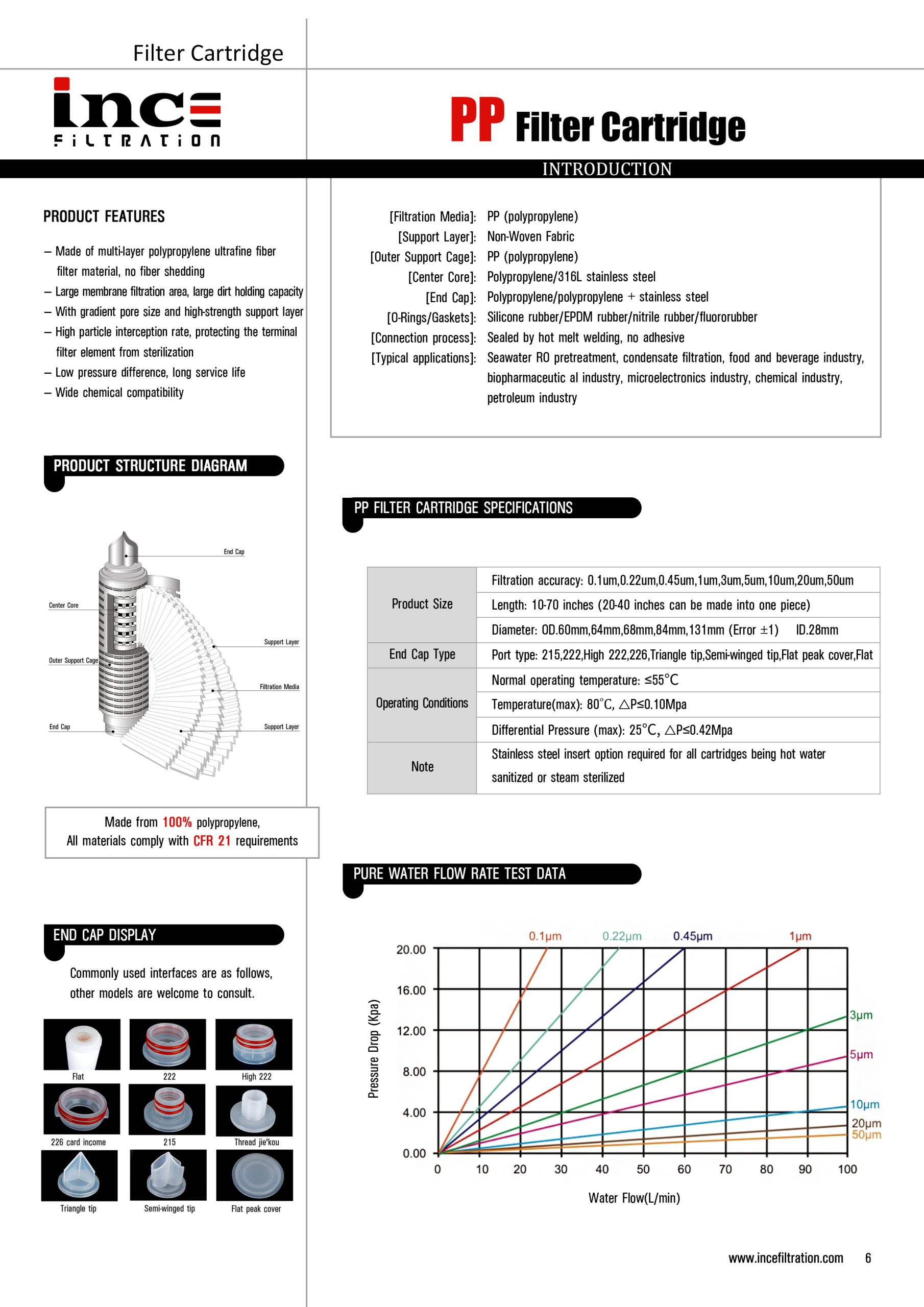

PP Pleated Filter Cartridges Description

PP pleated filter cartridge is made of ultra-fine PP fiber membrane and non-woven fabric or woven nets, inner and outer support layers by pleating.The cage, core and end cap are fabricated by thermal bond technology. It contains no adhesive, no leakage and no secondary pollution.The pleated design offers a large membrane filter area, high dirt olding capability, low differential pressure and long service life. The whole filter cartridge is made of 100% pure PP to offer a wide range of chemical compatibility.

