Large Stainless Steel Liquid Bag Filter Housing for High-Capacity Filtration

In industrial liquid processing, filtration capacity often determines system efficiency and operational stability. As production volumes increase and flow rates rise, standard-sized housings may no longer meet process demands. A Large Stainless Steel Liquid Bag Filter Housing is designed to support high-capacity filtration by accommodating larger filter bags and higher flow rates while maintaining reliable structural strength and sealing performance.

Product Overview and Core Design Concept

A Large Stainless Steel Liquid Bag Filter Housing is a heavy-duty filtration vessel engineered for applications requiring high throughput and continuous operation. The housing body is manufactured from stainless steel, providing mechanical strength, corrosion resistance, and durability under demanding industrial conditions.

Its enlarged internal volume allows the use of oversized filter bags or multiple standard bags, increasing dirt-holding capacity and extending service intervals. An internal support basket maintains the shape of the filter bag under high flow conditions, ensuring stable filtration performance throughout the operating cycle.

This core design enables the Large Stainless Steel Liquid Bag Filter Housing to function as a reliable filtration solution in systems where flow capacity and operational stability are critical.

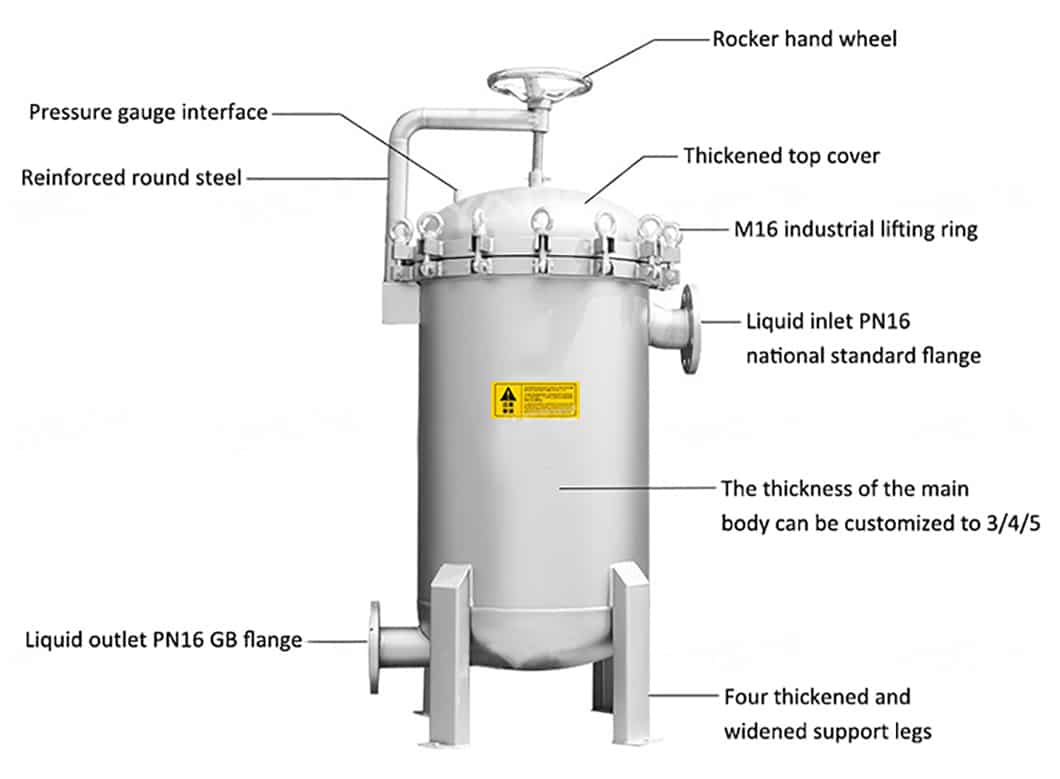

Structural Strength and Material Reliability

Material selection is central to the performance of a Large Stainless Steel Liquid Bag Filter Housing. Stainless steel construction offers excellent resistance to corrosion, pressure, and mechanical stress, which is essential for large-scale industrial filtration systems.

