PP Liquid Filter Bags for Food, Beverage, and Pharmaceutical Use

A PP Liquid Filter Bag is commonly applied in food, beverage, and pharmaceutical processes where hygiene standards, material compatibility, and filtration stability are critical. In these industries, liquid filtration is not only about particle removal but also about protecting downstream processes and maintaining consistent product quality. Polypropylene-based filter bags offer a practical balance between performance reliability and operational efficiency in regulated production environments.

Material Characteristics and Process Compatibility

A Polypropylene Liquid Filter Bag is valued for its chemical resistance, low fiber shedding, and suitability for contact with a wide range of process liquids. In food and beverage operations, an industrial liquid filter bag polypropylene construction helps remove particulates from water, syrups, oils, and intermediate liquids without introducing unwanted contaminants.

For pharmaceutical processing, material consistency is especially important. A PP liquid filter bag for pharmaceutical industry applications is often used in non-critical pre-filtration stages to protect finer downstream filtration or separation steps. Polypropylene maintains stable physical properties under varying temperatures and cleaning conditions, supporting predictable filtration behavior across production batches.

An Industrial PP Liquid Filter Bag designed with controlled manufacturing processes helps ensure dimensional stability and repeatable performance, which are essential for maintaining validated process conditions in regulated industries.

Construction Methods for Hygiene and Reliability

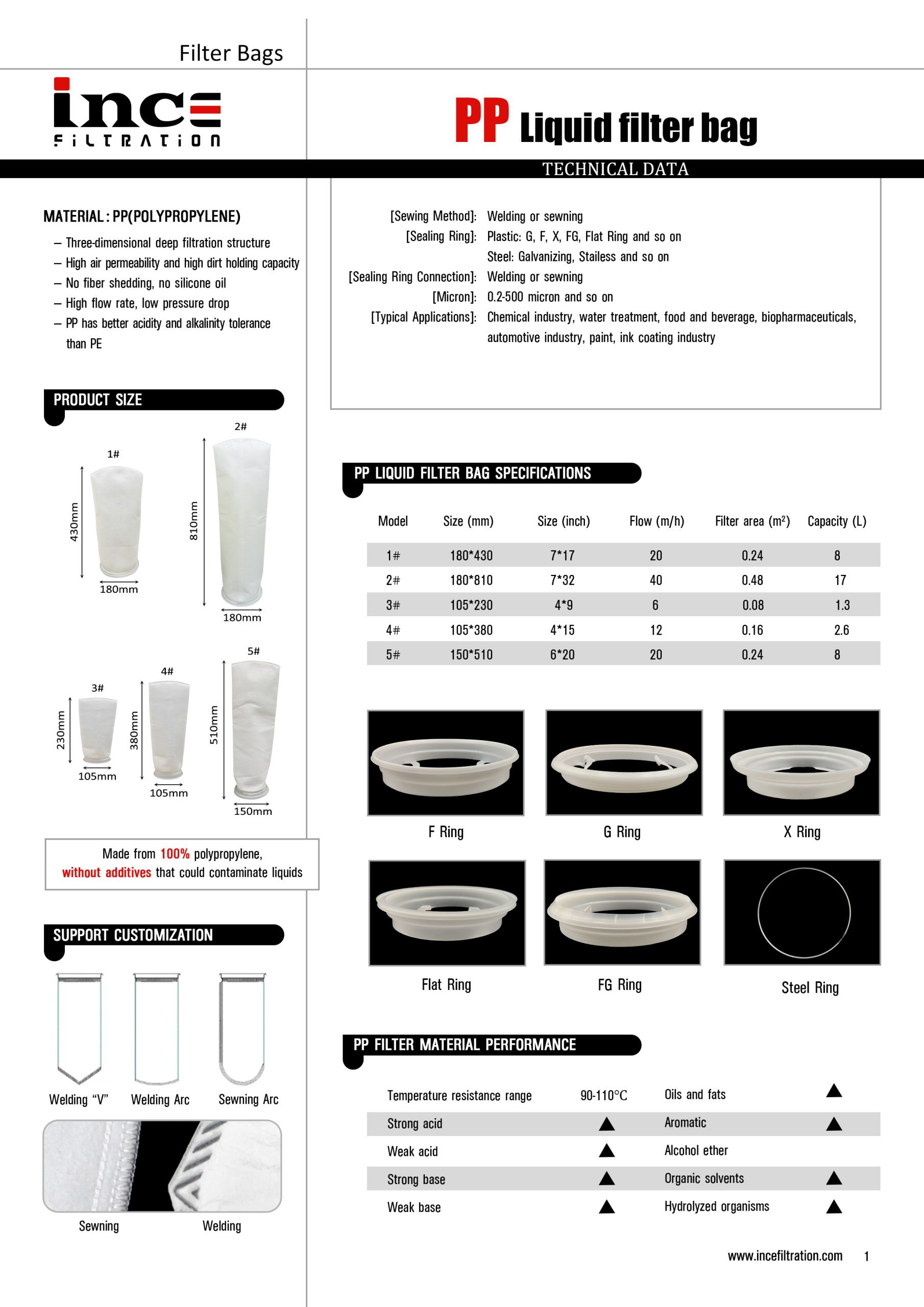

Construction method influences both cleanliness and mechanical strength. A welded PP liquid filter bag is produced through thermal bonding, creating smooth, uniform seams without needle holes. This design reduces the risk of bypass and fiber release, making it suitable for hygiene-sensitive applications in food, beverage, and pharmaceutical production.

A sewn PP liquid filter bag is also widely used where operating pressures and cleanliness requirements are moderate. When manufactured under controlled conditions, sewn designs provide reliable filtration performance and flexibility across a range of sizes and micron ratings. They are often selected for general process filtration where ease of replacement and cost control are priorities.

Choosing between welded and sewn construction depends on process sensitivity, operating conditions, and internal quality standards. Both options are available within Industrial PP Liquid Filter Bag product ranges to support different filtration needs.

Ring Options and Housing Integration

