Pleated Filter Cartridges for Material and Structural Performance in Industrial Filtration

In many filtration systems, material selection and internal structure directly influence service life, filtration stability, and system compatibility. As operating conditions in water treatment and industrial processes become more demanding, users increasingly require filter cartridges that offer predictable performance, mechanical strength, and chemical resistance. Pleated Filter Cartridges are widely used to meet these requirements, particularly where consistent filtration and controlled pressure drop are essential.

Product Design Based on Material and Structural Engineering

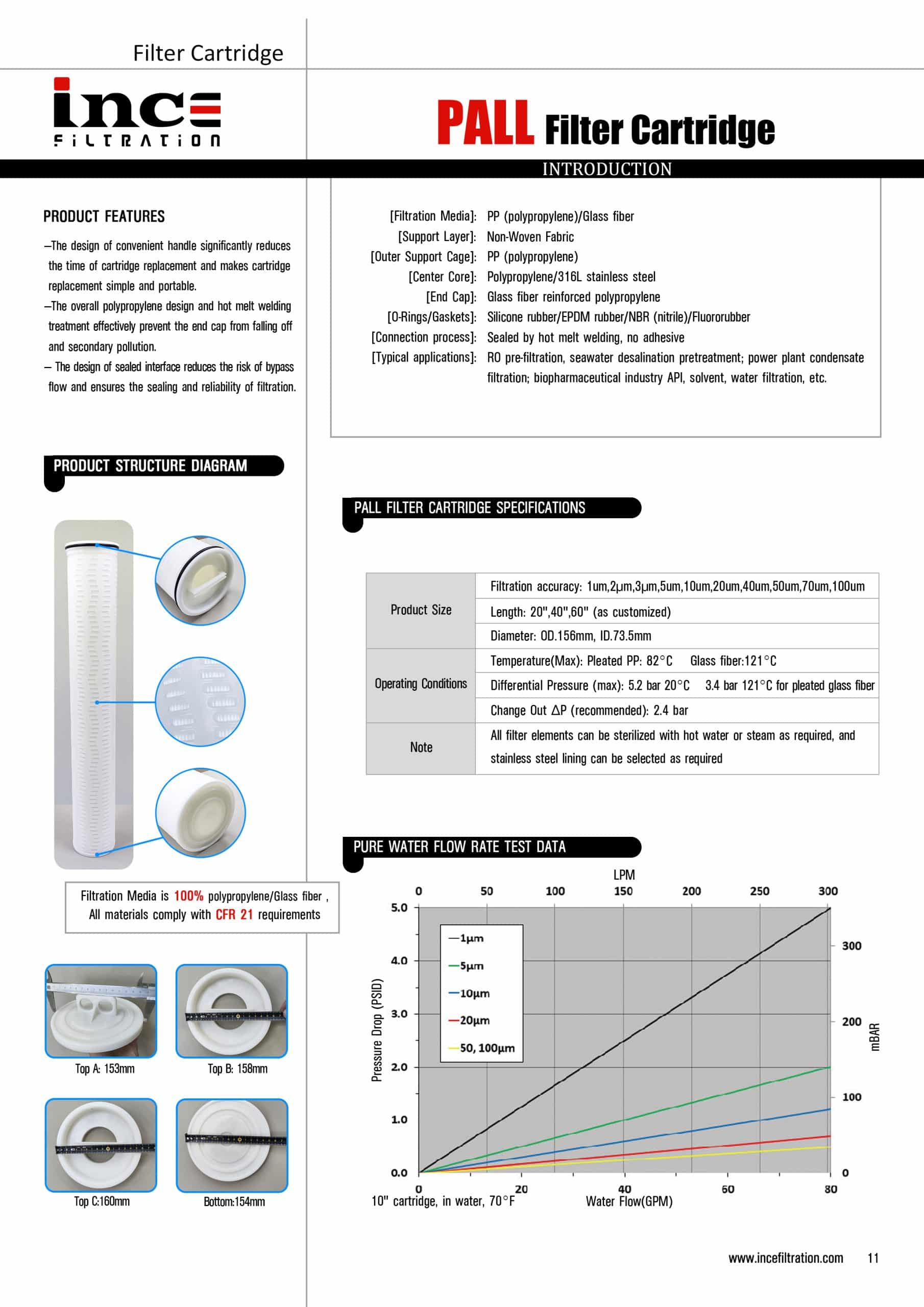

Pleated Filter Cartridges are constructed around pleated media that significantly increase effective filtration area while maintaining compact dimensions. This structural approach allows higher flow capacity and longer operating cycles compared with traditional depth filters, making them suitable for continuous-duty systems. In Industrial Pleated Filter Cartridges, the pleated configuration also supports uniform contaminant loading, reducing the risk of premature blockage.

Material selection plays a central role in performance. A polypropylene pleated filter cartridge is commonly chosen for applications requiring broad chemical compatibility and resistance to moisture, while a glass fiber pleated filter cartridge is preferred where higher temperature tolerance or finer particle retention is needed. These material options allow engineers to match cartridge construction with specific process conditions in industrial and water treatment systems.

Core Structure and Mechanical Stability

The internal support structure of Pleated Filter Cartridges is designed to maintain media integrity under varying flow rates and differential pressures. Options such as a pleated filter cartridge PP core provide lightweight structural support for general filtration applications, while a pleated filter cartridge with stainless steel core is used in systems exposed to higher mechanical stress or elevated temperatures.

This structural reinforcement ensures that pleats remain evenly spaced during operation, preventing media deformation and bypass. As a result, Industrial Pleated Filter Cartridges maintain stable filtration efficiency throughout their service life, supporting consistent process performance and reduced maintenance intervention.

Bonding Technology and Media Integrity

The method used to bond filtration media directly affects product reliability. A hot melt welded pleated filter cartridge offers strong, uniform bonding between components without introducing solvents or bonding agents that could contaminate the process fluid. This construction approach improves cartridge durability and ensures consistent performance under fluctuating operating conditions.

An adhesive free pleated filter cartridge is particularly valued in sensitive applications such as water treatment and chemical processing, where material purity and compatibility are critical. By eliminating adhesives, the risk of chemical interaction or material degradation is reduced, supporting long-term operational stability and regulatory compliance.

Application Alignment in Water Treatment and Industry

A Pleated Filter Cartridge for Water Treatment must balance filtration precision with mechanical reliability. The combination of pleated media, appropriate core material, and controlled bonding processes allows these cartridges to perform effectively in pre-filtration, process water polishing, and system protection roles.

Beyond water treatment, Pleated Filter Cartridges are widely integrated into industrial systems where predictable filtration behavior is required. By selecting appropriate materials and structures, users can adapt a single cartridge design across multiple applications while maintaining consistent performance standards.

Manufacturing Consistency and Selection Considerations

Working with an experienced Pleated Filter Cartridge Manufacturer is essential for ensuring dimensional accuracy, material consistency, and reliable performance across production batches. Manufacturing controls around media pleating, core alignment, and welding processes directly influence cartridge lifespan and filtration accuracy.

For engineers and procurement teams evaluating filtration solutions, understanding the relationship between material choice, internal structure, and bonding technology is critical. Well-designed Pleated Filter Cartridges provide a balanced solution for industrial filtration systems seeking long-term reliability, operational stability, and predictable maintenance cycles.