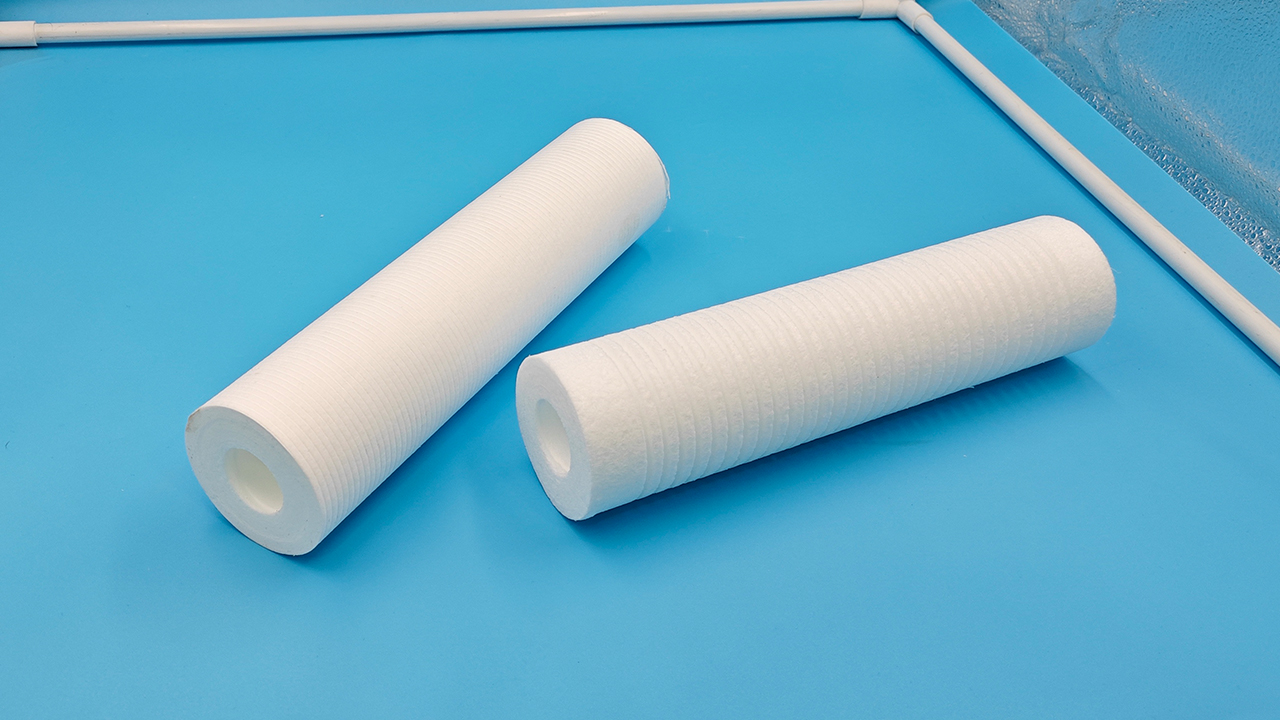

PP Melt Blown Filters Built for Versatile Liquid Filtration Applications

# PP Melt Blown Filters Built for Versatile Liquid Filtration Applications

Exceptional Filtration Efficiency

PP melt blown filters are engineered to provide outstanding filtration efficiency, making them ideal for various liquid filtration applications. These filters utilize a unique manufacturing process that creates a dense yet porous structure, allowing them to capture particles with precision. Whether you’re dealing with water purification, chemical processing, or food and beverage filtration, these filters can effectively remove contaminants, ensuring the purity of your liquids.

With their superior particle retention capabilities, PP melt blown filters can achieve high dirt-holding capacity while maintaining low pressure drop. This results in longer filter life and reduced maintenance costs, making them a cost-effective solution for industries requiring reliable filtration.

Versatile Applications Across Industries

The versatility of PP melt blown filters makes them suitable for a wide range of applications across different industries. In the pharmaceutical and biotech sectors, these filters ensure that sterile solutions remain uncontaminated during production and packaging. Furthermore, they are used extensively in the food and beverage industry to maintain product quality and safety by removing unwanted particulates.

Additionally, in industrial applications, PP melt blown filters serve as pre-filters for larger systems, effectively extending the life of downstream equipment. Their adaptability allows businesses to customize filtration solutions that meet their specific needs, thereby enhancing operational efficiency.

