Pleated Filter Cartridges Designed for Stable Flow and Long-Term Filtration Performance

In many industrial filtration systems, consistent fluid quality is directly linked to production efficiency, equipment protection, and overall process reliability. As operating conditions become more demanding, filtration components are expected to deliver higher throughput while maintaining stable retention performance over extended service cycles. These expectations have led many operators to reassess traditional filtration formats and adopt solutions that provide both performance stability and operational flexibility.

Pleated filter cartridges have become a preferred choice in applications where space efficiency, predictable filtration behavior, and extended service life are required. By combining a compact cartridge structure with a pleated filter design, these filter cartridges support reliable particulate removal while helping users manage pressure drop, maintenance intervals, and long-term operating costs.

Engineered Structure of Pleated Filter Cartridges

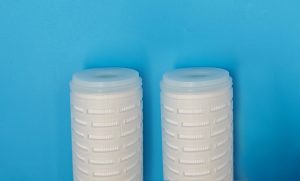

Pleated filter cartridges are designed around a folded filtration medium that significantly increases effective surface area within a standard cartridge format. This pleated filter structure allows more media to be housed in the same physical space compared with non-pleated alternatives, supporting higher flow rates without sacrificing filtration efficiency. As a result, pleated filter cartridges are well suited for systems where stable throughput is critical.

The cartridge configuration ensures uniform flow distribution across the entire pleated surface. Liquids or gases pass evenly through the pleated filter media, reducing localized loading and helping maintain consistent filtration performance throughout the service life of the cartridge. This balanced flow behavior is essential for protecting downstream equipment and ensuring predictable system operation.