Why Choose Ince’s PP Pleated Filter Cartridge

Choosing Ince’s PP Pleated Filter Cartridge comes with several key advantages that make it an excellent choice for various filtration applications. Below are some reasons why Ince’s PP Pleated Filter Cartridge stands out:

- 1. Superior Filtration Efficiency

Ince’s PP Pleated Filter Cartridges are designed to provide high filtration efficiency, effectively removing particulates, sediments, and contaminants from liquids. The pleated design increases the surface area, allowing for better dirt holding capacity and longer service life.

- 2. High-Quality Polypropylene Material

The filter cartridges are made from high-quality polypropylene (PP), a material known for its excellent chemical resistance and durability. This makes the cartridges suitable for filtering a wide range of fluids, including chemicals, water, and other process fluids, without compromising performance.

- 3. Broad Chemical Compatibility

Thanks to the use of 100% polypropylene, Ince’s PP Pleated Filter Cartridges are compatible with a wide range of chemicals and solvents. This broad chemical compatibility ensures that the cartridges can be used in diverse industrial applications, including food and beverage, pharmaceuticals, and water treatment.

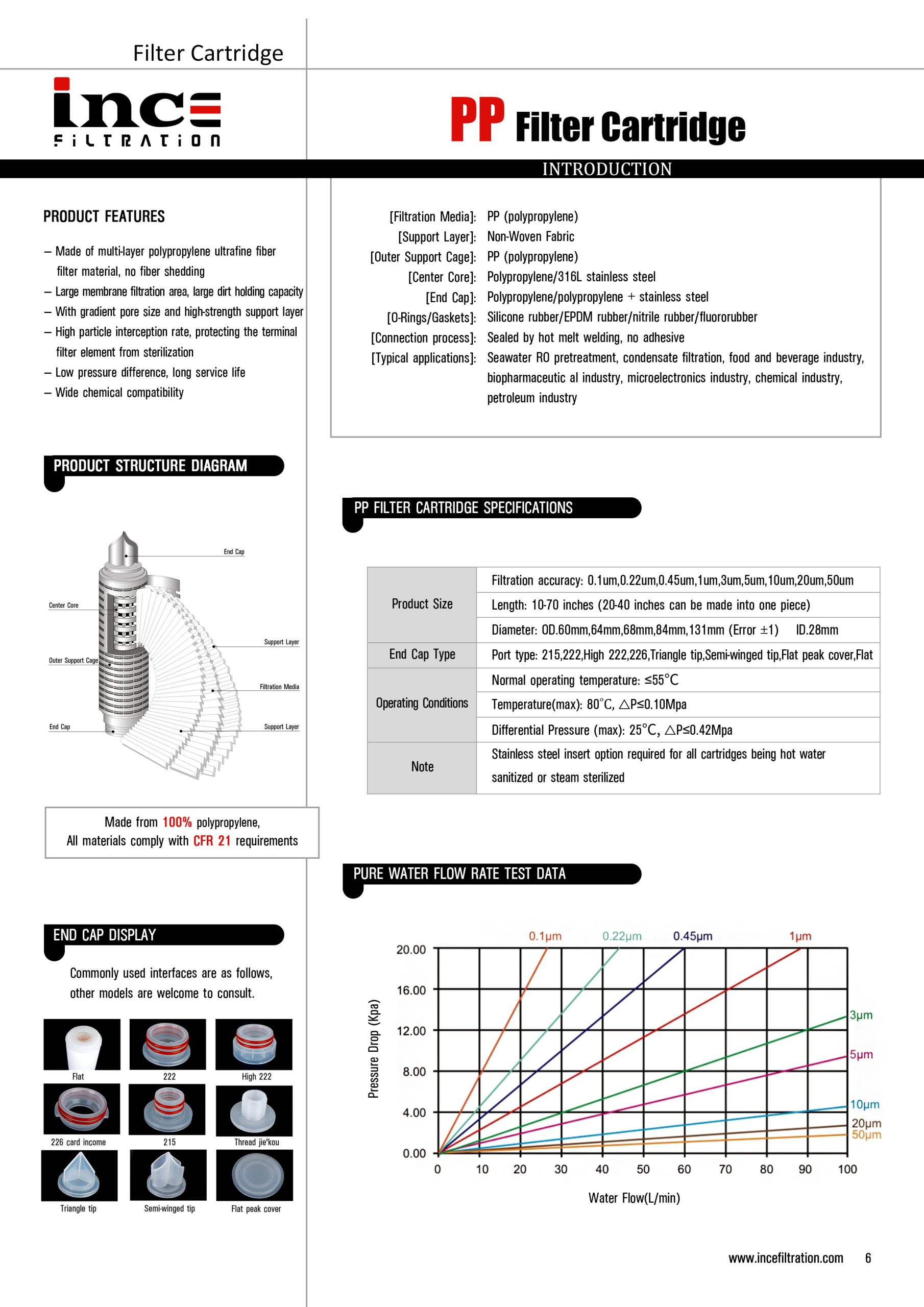

- 4. Wide Range of Micron Ratings

Ince offers PP Pleated Filter Cartridges in a variety of micron ratings, from 0.1 to 50 microns. This range allows users to choose the appropriate filtration level for their specific application, ensuring optimal performance whether the requirement is for fine or coarse filtration.

- 5. High Flow Rates and Low Pressure Drop

The pleated design of the cartridge not only increases the surface area but also ensures high flow rates with minimal pressure drop. This feature is particularly beneficial in high-volume filtration systems where maintaining a steady flow is crucial.

- 6. FDA Compliance and Safety

Ince’s PP Pleated Filter Cartridges are manufactured under strict quality control standards and are compliant with FDA regulations. This ensures that they are safe for use in food and beverage applications, as well as in other industries where product safety is paramount.

- 7. Cost-Effective Filtration Solution

These cartridges offer a cost-effective solution for various filtration needs. Their long service life and high dirt holding capacity reduce the need for frequent replacements, leading to lower operating costs and reduced downtime.

- 8. Versatility in Applications

Ince’s PP Pleated Filter Cartridges are versatile and can be used in multiple industries, including water treatment, chemical processing, electronics, pharmaceuticals, and food and beverage. Their ability to handle different fluids and contaminants makes them a go-to solution for many filtration challenges.

