PP Liquid Filter Bags Designed for Industrial Liquid Filtration

Industrial liquid filtration systems rely on stable, chemically compatible, and cost-efficient filtration media to maintain process quality and operational continuity. The PP Liquid Filter Bag has become a widely adopted solution across manufacturing sectors due to its balanced performance, material reliability, and adaptability to different filtration stages. From pre-filtration to fine polishing, polypropylene-based filter bags support consistent contaminant removal while meeting the practical demands of industrial operations.

The Role of PP Liquid Filter Bag in Industrial Filtration

A PP Liquid Filter Bag is engineered to capture solid particles, gels, and process residues from liquids such as water, chemicals, coatings, oils, and process fluids. Its depth filtration structure allows contaminants to be trapped throughout the media rather than only on the surface, helping to stabilize flow rates and extend service life.

In industrial environments where uptime and repeatability are critical, the PP Liquid Filter Bag offers predictable filtration efficiency and mechanical strength. This makes it suitable for continuous production lines as well as batch-based processes that require reliable and repeatable filtration outcomes.

Advantages of Polypropylene as Filter Media

A Polypropylene Liquid Filter Bag is valued for its chemical resistance and thermal stability. Polypropylene fibers withstand exposure to acids, alkalis, and many organic solvents without degrading or releasing unwanted extractables into the process fluid. This property is essential in applications where fluid purity directly impacts product performance.

In addition, polypropylene exhibits low moisture absorption, allowing the filter bag to maintain consistent dimensions and filtration accuracy during operation. These characteristics make industrial liquid filter bag polypropylene products suitable for demanding applications where material stability cannot be compromised.