Environmentally Friendly Choice

Choosing PP melt blown filters is not only beneficial for your filtration needs but also for the environment. Made from polypropylene, these filters are inherently resistant to chemical degradation, ensuring durability and longevity. They are also recyclable, which contributes to reducing waste and promoting sustainability in manufacturing processes.

By opting for these filters, companies can meet their environmental responsibilities while maintaining high standards of liquid filtration. Investing in PP melt blown filters demonstrates a commitment to both product quality and ecological preservation, aligning your business with modern sustainability practices.

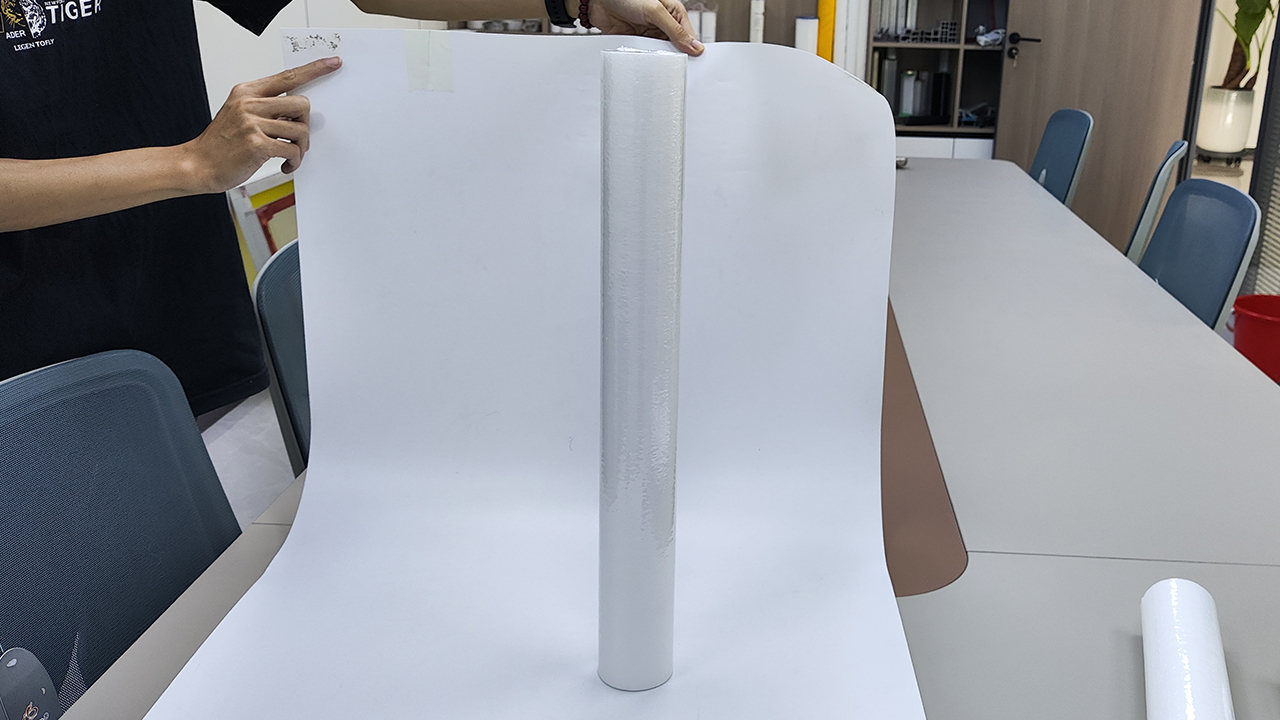

Easy Installation and Maintenance

Another advantage of PP melt blown filters is their user-friendly design, which allows for quick installation and minimal maintenance. These filters come in various sizes and configurations, making it easy to find the right fit for any system. The straightforward replacement process minimizes downtime, ensuring that operations continue smoothly without interruptions.

Moreover, regular maintenance is simplified as the filters do not require extensive cleaning procedures. Their efficiency in capturing particles means less frequent replacements, allowing businesses to focus on their core operations rather than on filtration management.

Cost-Effective Filtration Solutions

In today’s competitive market, cost-effectiveness is a critical factor for businesses looking to optimize their operations. PP melt blown filters offer an economical filtration solution that does not compromise on quality. Their durability and high dirt-holding capacity translate into lower operational costs over time, making them a smart investment for companies of all sizes.

By integrating PP melt blown filters into your liquid filtration processes, you can achieve significant savings while ensuring compliance with industry standards. This balance of performance and affordability makes them an attractive option for any organization seeking reliable filtration solutions.