PARKER Filter Cartridge for Industrial Water Filtration

In industrial and process-driven environments, filtration components are expected to deliver stable performance under varying operating conditions while maintaining compatibility with complex systems. As requirements for water purity, process protection, and regulatory compliance continue to increase, filter cartridges must combine material reliability, structural integrity, and predictable filtration behavior. The PARKER Filter Cartridge is positioned to support these demands by providing a well-engineered solution for water filtration and critical industrial applications.

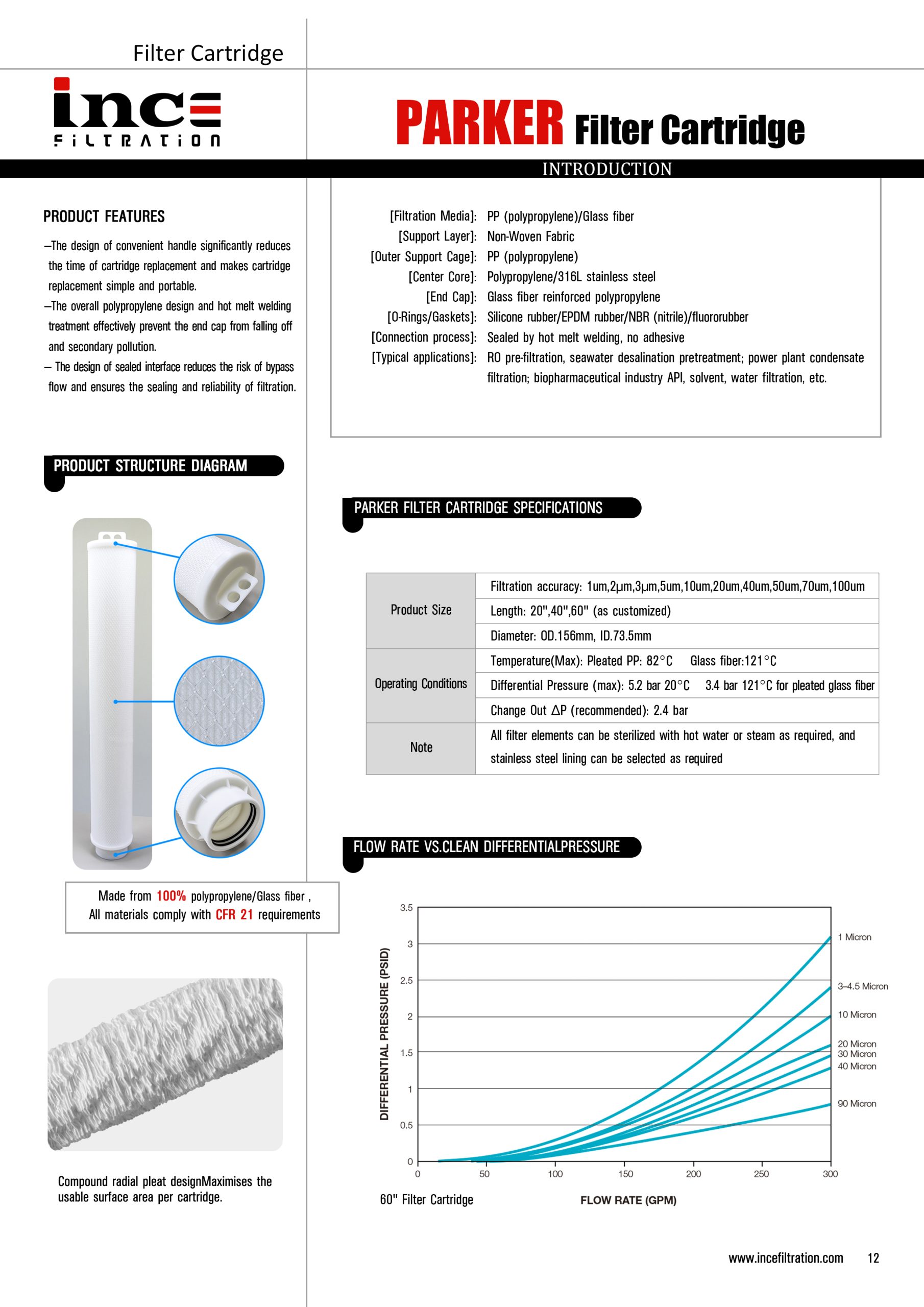

Product Structure and Design Concept

The PARKER Filter Cartridge is designed as a high-performance cartridge solution for liquid and water filtration systems. Its structure integrates multiple functional layers, each contributing to consistent filtration efficiency and mechanical stability. The filtration media is composed of polypropylene or glass fiber, selected to support controlled particle retention while maintaining stable flow characteristics across a wide range of operating conditions.