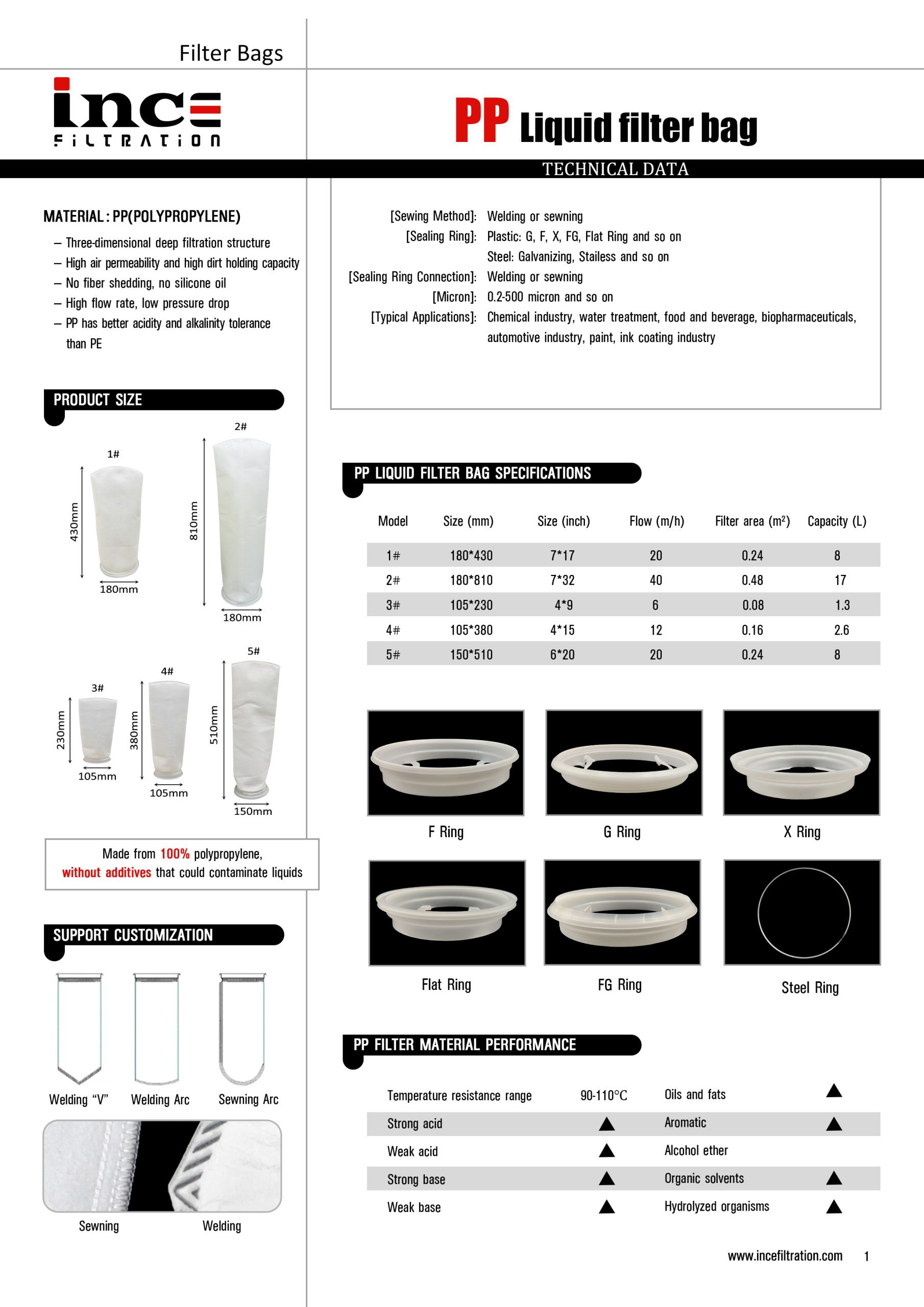

Construction Options: Welded and Sewn Designs

The construction method of a PP Liquid Filter Bag directly affects filtration integrity and application suitability.

A welded PP liquid filter bag is manufactured using thermal bonding technology, creating sealed seams without needle holes. This construction reduces the risk of bypass and fiber shedding, making welded designs ideal for fine filtration stages and sensitive applications where particle control is critical.

A sewn PP liquid filter bag uses industrial stitching methods to assemble the filter media. Sewn designs are widely used in general industrial filtration due to their flexibility, cost efficiency, and availability in a wide range of sizes and micron ratings. When produced under controlled quality standards, sewn bags deliver consistent and reliable performance in medium-duty filtration environments.

Ring Types and Sealing Performance

Proper sealing between the filter bag and housing is essential to ensure all process liquid passes through the filter media. A PP liquid filter bag with plastic ring is commonly used in standard filtration systems where corrosion resistance and ease of installation are priorities. Plastic rings are lightweight and compatible with many housing designs, supporting efficient maintenance routines.

For higher pressure systems or applications with frequent bag changes, a PP liquid filter bag with steel ring offers enhanced mechanical strength and dimensional stability. Steel rings help maintain a secure seal under fluctuating operating conditions, reducing the risk of leakage and unfiltered bypass.

Industrial Applications and Process Compatibility

An Industrial PP Liquid Filter Bag is used across multiple sectors, including chemical processing, surface treatment, food-related non-contact processes, coatings, inks, wastewater treatment, and electronics manufacturing. In each of these applications, the filter bag plays a key role in protecting downstream equipment and ensuring final product consistency.

The adaptability of industrial liquid filter bag polypropylene solutions allows them to be deployed at different filtration stages. Coarser micron ratings are often selected for pre-filtration to remove larger particles, while finer grades are used for final polishing to achieve tighter cleanliness standards.

Supply Reliability and Manufacturer Expertise

Working with an experienced PP Liquid Filter Bag Manufacturer is essential for maintaining consistent filtration performance over time. Manufacturing control over raw materials, fiber formation, and assembly methods ensures that each filter bag meets defined specifications for micron rating, strength, and compatibility.

A dependable PP liquid filter bag supplier supports stable production planning by offering consistent quality, standardized dimensions, and responsive technical support. For industrial users managing large-scale filtration systems, supplier reliability directly influences maintenance scheduling and operating costs.

Replacement Strategy and Operational Efficiency

Regular PP liquid filter bag replacement is a critical aspect of filtration system management. As contaminants accumulate, pressure differential increases and flow rates decline. Replacing the filter bag at the appropriate interval helps maintain system efficiency, protect equipment, and prevent unexpected production interruptions.

Establishing a structured replacement strategy based on operating conditions and process fluid characteristics allows industrial users to optimize filter usage without compromising performance. High-quality PP Liquid Filter Bag designs contribute to predictable service life and simplified maintenance procedures.

Conclusion

The PP Liquid Filter Bag remains a practical and effective solution for industrial liquid filtration applications that demand reliability, material compatibility, and operational flexibility. Through careful selection of construction type, ring design, and supplier partnership, industrial users can tailor filtration systems to meet specific process requirements. As production standards continue to rise, polypropylene-based filter bags will remain a foundational component in efficient and dependable industrial filtration systems.