Industrial PP Liquid Filter Bags with Precise Micron Ratings

A PP Liquid Filter Bag is widely used in industrial liquid filtration systems where accurate particle retention and stable flow performance are essential. In processes that require defined micron control, polypropylene-based filter bags provide a reliable balance between filtration efficiency, chemical compatibility, and operational consistency.

As filtration requirements become more refined, engineers increasingly focus on micron-rated solutions that can be integrated into existing housings without compromising system stability. A Polypropylene Liquid Filter Bag designed with controlled construction and repeatable quality helps ensure that each filtration stage performs as intended over its service life.

Micron Rating Accuracy and Filtration Control

Precise micron ratings are critical when filtration performance directly impacts downstream processes. A 1 micron PP liquid filter bag or 1 micron water filter bag is typically used for fine particulate removal, protecting sensitive equipment or improving final liquid clarity. At this level, consistency in fiber structure and bag construction determines whether filtration results remain predictable.

For general industrial pre-filtration, a 5 micron PP liquid filter bag or 5 micron water filter bag offers an effective balance between flow rate and particle retention. These ratings are commonly applied where suspended solids must be reduced without excessive pressure loss, making them suitable for continuous operation systems.

Coarser filtration requirements are addressed with options such as the 10 micron PP liquid filter bag, 25 micron PP liquid filter bag, 50 micron PP liquid filter bag, and 100 micron PP liquid filter bag. These micron ranges are often used as pre-filters or bulk solids removal stages, helping extend the life of downstream filters while maintaining stable operating conditions.