Proper sealing is essential to prevent unfiltered liquid from bypassing the media. A PP liquid filter bag with plastic ring is commonly used in food and beverage applications due to its corrosion resistance and lightweight handling. Plastic rings provide consistent sealing in standard housings while simplifying installation and removal during routine maintenance.

For systems operating under higher pressure or requiring frequent change-outs, a PP liquid filter bag with steel ring offers enhanced durability and dimensional stability. Steel rings maintain their shape over repeated use, supporting reliable sealing in demanding production environments.

Matching ring type to housing design ensures proper fit and reduces variability in filtration performance, which is especially important in processes where consistency and traceability are required.

Application-Specific Performance Considerations

A PP liquid filter bag for food and beverage use is typically applied to clarify liquids, protect downstream equipment, and support consistent product appearance. Depth-style filtration within the bag helps distribute contaminant loading evenly, reducing sudden pressure increases and extending service life.

In pharmaceutical operations, a PP liquid filter bag for pharmaceutical industry processes supports stable upstream filtration. By removing particulate matter early in the process, it helps protect critical filtration stages and contributes to overall system reliability. Consistent bag performance simplifies maintenance planning and supports controlled production schedules.

Across both sectors, selecting an appropriate micron rating and bag configuration allows filtration systems to be tailored to specific process requirements without unnecessary over-filtration.

Supply Reliability and Replacement Planning

Effective PP liquid filter bag replacement planning is essential for maintaining uninterrupted production. Establishing replacement intervals based on pressure drop and process conditions helps avoid unplanned shutdowns while ensuring consistent filtration quality.

Working with a dependable PP liquid filter bag supplier supports this consistency. A reliable supplier provides uniform dimensions, stable material quality, and repeatable construction methods across production batches. This consistency is especially valuable for facilities operating multiple filtration systems or standardized production lines.

Choosing an experienced PP Liquid Filter Bag Manufacturer enables long-term supply stability and supports compliance with internal quality requirements. By aligning material properties, construction methods, and sealing options with process needs, PP Liquid Filter Bags become a dependable component in food, beverage, and pharmaceutical liquid filtration systems.