- 9. Customizable Options

Ince provides customizable options for their PP Pleated Filter Cartridges, including different sizes, micron ratings, and configurations. This customization ensures that the filters can meet the specific needs of different applications, offering maximum flexibility to the user.

- 10. Reliable Performance

With a reputation for quality and reliability, Ince’s PP Pleated Filter Cartridges are trusted by professionals across various industries. Their consistent performance and durability ensure that your filtration systems operate efficiently and effectively, minimizing risks and maximizing productivity.

PP Pleated Filter Cartridge Details

- Hot Melt Spinning Process

External transmission and internal density, good pollution interception effect and long service life

- All interfaces use ultrasonic welding.

Customized composite membrane materials

are specially added.The interception efficiency can reach 98%.

- Customized On Demand

Various types of non-standard filter elements can be customized according to different needs of customers.

PP Pleated Filter Cartridge Features:

PP Pleated Filter Cartridge Applications:

-

1. Water Treatment

- Municipal Water Filtration: Used for pre-filtration and final filtration to ensure clean and safe drinking water.

- Industrial Water Treatment: Removes particulates and sediments from process water in industrial plants.

- Wastewater Treatment: Assists in filtering out contaminants from wastewater before discharge or reuse.

2. Food and Beverage Industry

- Beverage Filtration: Ensures the purity of products like bottled water, juices, and soft drinks by removing sediments, bacteria, and other contaminants.

- Dairy and Dairy Products: Used in milk and dairy product processing to remove impurities and ensure product quality.

- Edible Oils and Vinegar: Filters out particulates and ensures clarity in edible oils, vinegar, and other liquid food products.

3. Pharmaceuticals and Biotechnology

- Pharmaceutical Manufacturing: Used in the production of injectable drugs, vaccines, and other pharmaceuticals to maintain sterility and product purity.

- Bioprocessing: Ensures the removal of contaminants during the filtration of culture media, buffers, and other bioprocessing fluids.

- Laboratory Filtration: Utilized in research labs for filtering chemicals, reagents, and other lab-grade solutions.

4. Chemical Processing

- Acids and Bases Filtration: Suitable for filtering corrosive chemicals, acids, and bases used in industrial processes.

- Solvent Filtration: Ensures the removal of particulates and impurities from various solvents.

- Electronics Manufacturing: Provides filtration in the production of high-purity chemicals and solvents used in electronics manufacturing.

