPDM Gasket offers strong long-term value. Although stainless steel housings typically represent a higher initial investment, their resistance to corrosion and extended service life reduce replacement frequency.

The durability of the EPDM Gasket further supports cost efficiency by minimizing sealing-related maintenance and downtime. Over time, these factors contribute to lower total operating costs and improved system reliability.

For facilities seeking stable filtration performance with predictable maintenance requirements, this housing configuration provides a practical balance between performance and cost control.

Manufacturing Quality and Customization Options

A high-quality SS316L Bag Filter Housing with EPDM Gasket is produced under controlled fabrication and inspection processes to ensure dimensional accuracy, weld integrity, and surface finish consistency. These factors directly influence pressure resistance and sealing performance.

Customization options may include housing size, bag configuration, inlet and outlet connections, and surface treatment. Gasket materials can also be selected or adjusted based on specific temperature ranges or fluid compatibility requirements, with EPDM being a commonly specified option.

Such flexibility allows the SS316L Bag Filter Housing with EPDM Gasket to be integrated seamlessly into a wide range of industrial filtration systems.

Closing Perspective

For industrial operations that require dependable liquid filtration combined with secure sealing, the SS316L Bag Filter Housing with EPDM Gasket provides a stable and well-balanced solution. Its corrosion-resistant construction, reliable gasket performance, and practical maintenance design support consistent operation across diverse industrial applications.

By focusing on material integrity and sealing reliability, this housing configuration helps filtration systems operate efficiently and predictably over the long term.