Polypropylene Liquid Filter Bags for Chemical and Water Treatment

A PP Liquid Filter Bag is widely used in industrial filtration systems where chemical compatibility, stable filtration efficiency, and operational reliability are required. In both chemical processing and water treatment, filtration performance directly affects product quality, equipment protection, and overall system stability. Polypropylene material offers a balanced combination of chemical resistance and mechanical strength, making it a practical choice for demanding liquid filtration environments.

As filtration systems scale or operating conditions fluctuate, users increasingly rely on polypropylene filter bags to handle variable contaminant loads while maintaining predictable pressure behavior. For procurement teams and engineers, selecting an Industrial PP Liquid Filter Bag that aligns with system design and maintenance planning is essential for long-term operational efficiency.

Material Properties and Structural Advantages

Polypropylene is valued in liquid filtration for its broad chemical resistance and low extractables. An industrial liquid filter bag polypropylene construction can withstand exposure to acids, alkalis, and a wide range of process fluids commonly encountered in chemical and water treatment applications. This material stability supports consistent filtration performance without media degradation.

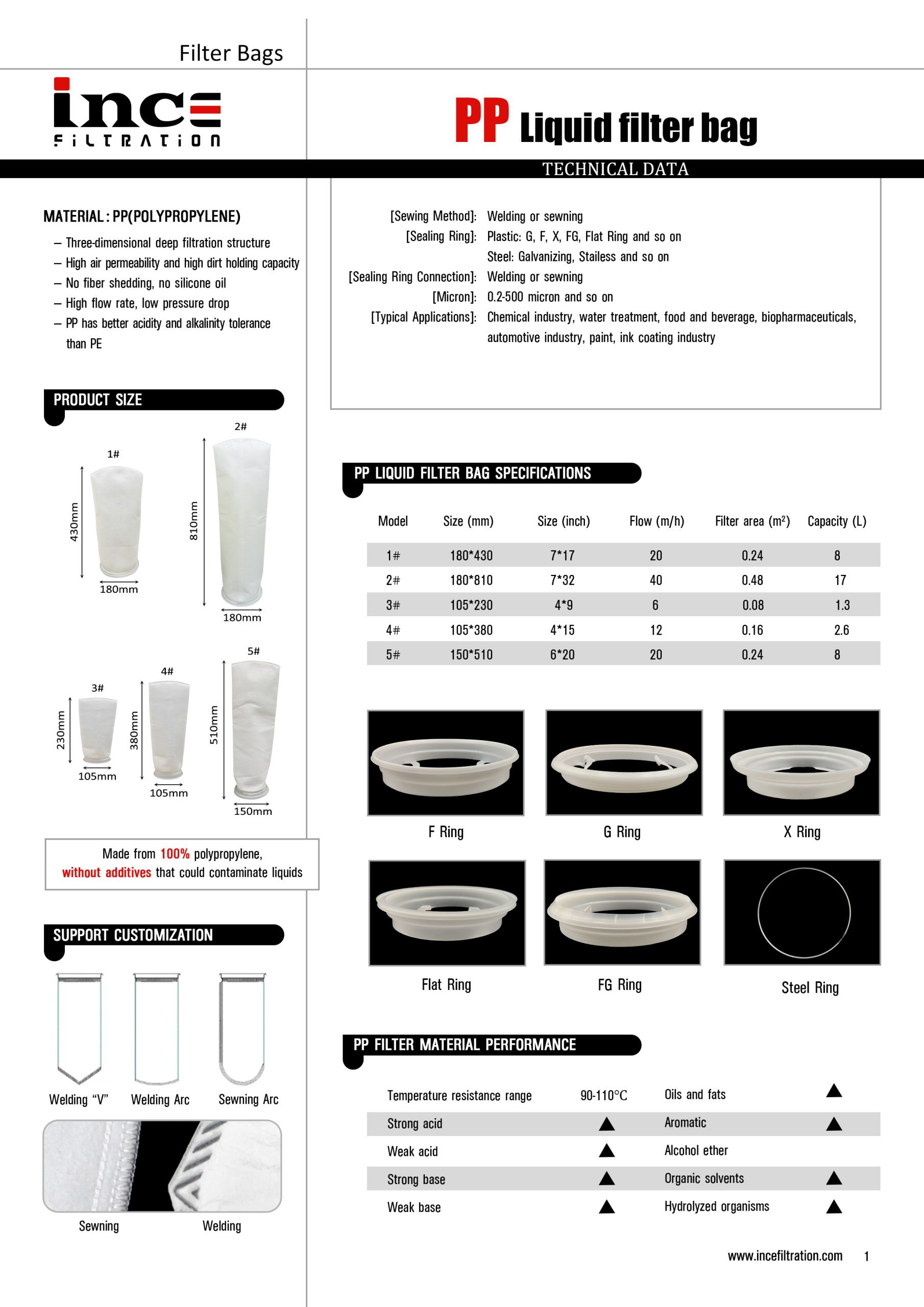

The structure of a PP liquid filter bag is designed to balance flow rate and particle retention. Needle-felt or mesh configurations allow liquid to pass efficiently while capturing suspended solids throughout the bag depth. This design helps distribute contaminant loading evenly, reducing the likelihood of sudden clogging and extending service life.

Compared with alternative materials, polypropylene maintains dimensional stability during continuous operation. This stability ensures proper sealing within the housing and minimizes the risk of bypass, a critical factor for bag filter for liquid filtration systems that operate under constant pressure.

Applications in Chemical and Water Treatment Systems

A PP liquid filter bag for chemical industry use is commonly installed to remove solid impurities from process liquids, intermediates, or final products. In these environments, consistent filtration protects downstream equipment such as pumps, heat exchangers, and membranes while helping maintain process quality. Polypropylene’s resistance to chemical attack makes it suitable for a wide range of formulations and operating conditions.

