Industrial Bag Filter Housing for Reliable Liquid Filtration

In many industrial liquid processes, stable filtration performance depends not only on the filter media but also on the integrity of the housing that supports it. As production environments become more demanding, issues such as leakage, pressure instability, corrosion, and difficult maintenance frequently arise when housings are not designed for industrial conditions. An Industrial Bag Filter Housing is specifically engineered to address these challenges by providing a secure, durable, and consistent platform for bag filtration systems. For operations that rely on continuous filtration, the housing plays a critical role in ensuring predictable system behavior and long-term reliability.

Product Overview and Core Concept

An Industrial Bag Filter Housing is a pressure-rated vessel designed to hold one or multiple filter bags and direct liquid flow through the filtration media in a controlled manner. Its primary function is to ensure that all process fluid passes through the filter bag without bypass, while maintaining mechanical strength under operating pressure. Compared with light-duty housings, an industrial design emphasizes structural rigidity, sealing consistency, and compatibility with demanding process conditions.

The internal structure of an Industrial Bag Filter Housing typically includes a support basket that maintains bag shape and prevents collapse under flow. The inlet and outlet configuration is engineered to promote even flow distribution, reducing localized loading and extending bag service life. These design elements make the housing suitable for continuous-duty systems in water treatment, chemical processing, and general industrial filtration.

Material selection is a fundamental aspect of the product concept. Stainless steel is commonly used for industrial applications due to its corrosion resistance, mechanical durability, and ease of cleaning. As a result, an Industrial Bag Filter Housing is often selected where long service life and stable operation are required across varying process conditions.

Structural Design for Industrial Reliability

The structural integrity of an Industrial Bag Filter Housing directly affects filtration performance and operational safety. Industrial housings are designed to withstand repeated pressure cycles, temperature fluctuations, and mechanical stress from frequent bag changes. Heavy-duty wall thickness, reinforced lids, and precision-machined sealing surfaces help maintain consistent gasket compression over time.

A key structural feature is the closure mechanism. Clamp-style, swing-bolt, or bolted cover designs are commonly used in Industrial Bag Filter Housing systems to ensure secure sealing while allowing practical access for maintenance. Proper closure design minimizes the risk of leakage and supports repeatable installation after each bag change, which is critical for maintaining filtration integrity.

Internal support baskets are another important component. In industrial systems, the basket must resist deformation caused by high flow rates or solids loading. A well-designed Industrial Bag Filter Housing ensures that the basket supports the filter bag evenly, reducing wear and preventing media damage during operation.

Key Performance Advantages

One of the main advantages of an Industrial Bag Filter Housing is its ability to maintain stable filtration performance over extended operating periods. By providing uniform flow distribution and reliable sealing, the housing helps the filter bag operate at its intended efficiency without premature clogging or bypass.

Pressure stability is another significant benefit. Industrial housings are engineered to handle higher differential pressures, which allows them to operate safely even as bags become loaded with contaminants. This performance characteristic supports predictable maintenance scheduling and reduces the likelihood of sudden system shutdowns.

Chemical compatibility further enhances performance value. An Industrial Bag Filter Housing made from appropriate materials can be used with a wide range of liquids, including water, oils, solvents, and process chemicals. This versatility allows a single housing design to be deployed across multiple applications within the same facility, simplifying system design and spare parts management.

Application Scenarios in Industrial Filtration

An Industrial Bag Filter Housing is widely used in water and wastewater treatment systems, where it serves as a pre-filtration or polishing stage. In these applications, the housing protects downstream equipment such as membranes, pumps, and heat exchangers by removing suspended solids and particulate contaminants.

In chemical processing environments, industrial housings support filtration of aggressive or variable fluids. Their corrosion-resistant construction and robust sealing performance make them suitable for batch and continuous processes alike. The ability of an Industrial Bag Filter Housing to accommodate different bag materials allows operators to adjust filtration performance without modifying the housing itself.

Manufacturing and general industrial processes also rely heavily on bag filter housings. Coolants, lubricants, and process water often require particulate control to maintain equipment performance. In these scenarios, the durability and serviceability of an Industrial Bag Filter Housing contribute directly to process stability and reduced maintenance effort.

Operational and Economic Value

From an operational standpoint, an Industrial Bag Filter Housing supports efficient maintenance practices. Quick-access lid designs and standardized bag sizes reduce the time required for bag changes, helping maintenance teams minimize downtime. Reliable sealing also reduces cleanup requirements and lowers the risk of process fluid loss during servicing.

Economically, the long service life of an industrial housing contributes to lower total cost of ownership. While the initial investment may be higher than non-industrial alternatives, the reduced frequency of replacement and lower maintenance-related disruptions often offset this cost over time. An Industrial Bag Filter Housing also helps extend the life of filter bags by ensuring proper support and flow conditions.