A support layer made of non-woven fabric reinforces the filtration media, helping distribute flow evenly and prevent localized stress during operation. This layered construction allows the filter cartridge to maintain its shape and performance even in continuous filtration processes. The outer support cage, manufactured from polypropylene, provides additional structural strength and protects the filtration media from deformation under pressure.

At the core of the cartridge, a center tube made from polypropylene or 316L stainless steel ensures mechanical stability and compatibility with demanding industrial environments. End caps reinforced with glass fiber polypropylene are securely bonded through a hot melt welding process, eliminating the need for adhesives. This connection method enhances structural integrity and reduces the risk of contamination, making the PARKER Filter Cartridge suitable for sensitive filtration applications.

Filtration Performance and Material Advantages

Consistent filtration performance is a key requirement for filter cartridges used in industrial water systems. The PARKER Filter Cartridge is engineered to deliver reliable particle removal while maintaining stable pressure behavior throughout its service life. The combination of polypropylene and glass fiber filtration media supports a wide range of micron ratings, enabling precise filtration control without sacrificing flow efficiency.

Material compatibility plays an essential role in long-term filtration stability. Polypropylene components provide excellent resistance to a broad range of chemicals, making these water filter cartridges suitable for both neutral and aggressive process fluids. For applications requiring enhanced mechanical strength or higher temperature tolerance, the option of a stainless steel center core adds durability and operational flexibility.

Sealing performance is further supported by the availability of multiple gasket and O-ring materials, including silicone rubber, EPDM rubber, nitrile rubber, and fluororubber. This flexibility allows the filter cartridges to be matched precisely to system requirements, reducing the risk of leakage and ensuring that all fluid passes through the intended filtration path. As a result, the PARKER Filter Cartridge maintains predictable filtration efficiency across diverse operating environments.

Application Scope in Industrial and Water Filtration Systems

The PARKER Filter Cartridge is widely used in applications where reliable pre-filtration and process protection are critical. In reverse osmosis pre-filtration systems, these water filter cartridges help remove suspended solids before fluids enter sensitive membranes. By reducing particulate load, the filter cartridges support stable membrane performance and extend overall system service life.

Seawater desalination pretreatment is another area where consistent filtration is essential. The robust construction and material compatibility of the PARKER Filter Cartridge make it suitable for handling challenging water conditions, including high salinity and variable particulate content. Stable filtration performance in these environments helps protect downstream equipment and maintain operational continuity.

In power generation facilities, filter cartridges are commonly used in condensate filtration systems to protect turbines and heat exchangers. The PARKER Filter Cartridge supports reliable contaminant removal in these applications, contributing to system efficiency and equipment longevity. Its consistent performance also makes it suitable for biopharmaceutical processes involving API production, solvent filtration, and high-purity water filtration, where process stability and material integrity are critical.

Operational Efficiency and Maintenance Value

From an operational perspective, the cartridge-based design of the PARKER Filter Cartridge supports efficient system maintenance and predictable service intervals. The standardized cartridge format allows for straightforward installation and replacement within compatible housings, reducing maintenance time and minimizing disruption to ongoing operations.

The hot melt welding connection process enhances reliability during long-term use. By eliminating adhesives, the filter cartridge reduces the risk of media separation or chemical interaction between bonding agents and process fluids. This design choice supports consistent performance across repeated filtration cycles and contributes to lower maintenance-related risks.

Extended service life is another important advantage of these filter cartridges. The layered filtration structure and stable materials allow contaminants to be distributed evenly throughout the media, delaying clogging and reducing replacement frequency. Over time, this operational efficiency translates into lower labor requirements, reduced downtime, and improved cost control for industrial filtration systems.

Manufacturing Consistency and Quality Assurance

The performance reliability of filter cartridges depends heavily on manufacturing precision and quality control. The PARKER Filter Cartridge is produced with strict control over material selection, layer alignment, and dimensional accuracy to ensure consistent performance across production batches. Uniform filtration media and controlled assembly processes help maintain predictable flow and retention characteristics.

Structural components such as the outer support cage, center core, and end caps are manufactured to maintain tight tolerances, ensuring proper fit within standard housings. Secure sealing with compatible O-rings and gaskets prevents bypass and supports stable filtration efficiency in water filter cartridges used across different systems.

Quality assurance processes focus on verifying structural integrity, material compatibility, and filtration performance under defined operating conditions. This attention to detail provides confidence to system designers and operators who rely on the PARKER Filter Cartridge for critical industrial and water filtration applications. By combining controlled manufacturing with robust design, these filter cartridges support long-term system reliability and consistent filtration outcomes.

For industrial operations that require dependable water filter cartridges capable of supporting demanding applications, the PARKER Filter Cartridge offers a balanced solution. Its engineered structure, material versatility, and application flexibility make it a practical choice for facilities seeking stable filtration performance and long-term operational value.