PP Liquid Filter Bag Options for Fine and Coarse Filtration

In many industrial liquid processing systems, filtration requirements vary significantly depending on particle size, fluid characteristics, and process stability expectations. As production conditions become more demanding, users often face challenges such as inconsistent filtration results, frequent bag changes, and compatibility issues with existing housings. The PP Liquid Filter Bag is widely adopted as a flexible and reliable solution, offering both fine and coarse filtration options while maintaining stable performance across diverse operating environments.

Product Design for Flexible Filtration Requirements

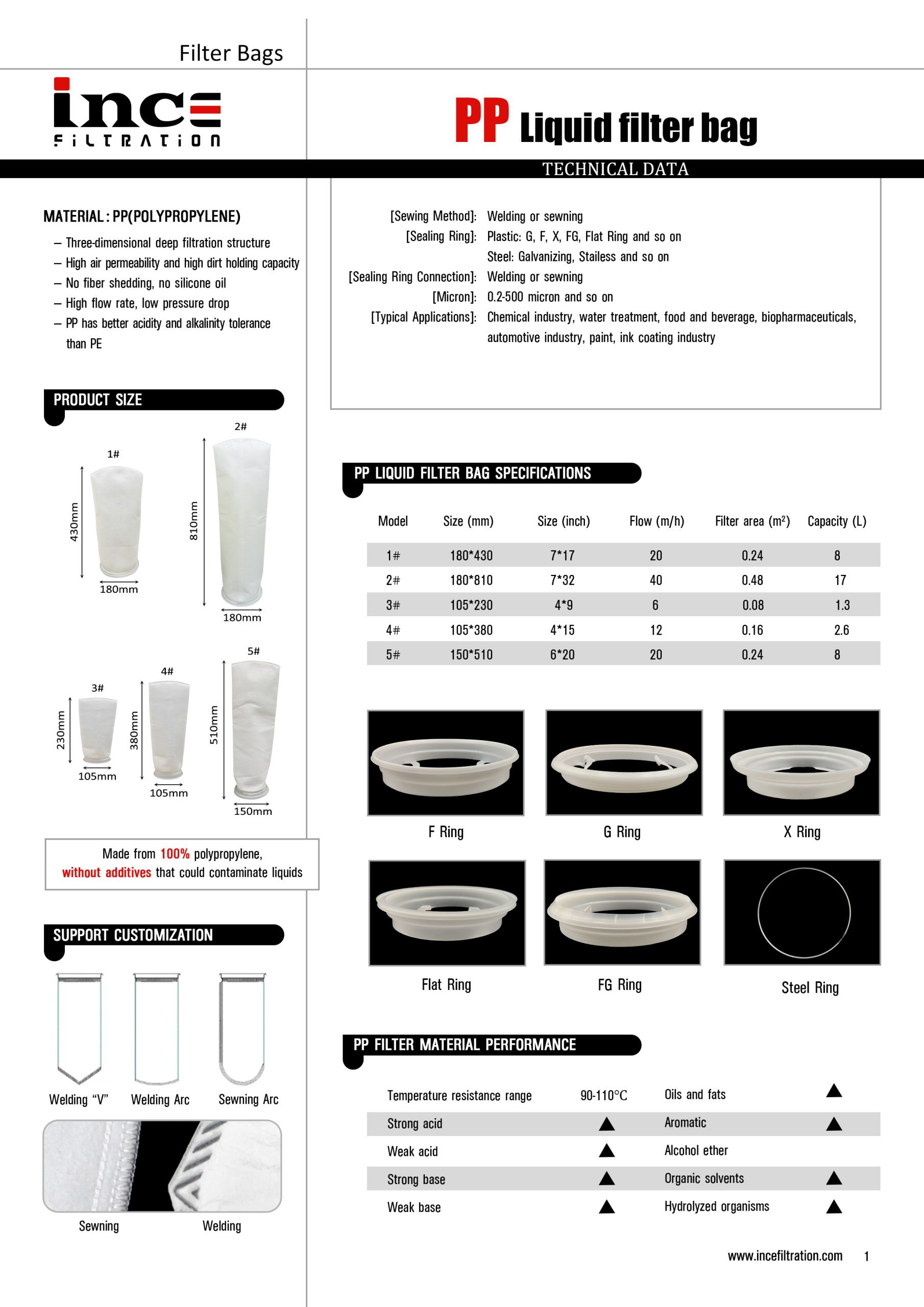

The PP Liquid Filter Bag is engineered using polypropylene media designed to handle a wide range of particle retention needs. From coarse pre-filtration to fine polishing stages, this product structure allows users to adapt filtration performance without modifying the overall system design. The Polypropylene Liquid Filter Bag combines controlled pore distribution with consistent material density to support predictable filtration behavior.

For demanding industrial environments, the Industrial PP Liquid Filter Bag is manufactured to withstand continuous operation, chemical exposure, and pressure fluctuations. Its design supports use in standard bag filter housings, making it suitable for multiple filtration systems across water treatment, chemical processing, and general industrial fluid handling.

Construction Options and Sealing Configurations

Different production processes require different assembly methods, and the PP Liquid Filter Bag is available in both welded and sewn constructions. A welded PP liquid filter bag provides enhanced structural integrity and reduced risk of fiber migration, making it suitable for applications where product purity is critical. In contrast, a sewn PP liquid filter bag offers flexibility and cost efficiency for less demanding filtration tasks.

Sealing configurations also play a crucial role in filtration efficiency. Options such as a PP liquid filter bag with plastic ring or a PP liquid filter bag with steel ring ensure secure installation and reliable sealing within the filter housing. These configurations help minimize bypass and maintain stable flow rates under varying operating pressures.

Performance Advantages in Fine and Coarse Filtration

One key advantage of the PP Liquid Filter Bag lies in its adaptability across filtration grades. Fine filtration applications benefit from consistent particle retention and low fiber shedding, while coarse filtration stages achieve effective removal of larger contaminants without excessive pressure drop. This balance allows users to optimize system performance at different stages of the process.

Compared with rigid filter elements, industrial liquid filter bag polypropylene solutions offer higher dirt-holding capacity and simplified maintenance. This results in longer service intervals and reduced operational downtime, particularly in systems where contaminant loads fluctuate during operation.

Application Suitability Across Industrial Processes

The versatility of the PP Liquid Filter Bag makes it suitable for a broad range of industrial applications. It is commonly used in water treatment, surface finishing, chemical manufacturing, and process fluid protection, where both fine and coarse filtration stages are required within the same system. The availability of multiple micron ratings supports precise process control without extensive system redesign.

From a procurement perspective, working with an experienced PP Liquid Filter Bag Manufacturer ensures consistent product quality, dimensional accuracy, and material traceability. Reliable sourcing also simplifies inventory management and supports standardized PP liquid filter bag replacement schedules across multiple facilities.

Operational Value and Supply Considerations

Beyond filtration performance, the PP Liquid Filter Bag delivers measurable operational and economic value. Its lightweight construction and straightforward installation reduce labor requirements during maintenance, while high contaminant capacity lowers overall replacement frequency. These factors contribute to improved system uptime and predictable operating costs.

Selecting a dependable PP liquid filter bag supplier allows users to align filtration solutions with long-term process requirements. With multiple construction options, sealing designs, and filtration grades available, the Polypropylene Liquid Filter Bag provides a scalable solution for operations seeking reliable filtration performance across both fine and coarse applications.