Choosing the Right PP Liquid Filter Bag for Your Process

A PP Liquid Filter Bag is a core component in many industrial liquid filtration systems, directly influencing filtration efficiency, system stability, and operating costs. Selecting the appropriate bag configuration requires more than matching size and micron rating; construction method, sealing design, and supplier consistency all affect long-term performance. For engineers and procurement teams, understanding these factors helps ensure that filtration solutions align with actual process conditions rather than theoretical specifications.

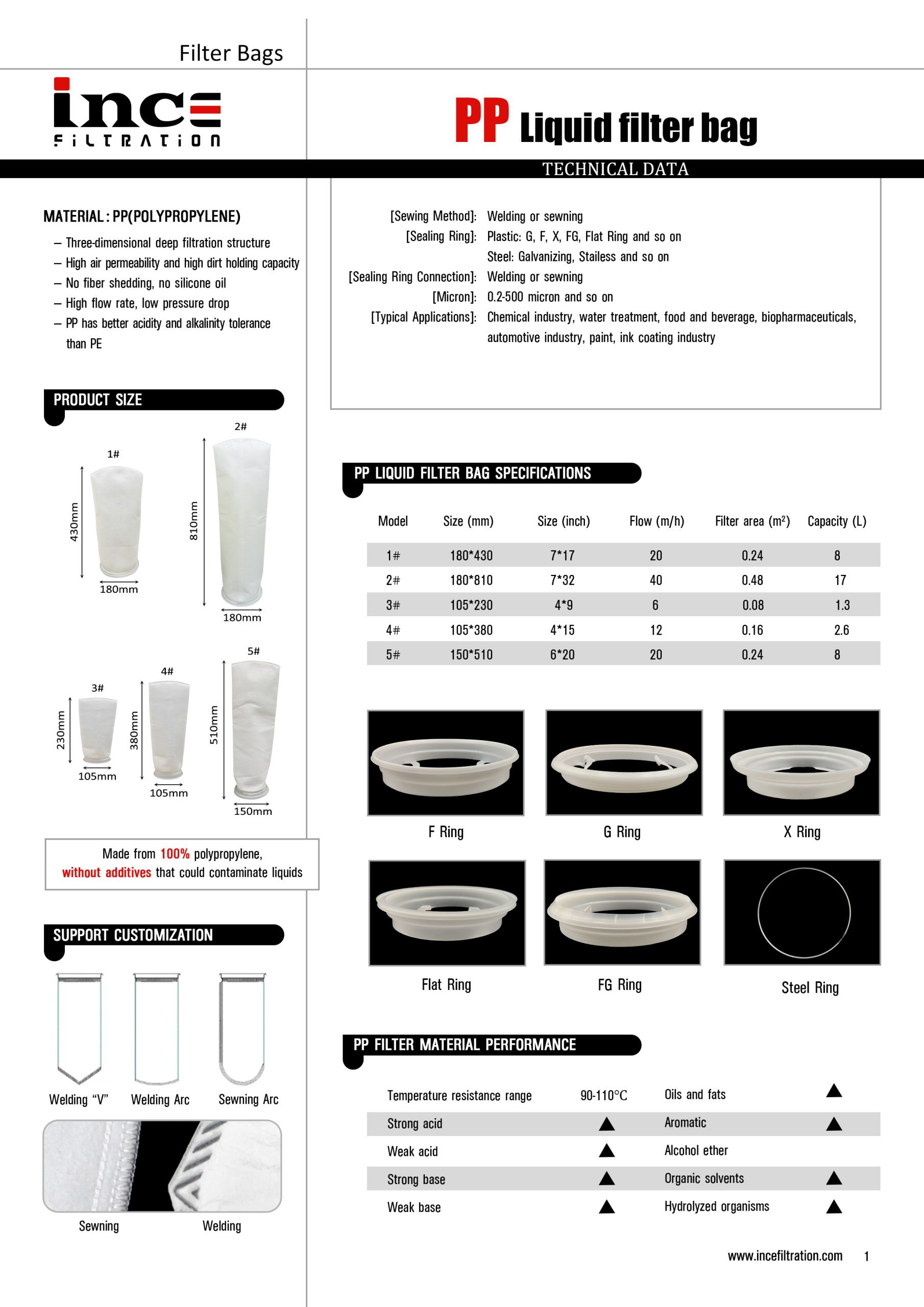

Material Fundamentals and Industrial Suitability

A Polypropylene Liquid Filter Bag is widely adopted due to its chemical resistance, low extractables, and mechanical reliability. In chemical processing, water treatment, and general manufacturing, polypropylene maintains stable performance when exposed to acids, alkalis, and a broad range of process fluids. This makes it a practical material choice for continuous-duty filtration systems.

An industrial liquid filter bag polypropylene construction also supports consistent dimensional stability during operation. Proper fit within the housing reduces the risk of bypass and ensures that all liquid passes through the filtration media as designed. For an Industrial PP Liquid Filter Bag, material consistency across production batches is essential to maintaining predictable filtration behavior over time.

Welded and Sewn Construction Options

Construction method plays a critical role in filtration integrity. A welded PP liquid filter bag is produced through thermal bonding, eliminating needle holes and creating uniform seams. This design is often preferred in processes where cleanliness, leakage prevention, and consistent pressure performance are priorities.

A sewn PP liquid filter bag, on the other hand, is manufactured using industrial stitching techniques. Sewn bags are widely used in general industrial applications and offer flexibility across a range of sizes and micron ratings. When produced under controlled sewing standards, they provide reliable performance in systems with moderate pressure and filtration requirements.

Choosing between welded and sewn designs depends on process sensitivity, operating pressure, and maintenance expectations. Both options are available for Industrial PP Liquid Filter Bag applications, allowing users to balance performance requirements with operational preferences.

Ring Types and Housing Compatibility

