PP Filter Cartridge Designed for Stable Filtration and Reliable Process Support

In many industrial liquid filtration processes, maintaining consistent fluid quality is essential for both product integrity and equipment protection. Filtration components are expected to operate under continuous flow conditions while delivering predictable retention performance. As operating environments become more demanding, users increasingly require filtration solutions that balance efficiency, durability, and compatibility with existing systems.

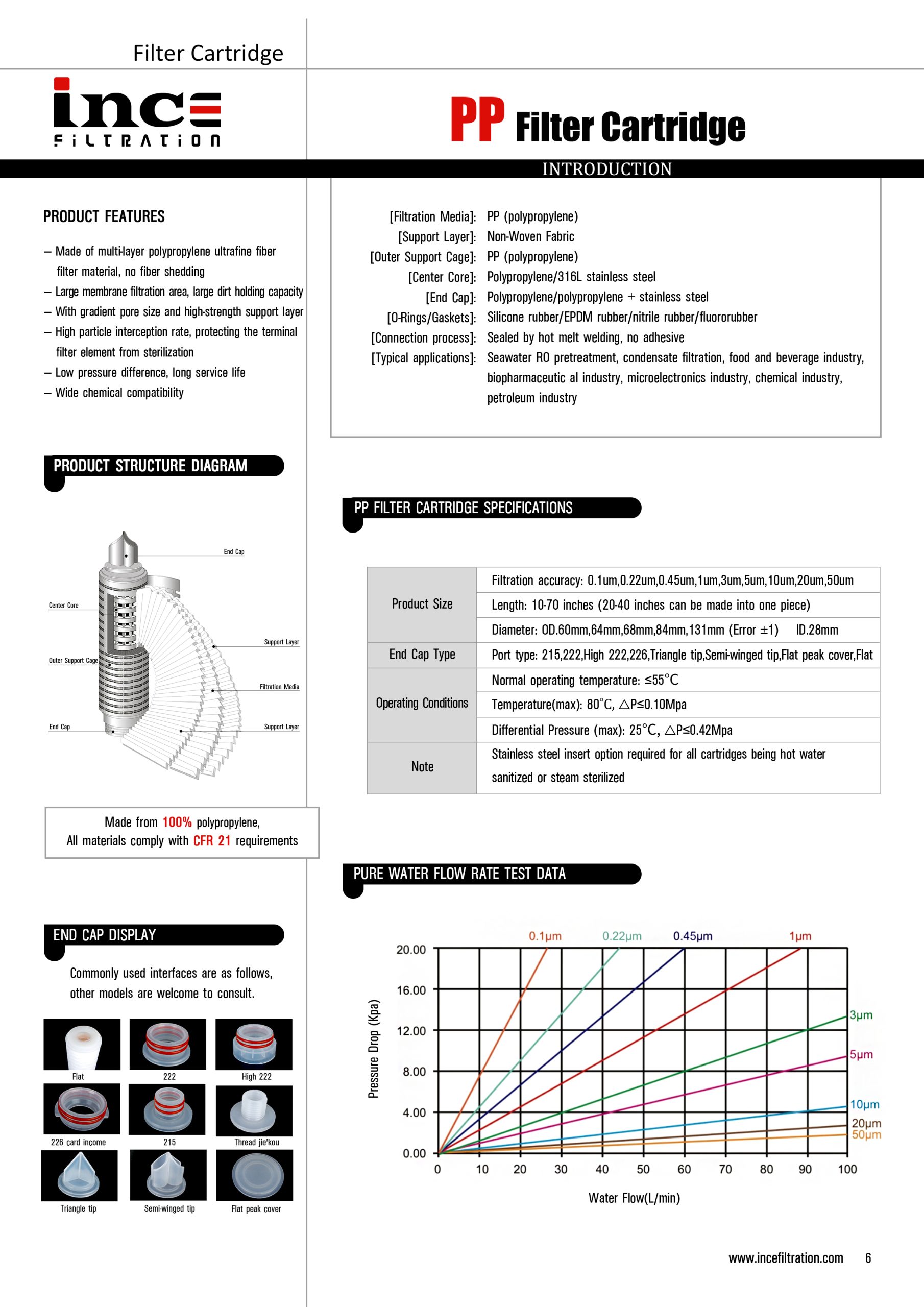

The pp filter cartridge has become a widely adopted solution for applications that require reliable particulate removal without complex system modifications. By combining a cartridge-based structure with support non-woven fabric, this type of cartridge offers stable filtration performance while meeting the practical needs of industrial users focused on long-term operation and cost control.