5. Oil and Gas Industry

- Petroleum Refining: Removes contaminants from lubricants, fuels, and other petrochemical products.

- Natural Gas Filtration: Ensures the purity of natural gas by removing particulates and moisture.

- Hydraulic Fluids: Filters out contaminants in hydraulic systems to prevent equipment wear and maintain system efficiency.

6. Cosmetics and Personal Care

- Lotions and Creams: Used in the production of lotions, creams, and other personal care products to ensure product purity and consistency.

- Fragrances: Filters out impurities in perfumes and other fragrance products to maintain quality.

- Hair Care Products: Ensures the purity of shampoos, conditioners, and other hair care products by removing contaminants.

7. Electronics and Semiconductor Industry

- Microelectronics Manufacturing: Provides high-purity filtration for the production of semiconductors, printed circuit boards, and other electronic components.

- LCD and LED Display Production: Ensures that the chemicals and solvents used in the production of displays are free of contaminants.

- Photovoltaic (Solar) Panel Manufacturing: Removes particulates and impurities from the chemicals used in solar panel production.

8. Automotive Industry

- Paint and Coatings Filtration: Ensures the purity of paints and coatings used in automotive manufacturing, preventing defects and ensuring a smooth finish.

- Lubricants and Coolants: Filters out impurities in lubricants and coolants to maintain engine and machinery performance.

- Fuel Filtration: Used in the pre-filtration and final filtration of fuels to ensure the removal of particulates and water.

9. Healthcare and Medical Devices

- Sterile Filtration: Ensures the sterility of medical devices and fluids used in healthcare settings.

- Dialysis Water Treatment: Used in the filtration of water used in dialysis to remove contaminants and ensure patient safety.

- IV Solutions: Filters impurities from intravenous solutions, ensuring they meet stringent purity standards.

10. Pulp and Paper Industry

- Process Water Filtration: Removes particulates from process water used in paper manufacturing to maintain product quality.

- Chemical Additives Filtration: Filters out impurities from chemicals and additives used in paper production.

- Final Product Filtration: Ensures the removal of any remaining particulates from paper products before they reach the market.

11. Power Generation

- Boiler Feed Water Filtration: Removes particulates and dissolved solids from feed water to prevent scaling and corrosion in boilers.

- Cooling Tower Water Filtration: Ensures the cleanliness of cooling tower water, reducing the risk of fouling and extending the life of equipment.

- Turbine Oil Filtration: Filters contaminants from turbine oils to maintain efficient operation and extend the lifespan of turbines.

12. Industrial Manufacturing

- Process Fluid Filtration: Ensures the purity of process fluids used in various manufacturing operations, such as metalworking and chemical production.

- Final Product Filtration: Removes contaminants from final products to ensure they meet quality standards.

- Cooling and Heating Systems: Filters out particulates from the fluids used in industrial cooling and heating systems to maintain efficiency and prevent equipment damage.

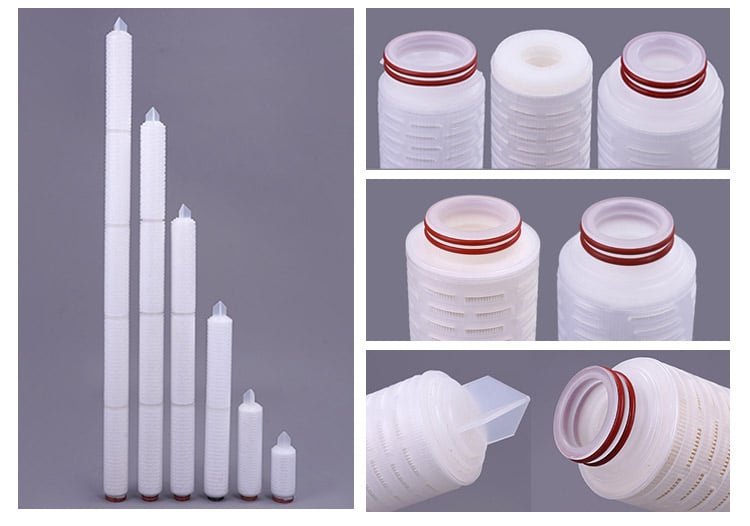

End Caps of PP Pleated Membrane Filter Cartridges:

Search: Select from the options below to search our selection of PP Pleated Filter Cartridge. For questions or custom orders please Contact Us.