Sealing is a critical factor in selecting a PP Liquid Filter Bag. A PP liquid filter bag with plastic ring is commonly used in water treatment and chemical applications where corrosion resistance and lightweight handling are important. Plastic rings provide consistent sealing in standard housings while simplifying installation and removal.

In more demanding environments, a PP liquid filter bag with steel ring offers enhanced mechanical strength and durability. Steel rings are often specified for higher-pressure systems or installations that require frequent bag changes, where dimensional stability is essential to maintaining a secure seal.

Matching ring type to housing design ensures proper fit and minimizes bypass risk. Consistent sealing performance supports accurate filtration results and reduces variability across replacement cycles.

Replacement Planning and Supply Consistency

Effective PP liquid filter bag replacement planning is essential for maintaining system performance and avoiding unplanned downtime. Replacement intervals should be based on differential pressure trends and process conditions rather than fixed schedules alone. Consistent bag construction and material quality help ensure that each replacement performs similarly to the previous one.

Working with a reliable PP liquid filter bag supplier supports this consistency. A dependable supplier provides uniform dimensions, controlled manufacturing processes, and traceable materials, reducing the risk of performance variation. This consistency is especially important for facilities managing multiple filtration points or standardized systems.

From a procurement perspective, selecting a capable PP Liquid Filter Bag Manufacturer simplifies long-term inventory management. Manufacturers that offer welded and sewn options, multiple ring types, and consistent quality enable users to standardize filtration solutions while adapting to different process needs.

Selection Guidance for Process Optimization

Choosing the right PP Liquid Filter Bag involves aligning material, construction, and sealing features with real operating conditions. Evaluating fluid chemistry, operating pressure, temperature, and maintenance practices helps determine whether a welded or sewn design is more appropriate and which ring type best supports housing compatibility.

An Industrial PP Liquid Filter Bag that is correctly specified contributes to stable filtration performance, reduced maintenance effort, and predictable operating costs. By focusing on construction quality and supplier reliability rather than isolated specifications, operators can build filtration systems that perform consistently throughout their service life.