Product Design Built Around Cartridge Filtration Principles

The cartridge structure of a pp filter cartridge is designed to provide controlled filtration within a compact and standardized form factor. Unlike loose media or disposable sheet filters, the cartridge format allows for precise installation inside filter housings, ensuring consistent sealing and uniform flow distribution. This structural consistency is critical for maintaining stable filtration efficiency across repeated operating cycles.

At the core of the cartridge design is the use of support non-woven fabric, which forms the primary filtration layer. This fabric structure enables effective particle retention while maintaining adequate permeability for fluid flow. The non-woven construction creates a depth filtration effect, allowing contaminants to be captured throughout the media thickness rather than only on the surface, which helps extend service life.

The pp filter cartridge design also emphasizes material uniformity and structural stability. Polypropylene is selected for its chemical resistance and mechanical reliability, allowing the cartridge to perform consistently in contact with a wide range of liquids. The integration of cartridge geometry with support non-woven fabric results in a filtration element that aligns well with industrial filtration standards.

Filtration Performance and Operational Stability

One of the key advantages of a well-designed pp filter cartridge lies in its ability to maintain consistent filtration performance under variable operating conditions. The support non-woven fabric provides uniform pore distribution, which helps control particle retention without causing sudden pressure fluctuations. This stability is essential for processes that rely on steady flow rates and predictable filtration outcomes.

Compared with conventional filtration media, cartridge-based filtration offers improved flow management. The structured cartridge format ensures that liquids pass evenly through the filtration media, reducing localized clogging and uneven loading. As a result, the cartridge delivers more consistent pressure behavior throughout its service life, supporting stable system operation.

In addition, the combination of polypropylene material and support non-woven fabric contributes to dependable filtration efficiency over time. The cartridge resists deformation under normal operating pressures, ensuring that filtration performance remains stable from installation through replacement. This reliability makes the pp filter cartridge suitable for continuous or batch processes where filtration consistency directly affects downstream operations.

Application Suitability Across Industrial Processes

The pp filter cartridge is widely used in industrial applications where fluid cleanliness and system protection are critical. In water treatment processes, the cartridge helps remove suspended solids before liquids enter sensitive equipment or downstream treatment stages. Its cartridge design allows for easy integration into standard housings commonly used in industrial water systems.

Chemical processing environments also benefit from the material compatibility of polypropylene cartridges. The chemical resistance of the pp filter cartridge enables it to handle a broad range of process fluids without compromising structural integrity. The support non-woven fabric ensures stable filtration even when fluids contain variable particle loads, supporting reliable operation in dynamic process conditions.

In manufacturing and general industrial applications, cartridge filtration is often selected for its practicality and scalability. The standardized cartridge format allows users to adjust filtration capacity by changing cartridge size or quantity without redesigning the entire system. This flexibility makes the pp filter cartridge a practical choice for facilities that require adaptable filtration solutions.

Operational and Economic Value in Long-Term Use

From an operational perspective, the cartridge-based design simplifies installation and replacement procedures. The pp filter cartridge can be installed quickly within compatible housings, reducing downtime during maintenance intervals. This ease of handling supports efficient maintenance planning and minimizes disruption to production schedules.

The use of support non-woven fabric also contributes to economic value by extending the usable life of the cartridge. Depth filtration allows contaminants to be distributed throughout the media, delaying clogging and reducing replacement frequency. Over time, this characteristic helps lower consumable costs while maintaining consistent filtration performance.

In addition, the durability of polypropylene supports long-term cost efficiency. The cartridge maintains its structure under typical operating conditions, reducing the risk of premature failure. For operations focused on balancing performance with operating expenses, the pp filter cartridge provides a filtration solution that supports both technical and economic objectives.

Quality Consistency and Manufacturing Control

Consistent filtration performance depends not only on design but also on manufacturing precision. The production of a reliable pp filter cartridge requires strict control over material selection, non-woven fabric structure, and cartridge assembly. Uniform fiber distribution within the support non-woven fabric ensures predictable filtration behavior across different production batches.

Manufacturing processes are designed to maintain dimensional accuracy so that each cartridge fits securely within standard housings. Proper bonding between the polypropylene structure and the filtration media prevents bypass and ensures that all fluid passes through the intended filtration path. This attention to detail supports stable performance in real-world operating conditions.

For users seeking dependable filtration components, quality consistency provides confidence in system reliability. A pp filter cartridge produced under controlled manufacturing conditions delivers repeatable performance, supporting long-term process stability and reducing uncertainty in filtration outcomes.

For operations that require controlled particulate removal, stable flow behavior, and dependable material compatibility, the pp filter cartridge offers a balanced filtration solution. Its cartridge structure, combined with support non-woven fabric, provides reliable performance across a wide range of industrial applications while supporting practical installation and long-term operational efficiency.