Optimize Your Process with Premium Liquid Filter Bags

Enhanced Liquid Filtration Bags for Industrial Excellence

When it comes to efficient liquid filtration bags, businesses across multiple industries depend on reliable performance, consistent quality, and cost-effective operation. Liquid filtration bags are engineered filter elements designed to trap solid particles, debris, and contaminants from fluid streams, ensuring downstream equipment protection and product quality improvement. These bags, often used in industrial bag housings where liquids pass through a permeable barrier, provide depth or surface filtration that accommodates a wide range of fluid viscosities and particulate loads. The versatility of liquid filtration bags makes them indispensable in water treatment, chemical processing, food and beverage production, pharmaceutical manufacturing, and petrochemical operations.

Industrial-grade liquid filter bags are constructed from advanced media such as felt, monofilament mesh, or multifilament weave, offering tailored filtration performance from coarse to fine micron ratings. Whether the application requires retaining large particles or achieving ultra-fine filtration for sensitive processes, these liquid filtration bags deliver high dirt-holding capacity with minimal pressure loss, optimizing operational efficiency and machine uptime. Customizable sizes and configurations of bag filters allow integration into existing systems with ease, minimizing retrofit costs and ensuring optimal compatibility.

Selecting the right liquid filtration bags can dramatically influence product quality and process reliability. Industry professionals seek bags that provide robust contaminant removal performance while also offering easy installation, rapid change-outs, and consistent service life—features that contribute directly to reduced maintenance demands and lower total cost of ownership.

Why Choosing the Right Liquid Filter Bag Matters

High-quality liquid filter bag manufacturers understand that the correct choice of filter media, micron rating, and structural design significantly impacts filtration results. For example, felt media offers exceptional depth filtration capable of capturing a wide range of particle sizes, whereas mesh media excels when surface filtration and reusability are priorities. Many leading manufacturers now offer extended life bags or multi-layer construction to improve efficiency and prolong service intervals.

The benefits of selecting scientifically designed liquid filter bags extend beyond particle capture alone. These bags play a crucial role in reducing equipment wear by preventing abrasive contaminants from circulating through pumps, valves, and sensitive downstream instruments. In food processing or pharmaceutical environments, using FDA-compliant filter bags ensures that product purity meets strict regulatory standards, protecting both consumer safety and brand integrity.

Furthermore, reliable liquid filter bag manufacturers offer technical guidance to help customers specify the ideal bag type for their unique application—balancing factors such as chemical resistance, operating temperature range, and flow rate requirements. This level of expert support ensures that every filter bag chosen enhances process performance and aligns accurately with the operational objectives of the facility.