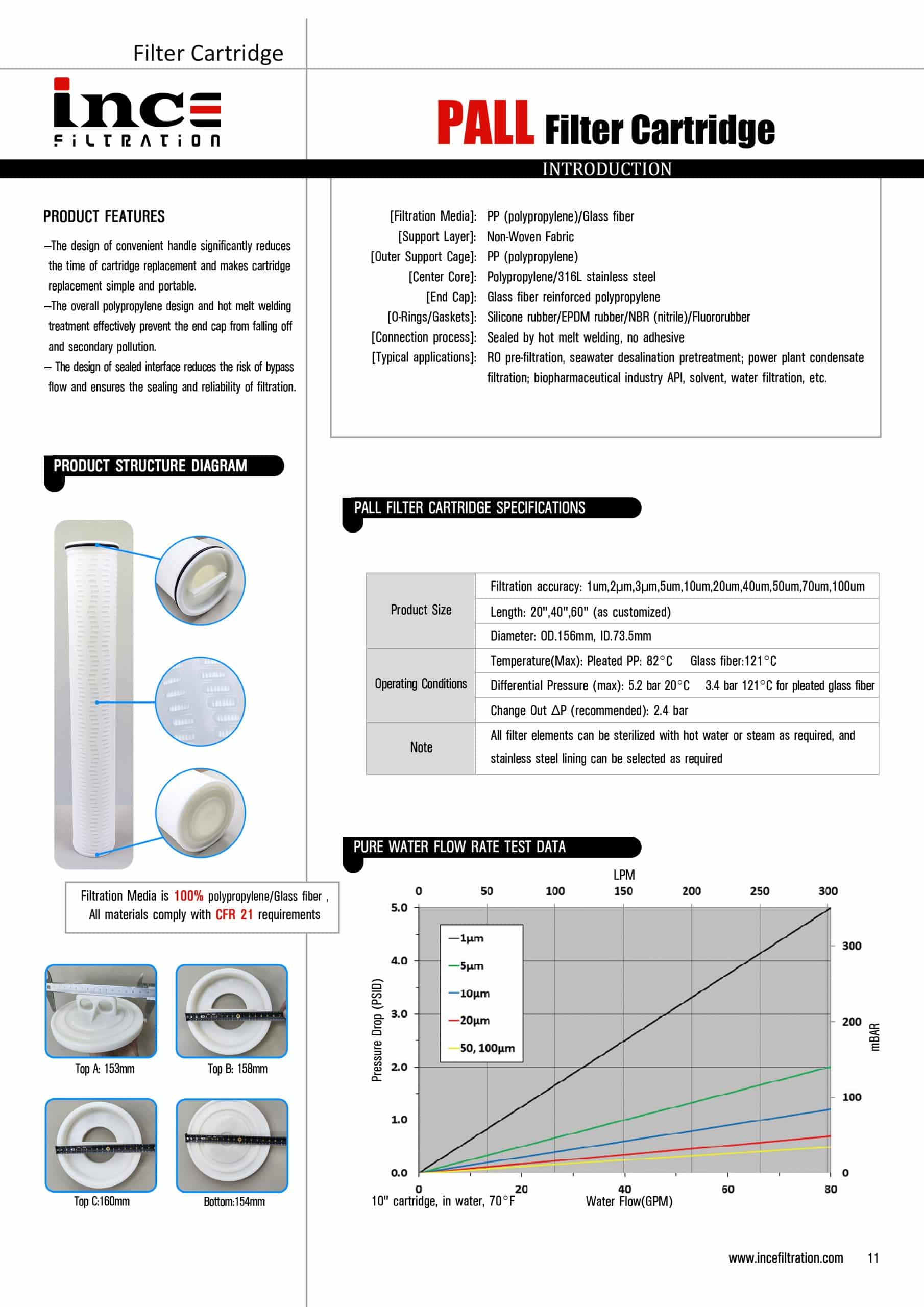

In addition to filtration efficiency, the structural integrity of pleated filter cartridges plays an important role in performance stability. Reinforced cores, end caps, and bonding methods help maintain the pleated shape under operating pressure, preventing collapse or deformation. This engineered structure allows filter cartridges to perform reliably in continuous or batch processes.

Filtration Performance and Operational Advantages

One of the primary advantages of pleated filter cartridges lies in their ability to deliver consistent filtration performance over extended operating periods. The increased surface area of the pleated filter reduces face velocity, which helps minimize pressure drop and slows the rate of contaminant loading. This characteristic supports stable system pressure and reduces the frequency of cartridge replacement.

Compared with conventional depth or surface filters, pleated filter cartridges offer more predictable retention behavior. The pleated filter media is manufactured with controlled pore structures, allowing users to select filter cartridges that align closely with required particle size ranges. This precision supports applications where filtration consistency directly affects product quality or process control.

Operational efficiency is further enhanced by the cartridge format itself. Filter cartridges can be easily installed and replaced within standard housings, reducing maintenance time and minimizing system downtime. For facilities managing multiple filtration points, the use of standardized pleated filter cartridges simplifies inventory management and maintenance planning.

Material Options and Application Compatibility

Pleated filter cartridges are available in a range of media and construction materials to support diverse industrial applications. Common pleated filter media include polypropylene, polyester, glass fiber, and blended synthetic materials, each offering specific performance characteristics related to chemical compatibility, temperature resistance, and filtration efficiency.

In water treatment and general industrial processes, polypropylene pleated filter cartridges are frequently selected due to their chemical resistance and broad compatibility with process fluids. Polyester-based pleated filter media provide enhanced mechanical strength and are often used in applications involving higher flow rates or abrasive particles. Glass fiber pleated filters are typically applied in processes requiring fine filtration and stable performance under controlled conditions.

The versatility of pleated filter cartridges allows them to be integrated into systems handling liquids, chemicals, and process fluids across multiple industries. Whether used in pre-filtration stages or as final polishing filters, these filter cartridges offer reliable performance without requiring complex system modifications.

System Efficiency and Long-Term Economic Value

From a system efficiency perspective, pleated filter cartridges contribute to improved overall filtration performance by maintaining stable pressure and flow characteristics. The pleated filter design distributes contaminants across a larger media area, reducing the risk of sudden blockage and allowing systems to operate smoothly over longer intervals.

This extended service life directly translates into economic benefits. Fewer cartridge change-outs reduce labor requirements and minimize production interruptions. Over time, the reduced frequency of maintenance and replacement helps lower total operating costs, especially in systems operating continuously or at high flow rates.

Pleated filter cartridges also support scalability in filtration system design. As process demands change, users can adjust filtration capacity by selecting different cartridge lengths, diameters, or micron ratings without redesigning the entire system. This flexibility provides long-term value for operations seeking adaptable and cost-efficient filtration solutions.

Quality Control and Manufacturing Consistency

The performance reliability of pleated filter cartridges depends heavily on manufacturing precision and quality control. Consistent pleat spacing, uniform media thickness, and secure bonding between components are essential to ensuring predictable filtration behavior. High manufacturing standards help ensure that each cartridge performs consistently across different production batches.

Dimensional accuracy is another critical factor for filter cartridges. Properly manufactured pleated filter cartridges fit securely within standard housings, preventing bypass and ensuring that all fluid passes through the intended filtration path. This secure fit supports stable filtration efficiency and protects downstream equipment.

Quality control processes typically include media inspection, flow testing, and structural integrity checks. These measures help verify that pleated filter cartridges meet defined performance specifications and provide users with confidence in long-term system reliability. Consistent manufacturing practices reduce variability and support dependable filtration outcomes in real-world applications.

For operations that require stable filtration performance, efficient system operation, and predictable maintenance planning, pleated filter cartridges offer a balanced and reliable solution. By combining a high-surface-area pleated filter design with a standardized cartridge format, these filter cartridges support consistent performance across a wide range of industrial filtration systems while delivering long-term operational value.