High-Efficiency PP Liquid Filter Bags for Paint and Ink Filtration

A PP Liquid Filter Bag is widely used in paint and ink filtration processes where pigment stability, viscosity control, and surface finish quality are critical. In these applications, filtration must efficiently remove gels, agglomerates, and process contaminants without affecting color consistency or flow properties. Industrial liquid filter bag polypropylene solutions provide a practical balance of filtration accuracy, chemical compatibility, and operational efficiency for modern coating and ink production lines.

Why Polypropylene Is Suitable for Paint and Ink Filtration

A Polypropylene Liquid Filter Bag offers excellent resistance to solvents, resins, and additives commonly found in paints and inks. This chemical stability allows the filter media to maintain structural integrity throughout the filtration cycle, even when exposed to aggressive formulations. An Industrial PP Liquid Filter Bag also features low extractables, helping prevent unwanted interactions with sensitive pigments or binders.

In high-throughput systems, polypropylene fibers support consistent depth filtration, capturing both coarse particles and fine contaminants. This makes a PP liquid filter bag for paint and ink filtration suitable for protecting downstream equipment such as pumps, filling systems, and spray nozzles.

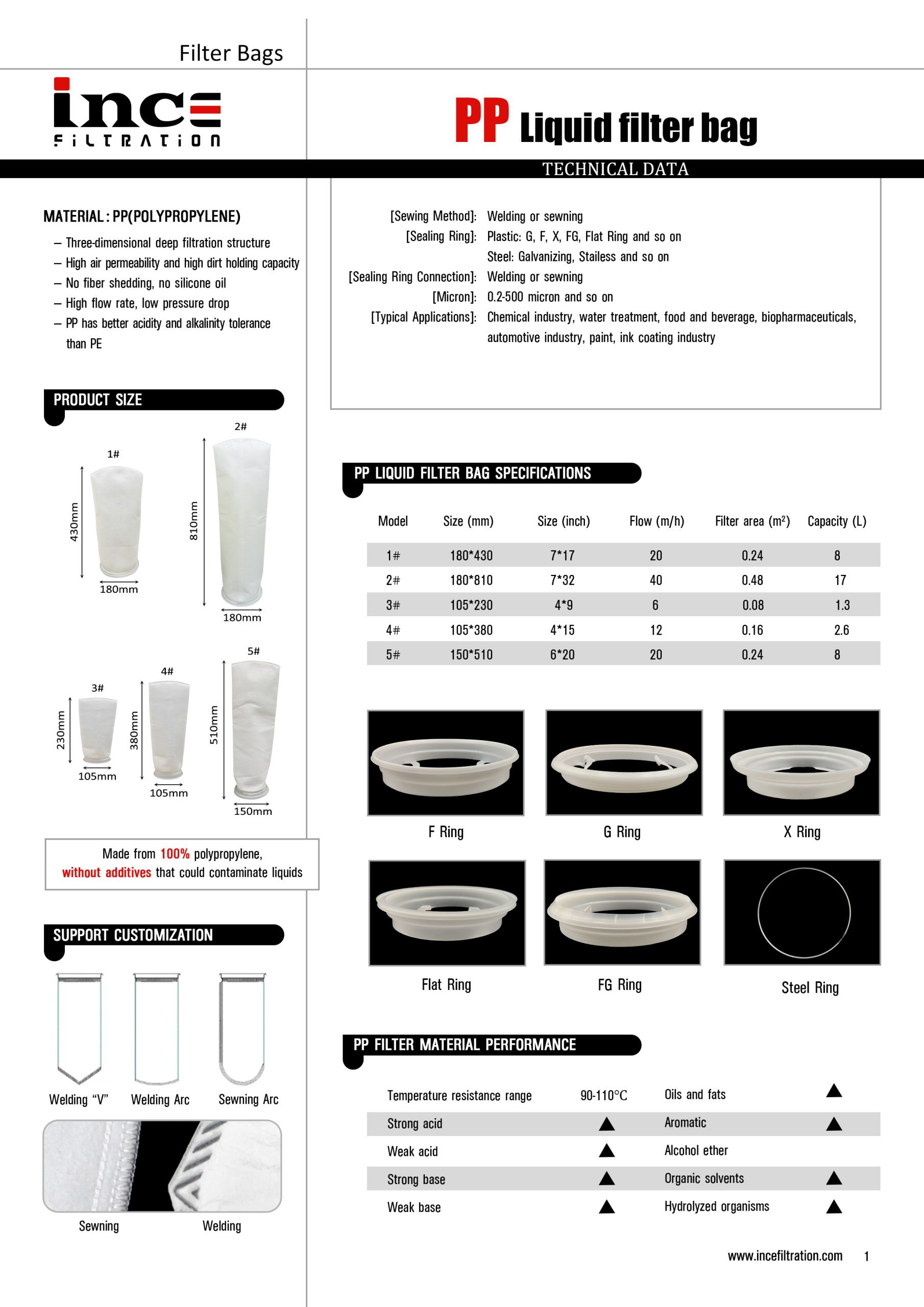

Welded vs. Sewn Construction Options

Construction method directly impacts filtration reliability. A welded PP liquid filter bag is produced through thermal bonding, creating smooth, sealed seams without needle holes. This design minimizes bypass and fiber shedding, which is particularly important in ink filtration where even small contaminants can affect print quality.

A sewn PP liquid filter bag is commonly used in less critical stages or where operating pressures are moderate. When manufactured under controlled conditions, sewn designs provide stable performance and flexibility across a wide range of bag sizes and micron ratings. Both welded and sewn options are available within industrial liquid filter bag polypropylene product lines to match different process requirements.

Ring Types and Housing Compatibility

Proper sealing between the bag and housing is essential to ensure all process liquid passes through the filter media. A PP liquid filter bag with plastic ring is frequently selected for paint and ink systems due to its corrosion resistance and ease of handling. Plastic rings are well suited for standard bag housings and routine maintenance operations.

For higher-pressure systems or frequent change-outs, a PP liquid filter bag with steel ring provides added mechanical strength and dimensional stability. Steel rings maintain a consistent seal under demanding conditions, helping prevent leakage and bypass in continuous production environments.

Performance in Paint and Ink Applications

A PP liquid filter bag for paint and ink filtration helps remove pigment clumps, dried particles, and manufacturing debris before filling or application. Depth filtration distributes contaminant loading throughout the bag, supporting longer service life and more stable pressure drop behavior.

An Industrial PP Liquid Filter Bag is often used at multiple stages of the process, from raw material filtration to final product polishing. Selecting the appropriate micron rating ensures effective contaminant removal while preserving desired rheological properties.

Supply Consistency and Replacement Strategy

Routine PP liquid filter bag replacement is essential for maintaining filtration efficiency and consistent product quality. Monitoring pressure differential and flow rate changes helps determine optimal replacement intervals and reduces the risk of unexpected downtime.

Partnering with a reliable PP liquid filter bag supplier ensures consistent dimensions, material quality, and construction standards across production batches. An experienced PP Liquid Filter Bag Manufacturer can support long-term supply stability, customization options, and technical guidance, enabling paint and ink producers to optimize filtration performance while maintaining operational continuity.