The robust housing design supports defined pressure ratings even at elevated flow rates. Welded seams and reinforced structures help maintain dimensional stability, reducing the risk of deformation or fatigue during long-term operation.

As a result, the Large Stainless Steel Liquid Bag Filter Housing provides dependable performance in applications where both size and strength are required to handle demanding process conditions.

Key Performance Advantages in High-Flow Filtration

One major advantage of a Large Stainless Steel Liquid Bag Filter Housing is its ability to handle significantly higher flow rates compared with standard housings. The increased filtration area reduces pressure drop, allowing fluids to pass through efficiently without compromising filtration effectiveness.

Another benefit lies in extended filter bag service life. Larger bags offer higher contaminant retention, which helps reduce replacement frequency and minimize process interruptions. This contributes to smoother operation and more predictable maintenance planning.

Compared with smaller housings, a Large Stainless Steel Liquid Bag Filter Housing supports higher productivity while maintaining consistent filtration performance.

Suitable Industrial Application Scenarios

A Large Stainless Steel Liquid Bag Filter Housing is widely used in industrial processes where large volumes of liquid must be filtered continuously. In water treatment and wastewater systems, it supports high-flow filtration of suspended solids and particulates.

In chemical and petrochemical processing, the housing is applied to filter process fluids, intermediates, or cooling water where throughput and material compatibility are critical. Stainless steel construction ensures reliable operation under chemically challenging conditions.

The housing is also suitable for food, beverage, and general manufacturing support processes, where stable filtration and efficient handling of large liquid volumes are required.

Operational Efficiency and Maintenance Considerations

Operational efficiency is a key advantage of a Large Stainless Steel Liquid Bag Filter Housing. The larger housing volume reduces the frequency of filter bag changes, helping minimize downtime in continuous processes.

Access features such as top-opening covers or quick-release clamps allow operators to replace filter bags safely and efficiently. The internal basket design ensures easy removal and installation of large filter bags without damage.

These maintenance-friendly features help the Large Stainless Steel Liquid Bag Filter Housing support consistent system uptime and streamlined operational workflows.

Long-Term Economic Value

From a cost perspective, a Large Stainless Steel Liquid Bag Filter Housing delivers strong long-term value. Although the initial investment may be higher than smaller housings, the reduction in maintenance frequency and increased filtration capacity contribute to lower operating costs over time.

Extended service intervals, reduced labor requirements, and improved system efficiency help offset upfront costs. Stainless steel durability further reduces the need for premature replacement, supporting long-term asset utilization.

For high-capacity filtration systems, this housing design offers a balanced approach to performance and cost control.

Manufacturing Quality and Configuration Flexibility

High-quality Large Stainless Steel Liquid Bag Filter Housing units are produced under controlled manufacturing processes to ensure structural integrity, accurate dimensions, and reliable sealing surfaces. These factors directly influence pressure resistance and filtration stability.

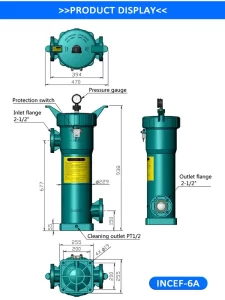

Multiple configurations are available, including different inlet and outlet sizes, housing diameters, and bag formats to match specific flow requirements. Surface finishes and connection standards can also be adapted to suit various industrial systems.

This flexibility allows the Large Stainless Steel Liquid Bag Filter Housing to be integrated seamlessly into diverse high-flow filtration applications.

Closing Perspective

For industrial operations requiring reliable filtration of large liquid volumes, the Large Stainless Steel Liquid Bag Filter Housing provides a practical and robust solution. Its combination of high-capacity design, stainless steel durability, and maintenance-friendly structure supports stable performance in demanding environments.

By addressing both throughput requirements and long-term operational efficiency, this housing configuration helps industrial filtration systems maintain consistent and dependable operation over extended service periods.