Standardization is another economic advantage. Using the same Industrial Bag Filter Housing design across multiple filtration points allows facilities to streamline inventory and simplify operator training. This consistency improves maintenance efficiency and reduces the likelihood of installation errors.

System Integration and Installation Considerations

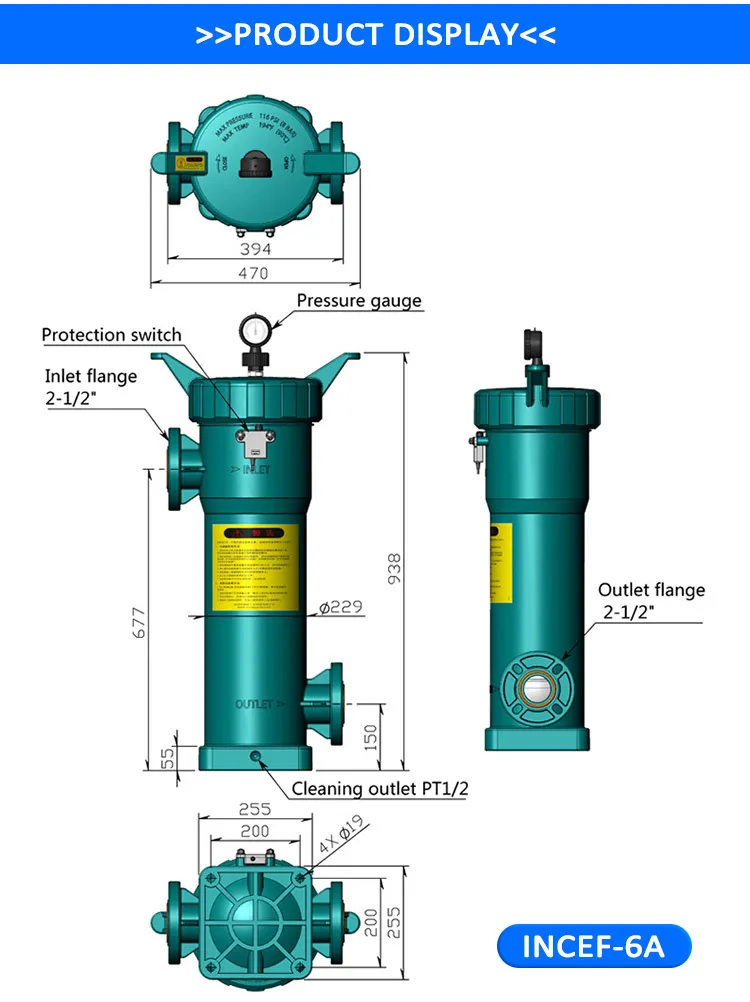

Successful implementation of an Industrial Bag Filter Housing depends on proper integration into the overall filtration system. Connection types, such as flanged or threaded ports, must be selected to match existing piping standards. Proper inlet and outlet orientation is essential to ensure smooth flow and adequate access for maintenance.

Space and accessibility are also important factors. Industrial housings are often installed in tight mechanical rooms or skid-mounted systems, making clearance for lid removal and bag replacement a critical design consideration. A well-chosen Industrial Bag Filter Housing balances compact footprint with sufficient service space.

Instrumentation support further enhances system integration. Pressure gauges or differential pressure indicators are commonly installed on industrial housings to provide real-time feedback on filter condition. This monitoring capability helps operators determine the optimal timing for bag changes and maintain stable process operation.

Manufacturing Quality and Consistency

The performance of an Industrial Bag Filter Housing is closely linked to manufacturing quality. Precision fabrication ensures dimensional accuracy, proper alignment of internal components, and consistent sealing surfaces. Welding quality, surface finish, and material traceability all influence the housing’s durability and reliability.

Quality control processes such as pressure testing and visual inspection help verify that each Industrial Bag Filter Housing meets design specifications before installation. Consistent manufacturing standards ensure that housings perform predictably across different installations, which is especially important for large-scale or multi-site operations.

Selecting a manufacturer with experience in industrial filtration equipment provides additional assurance. Established producers understand application requirements and can offer guidance on housing configuration, material selection, and accessory options to match specific operating conditions.

Long-Term Use and Selection Perspective

When viewed over the full lifecycle of a filtration system, an Industrial Bag Filter Housing represents a strategic component rather than a consumable item. Its design influences filtration efficiency, maintenance frequency, and system reliability for years of operation. Choosing a housing that matches process demands reduces operational risk and supports consistent performance.

For engineers and procurement teams, evaluating housing design, material quality, and serviceability is essential. An appropriately specified Industrial Bag Filter Housing provides a stable foundation for bag filtration, allowing process adjustments to be made through bag selection rather than equipment replacement.

By focusing on durability, compatibility, and ease of maintenance, industrial bag filter housings support dependable filtration across diverse industrial environments. Their role in protecting equipment, stabilizing processes, and controlling operating costs makes them a core element of effective industrial filtration systems.