Pall Filter Cartridges Designed for High Flow Filtration Efficiency and System Stability

In many large-scale industrial filtration systems, maintaining stable flow while achieving reliable contaminant removal is a constant operational challenge. As production volumes increase and system footprints become more compact, filtration components are required to handle higher throughput without compromising filtration performance or causing excessive pressure drop. These demands have driven the adoption of high-capacity filtration solutions specifically engineered for demanding flow conditions.

Pall filter cartridges are widely recognized in this context for their ability to support high flow operation while maintaining consistent filtration performance. Designed as advanced high flow filter cartridges, they address common pain points such as limited flow capacity, frequent cartridge replacement, and unstable differential pressure. By integrating robust cartridge construction with optimized filtration media, pall filter cartridges offer a practical solution for modern industrial filtration systems.

Engineered Structure for High Flow Filtration Systems

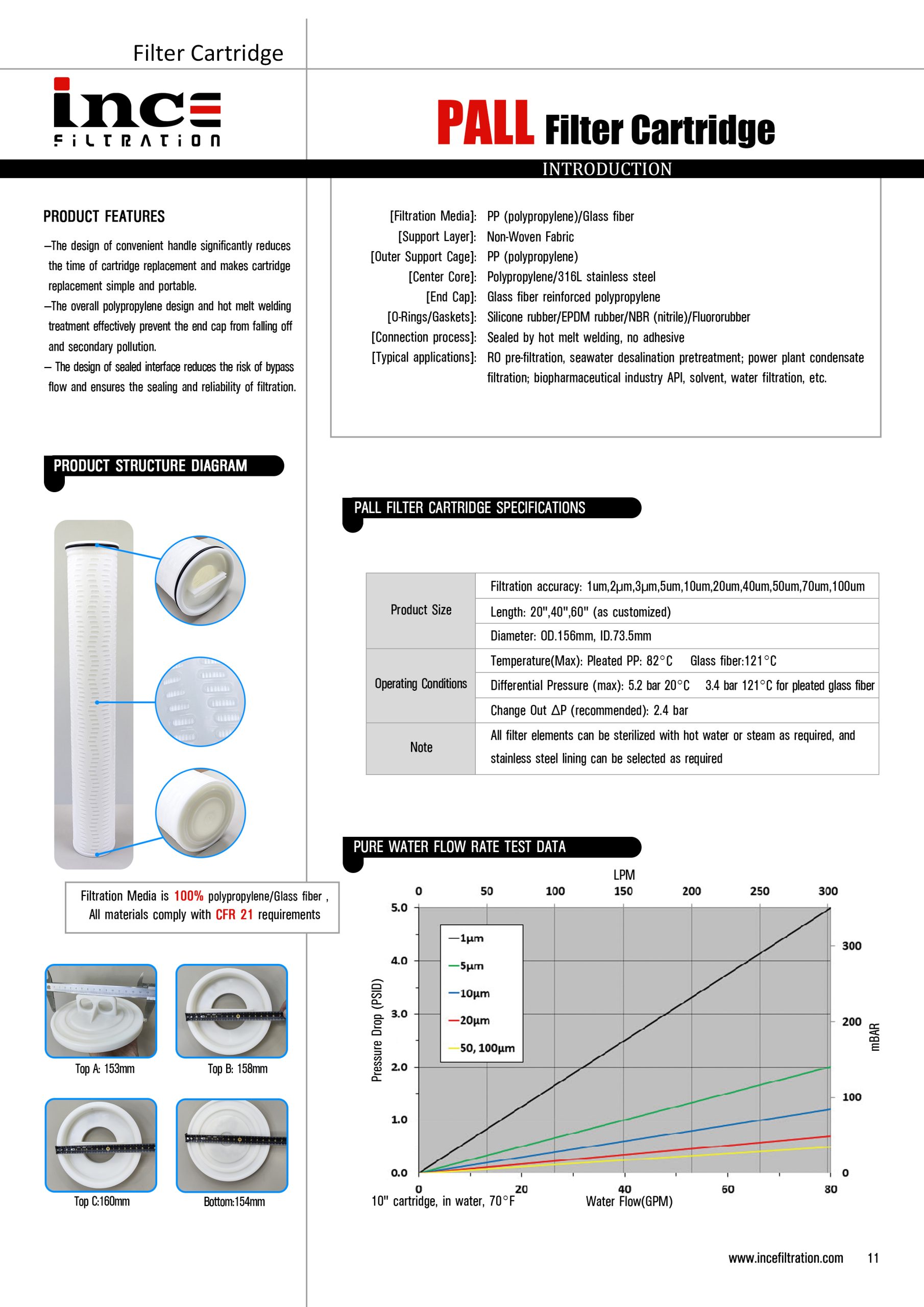

High flow filter cartridges are structurally different from conventional filter cartridges, as they are designed to process significantly higher volumes of fluid within a single element. Pall filter cartridges utilize a large-diameter cartridge format that allows fluids to flow from the inside out, reducing flow resistance and supporting stable system pressure even under high flow conditions.