Construction Methods and Structural Consistency

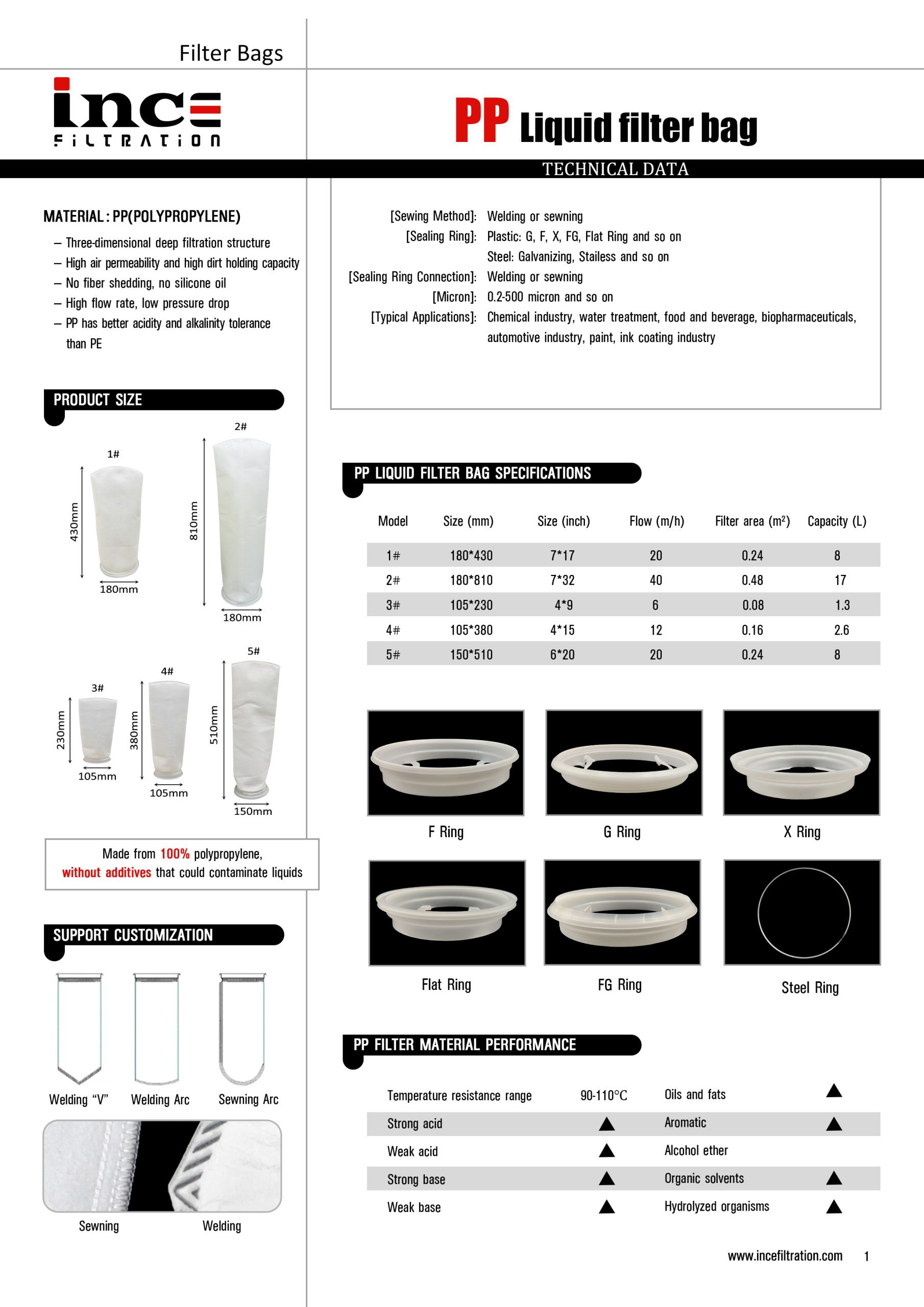

The construction method of a PP Liquid Filter Bag directly affects its strength and filtration reliability. A welded PP liquid filter bag is manufactured using thermal bonding, creating uniform seams without needle holes. This construction reduces the risk of bypass and is often selected for applications requiring higher cleanliness standards or consistent pressure behavior.

In contrast, a sewn PP liquid filter bag is produced using industrial stitching methods. While this construction is widely used and cost-effective, it relies on controlled sewing quality to ensure seam integrity. Sewn bags are commonly applied in general industrial filtration where operating pressures and cleanliness requirements are moderate.

Both construction types are available across multiple micron ratings, allowing users to select the appropriate balance between performance requirements and operational preferences. For an Industrial PP Liquid Filter Bag, choosing the right construction method supports long-term durability and predictable filtration results.

Ring Options and Housing Compatibility

Proper sealing within the filter housing is essential to prevent bypass and maintain micron-rated performance. A PP liquid filter bag with plastic ring is commonly used in water treatment and chemical applications where corrosion resistance and lightweight handling are preferred. Plastic rings provide stable sealing while maintaining compatibility with standard bag filter housings.

For more demanding environments, a PP liquid filter bag with steel ring offers enhanced mechanical strength and dimensional stability. Steel rings are often specified in higher-pressure systems or where repeated installation and removal require added durability.

Matching ring type to housing design ensures that the Polypropylene Liquid Filter Bag seats correctly and maintains consistent filtration efficiency. This compatibility reduces installation variability and supports stable performance across replacement cycles.

Industrial Applications and Operational Value

An Industrial PP Liquid Filter Bag is used across a wide range of sectors, including chemical processing, water treatment, coatings, and general manufacturing. In these applications, precise micron ratings allow operators to tailor filtration stages to specific contamination profiles, improving overall process control.

Accurate micron selection also supports cost efficiency. By selecting the appropriate rating, facilities can avoid premature clogging or unnecessary over-filtration, both of which increase operating costs. Consistent micron performance simplifies maintenance planning and helps establish reliable replacement intervals.

From a procurement perspective, working with a qualified PP Liquid Filter Bag Manufacturer ensures that micron ratings, construction methods, and ring options remain consistent across production batches. This consistency reduces performance variation and supports long-term system reliability.

Manufacturing Quality and Selection Considerations

Choosing a reliable PP Liquid Filter Bag Manufacturer is an important step in achieving dependable filtration performance. Controlled material sourcing, standardized manufacturing processes, and dimensional inspection all contribute to consistent micron accuracy and bag integrity.

Manufacturers that offer a full range of micron ratings, construction styles, and ring configurations allow users to standardize filtration solutions across different systems. This flexibility supports efficient inventory management while maintaining application-specific performance requirements.

By combining precise micron ratings, appropriate construction methods, and compatible sealing options, a PP Liquid Filter Bag becomes a dependable component in industrial liquid filtration systems. Proper selection ensures stable filtration results, reduced maintenance effort, and predictable operational performance over time.