Tailoring Bag Filter for Liquid Filtration to Your Needs

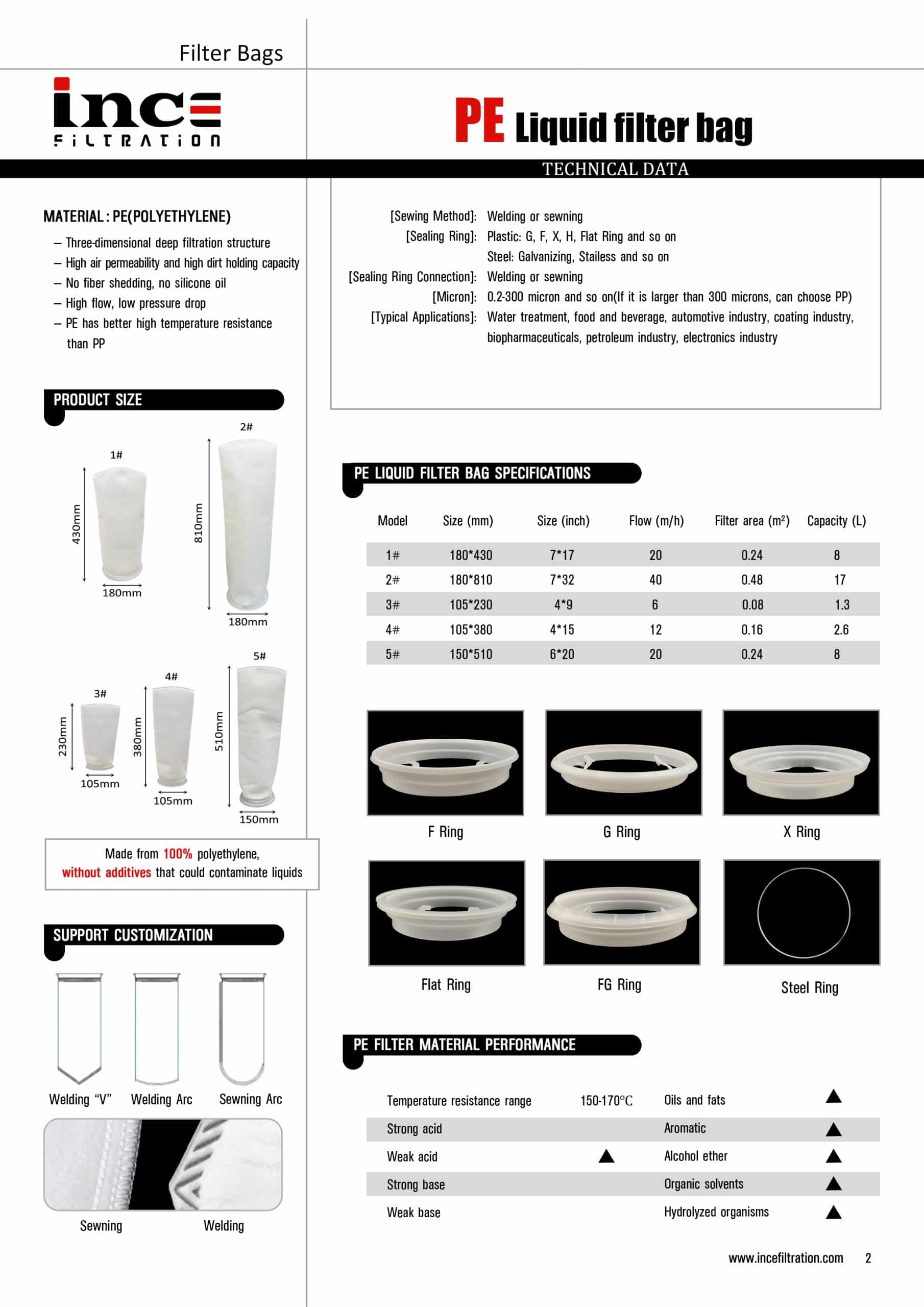

A well-engineered bag filter for liquid filtration is more than just a passive element; it is a precision-designed component that directly influences throughput, reliability, and purity levels. Bag filters can be configured with various seal ring types—such as steel, plastic, or snap-band collars—to ensure a tight fit in the housing, preventing bypass and ensuring that all fluid passes through the filter media. With micron ratings spanning from ultra-fine to coarse, operators can fine-tune their filtration systems for optimal performance in demanding applications.

Each bag filter for liquid filtration offers distinct advantages based on its construction. Welded seams can provide leak-proof integrity in high-pressure environments, while sewn seams offer cost-effective durability. Different bottom configurations and sizes—standard or custom—ensure that liquid filter bags fit a wide range of housings and flow conditions, catering to both new installations and retrofit projects alike.

The ability to customize liquid filtration solutions enhances the value delivered to operations across varied industrial sectors. Whether the priority is maximizing throughput, achieving precise final filtration, or extending bag life in abrasive environments, the wide spectrum of available bag filter options enables businesses to optimize performance while reducing downtime and operational expenses.

Industry Applications That Benefit from Liquid Filter Bags

Liquid filtration bags are integral to industries where fluid quality directly impacts product integrity and process efficiency. In water treatment facilities, they serve as primary filters to remove suspended solids before entering downstream purification stages. In chemical manufacturing, properly selected bags protect sensitive equipment from corrosive or particulate-laden fluids. In food and beverage operations, using FDA-approved bags ensures that consumable products maintain the highest safety and taste standards.

Pharmaceutical production lines often rely on bag filtration systems to remove contaminants from process liquids, ensuring that active ingredients and solvents meet stringent purity benchmarks. Similarly, in petrochemical and oil processing facilities, liquid filtration bags protect pumps and other costly equipment, reducing the risk of unscheduled downtime and costly repairs.

Across these diverse application areas, bag filters designed specifically for liquid filtration demonstrate their capability to balance performance with durability. Liquid filter bags that deliver consistent results can enhance plant reliability, reduce maintenance cycles, and help organizations meet regulatory compliance with confidence.