In water treatment, a PP liquid filter bag for water treatment serves as an effective pre-filtration or polishing stage. It removes sediment, rust, and particulate matter before water enters more sensitive treatment steps. This approach helps stabilize system performance and reduces the maintenance burden on downstream filtration components.

Across both sectors, liquid filtration bags made from polypropylene offer flexibility in micron ratings and bag sizes, allowing systems to be tailored to specific flow rates and contamination levels without redesigning housings.

Operational Value and Replacement Efficiency

Operational efficiency is closely tied to maintenance planning. A well-specified PP liquid filter bag replacement schedule helps prevent unexpected pressure increases and unplanned shutdowns. Because polypropylene filter bags provide predictable dirt-holding capacity, operators can establish consistent replacement intervals based on operating data rather than reactive maintenance.

Ease of installation and removal further enhances operational value. Standardized bag designs allow quick change-outs, reducing downtime and labor requirements. For facilities managing multiple filtration points, this simplicity translates into measurable cost and time savings.

From a supply perspective, working with a reliable PP liquid filter bag supplier ensures dimensional consistency and material quality across replacement cycles. Consistency in manufacturing reduces performance variation and supports stable filtration results over time.

Manufacturing Quality and Supplier Considerations

Selecting a capable PP Liquid Filter Bag Manufacturer is an important part of filtration system reliability. Manufacturing controls such as material traceability, controlled sewing or welding processes, and dimensional inspection contribute to uniform performance across production batches.

Industrial users often prioritize suppliers that can provide a range of bag sizes, micron ratings, and construction options to match different systems. This flexibility allows procurement teams to standardize on a trusted product line while adapting to varied applications within the same facility.

By combining material reliability, structural efficiency, and consistent manufacturing quality, polypropylene-based liquid filter bag solutions support dependable filtration in both chemical processing and water treatment. When properly selected and maintained, a PP Liquid Filter Bag becomes a stable, long-term component within industrial liquid filtration systems.