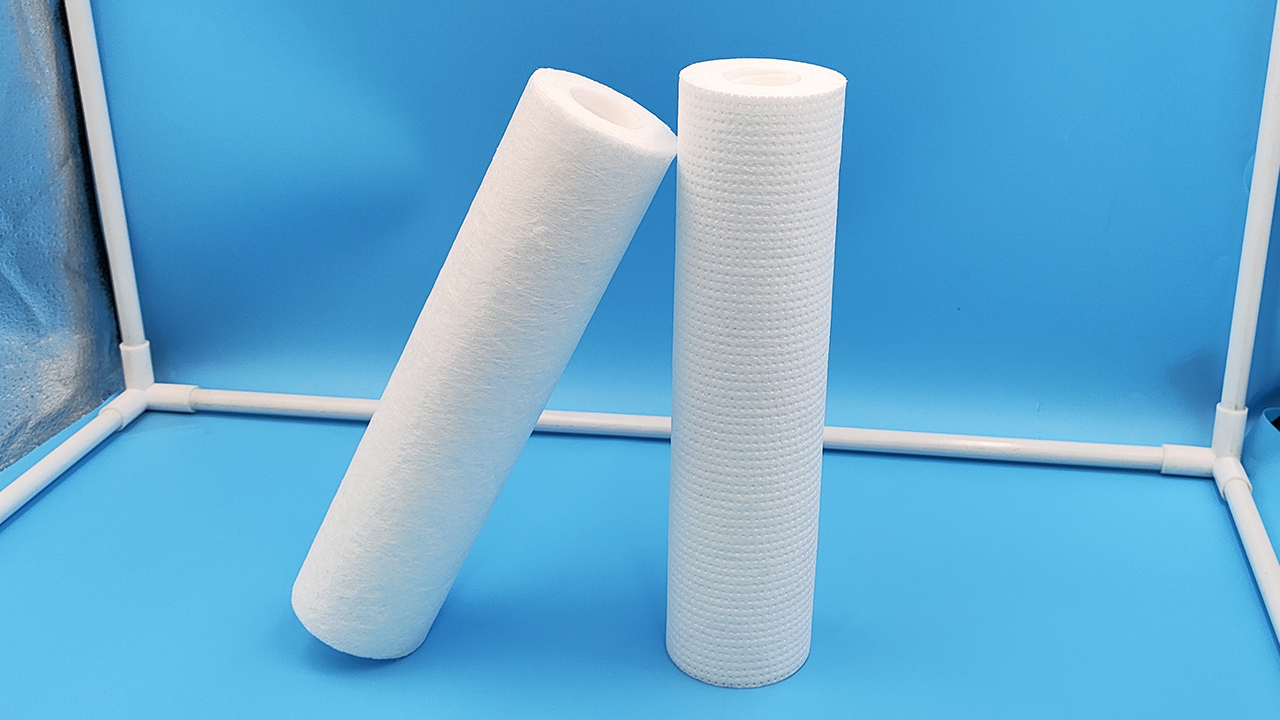

Industrial-Grade Melt Blown Polypropylene Filters for Consistent Particle Removal

# Industrial-Grade Melt Blown Polypropylene Filters for Consistent Particle Removal

Superior Filtration Technology

Melt blown polypropylene filters are engineered to provide exceptional filtration performance in various industrial applications. These filters utilize a unique manufacturing process that creates a dense, fine web of polypropylene fibers. This structure effectively captures particles and contaminants, ensuring that your operations maintain high standards of cleanliness and safety.

The advantages of using melt blown polypropylene filters extend beyond just particle removal. Their ability to filter fine particles makes them ideal for industries such as pharmaceuticals, food processing, and water treatment. By investing in these filters, you can enhance the reliability and efficiency of your filtration systems, ultimately leading to better product quality and reduced downtime.