The internal construction of these filter cartridges is engineered to ensure uniform flow distribution across the filtration media. This design minimizes localized loading and prevents premature blockage, which is a common issue in traditional cartridge configurations. As a result, high flow operation can be maintained without sacrificing filtration efficiency or system reliability.

Structural integrity is another key aspect of pall filter cartridges. Reinforced cores, secure end-cap designs, and controlled media bonding help maintain cartridge stability during continuous operation. This robust construction ensures that the filter cartridges retain their shape and performance characteristics even in systems operating at elevated flow rates and pressures.

Filtration Performance and High Flow Capability

One of the defining characteristics of high flow filter cartridges is their ability to deliver consistent filtration performance under demanding throughput requirements. Pall filter cartridges are designed to manage high flow rates while maintaining controlled particle retention, supporting both pre-filtration and final filtration stages in complex systems.

The high flow design reduces face velocity across the filtration media, which helps stabilize pressure drop and extend cartridge service life. By distributing contaminants evenly across a larger filtration area, these filter cartridges delay clogging and maintain predictable performance over time. This behavior is particularly valuable in systems where unplanned shutdowns can disrupt production schedules.

Compared with standard filter cartridges, high flow filter cartridges allow users to achieve the same or greater system capacity with fewer elements. This consolidation reduces housing size requirements and simplifies system layout, making pall filter cartridges an efficient choice for facilities seeking to optimize both performance and space utilization.

Application Suitability Across Industrial Sectors

Pall filter cartridges are commonly applied in industries where high flow filtration is essential to maintaining process continuity. In water treatment and desalination systems, high flow filter cartridges support large volumes of water while removing suspended solids that could affect downstream processes. Their stable performance helps ensure consistent water quality under variable operating conditions.

In power generation and energy-related applications, filter cartridges must handle continuous flow while protecting critical equipment. High flow pall filter cartridges are used to remove particulate contaminants from cooling water, process fluids, and other utility streams, supporting equipment reliability and reducing maintenance requirements.

Chemical processing and industrial manufacturing environments also benefit from the high flow capability of these filter cartridges. Pall filter cartridges offer material compatibility and structural stability that allow them to perform reliably in systems handling diverse process fluids. Their ability to operate efficiently at high flow rates makes them suitable for both centralized and distributed filtration systems.

Operational Efficiency and Economic Value

From an operational standpoint, high flow filter cartridges provide clear efficiency advantages. The reduced number of cartridges required for a given flow rate simplifies installation, inspection, and replacement procedures. Maintenance teams can manage filtration systems more effectively, reducing labor time and minimizing system downtime.

The extended service life of pall filter cartridges contributes to long-term economic value. By maintaining stable pressure drop and delaying clogging, these filter cartridges reduce the frequency of change-outs. This characteristic is particularly important in continuous operations where shutdowns carry significant cost implications.

High flow filtration also supports overall system efficiency by reducing energy consumption associated with pressure losses. When flow resistance is minimized, pumps and associated equipment can operate more efficiently. Over time, the combined benefits of reduced maintenance, lower energy demand, and extended cartridge life support a favorable total cost of ownership.

Manufacturing Consistency and Quality Assurance

Consistent performance in high flow filtration applications depends on precise manufacturing and quality control. Pall filter cartridges are produced under controlled processes that ensure uniform media structure, accurate dimensions, and reliable bonding between components. These factors are critical for maintaining predictable filtration behavior across multiple operating cycles.

Quality assurance practices focus on verifying flow characteristics, structural integrity, and filtration efficiency. Each batch of filter cartridges is designed to meet defined performance parameters, providing users with confidence in system reliability. This consistency is especially important in high flow systems where minor variations can have a significant impact on overall performance.

For operations seeking dependable high flow filtration solutions, manufacturing consistency plays a key role in long-term success. Pall filter cartridges combine engineered design with controlled production standards to deliver filter cartridges that support stable high flow operation and reliable filtration outcomes.

For industrial systems that require high throughput, predictable filtration performance, and efficient system design, pall filter cartridges provide a balanced and reliable solution. By integrating high flow capability with robust cartridge construction, these high flow filter cartridges support stable operation across a wide range of demanding industrial applications while delivering long-term operational value.