Durable and Reliable Performance

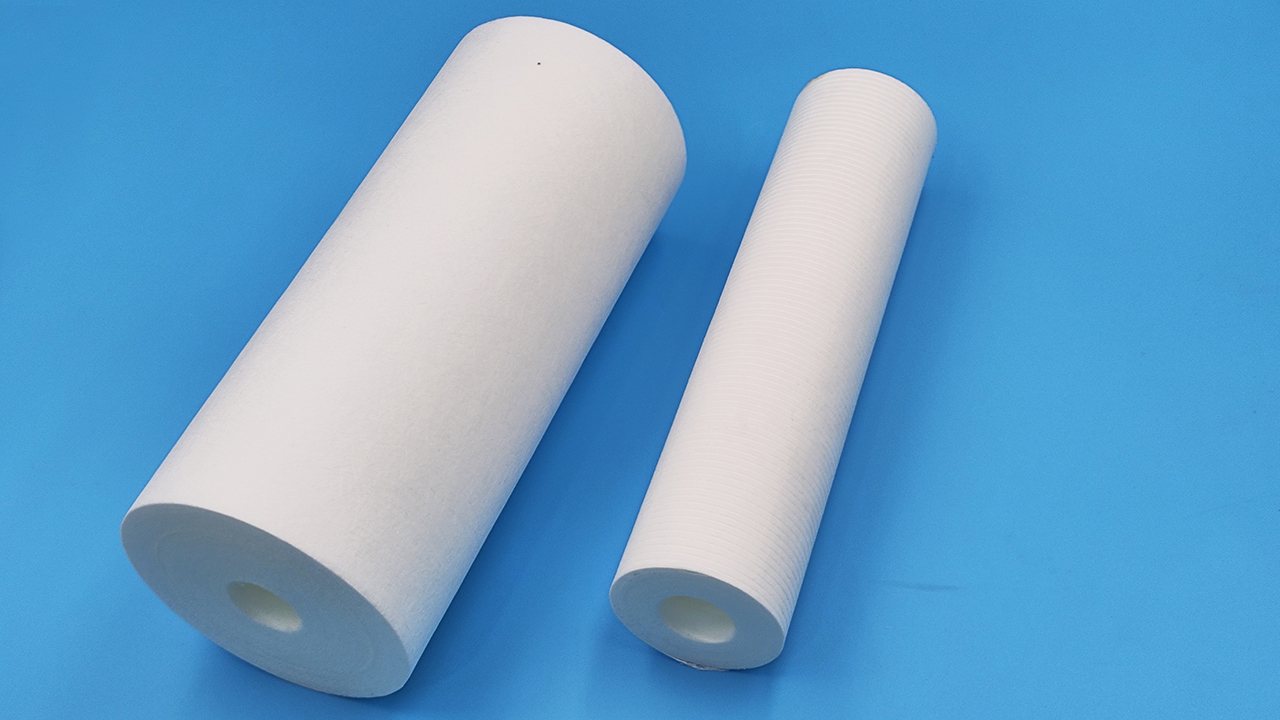

One of the key features of industrial-grade melt blown polypropylene filters is their durability. These filters are designed to withstand harsh conditions and operate effectively over extended periods. Their robust construction ensures that they can handle varying flow rates and temperatures without compromising performance.

In addition to their durability, melt blown polypropylene filters offer low pressure drop characteristics. This means that they can maintain consistent flow rates while efficiently removing contaminants. The result is a reliable filtration solution that minimizes energy costs and maximizes productivity in your operations.

Cost-Effective Solution

Investing in melt blown polypropylene filters is not only about performance; it’s also about cost-effectiveness. These filters typically have a longer lifespan compared to traditional filter media, which translates into lower replacement costs over time. Moreover, their high filtration efficiency reduces the need for frequent maintenance and system downtime.

By choosing industrial-grade melt blown polypropylene filters, you can achieve significant savings while ensuring optimal filtration. This combination of quality and economy makes them an ideal choice for businesses looking to enhance their operational efficiency without compromising on safety or compliance.

Versatile Applications

Melt blown polypropylene filters are incredibly versatile and can be utilized across various industries. Whether you are in the automotive, chemical, or healthcare sector, these filters can be tailored to meet your specific filtration needs. Their adaptability makes them suitable for pre-filtration, final filtration, and everything in between.

With the growing demand for clean and safe environments, the importance of effective filtration cannot be overstated. Industrial-grade melt blown polypropylene filters provide the reliability and performance necessary to meet industry standards and regulatory requirements, making them an essential component of any filtration system.

Easy Installation and Maintenance

Another advantage of melt blown polypropylene filters is their user-friendly design, which simplifies installation and maintenance. Most of these filters come in standard sizes, allowing for easy integration into existing filtration systems. Additionally, their lightweight construction makes handling and installation a hassle-free process.

Regular maintenance is critical for any filtration system’s longevity and efficiency. With melt blown polypropylene filters, cleaning and replacement procedures are straightforward. This ease of maintenance not only saves time but also ensures that your filtration system operates at peak performance with minimal interruptions.