316L Stainless Steel Bag Filter Housing for Reliable Industrial Filtration

In many industrial filtration systems, reliability, material compatibility, and long-term durability are not optional requirements. They are fundamental. A 316L Stainless Steel Bag Filter Housing is designed to meet these expectations in demanding liquid filtration environments where corrosion resistance, hygiene, and stable performance are critical.

As a core type of Bag Filter Housing, this solution is widely used across chemical processing, water treatment, food and beverage production, pharmaceuticals, and other industrial sectors that require consistent filtration with minimal downtime.

What Is a 316L Stainless Steel Bag Filter Housing

A 316L Stainless Steel Bag Filter Housing is a pressure vessel designed to hold one or more liquid filter bags. The housing directs liquid flow through the filter bag, allowing contaminants to be captured while clean liquid exits the system. Compared with carbon steel or plastic housings, 316L stainless steel offers superior corrosion resistance and chemical compatibility.

The low-carbon content of 316L stainless steel reduces the risk of carbide precipitation during welding, making the housing more resistant to intergranular corrosion. This characteristic is especially important in applications involving aggressive chemicals, high temperatures, or frequent cleaning cycles.

As an industrial Bag Filter Housing, it is typically used for medium to high flow rates and can handle a wide range of particle sizes depending on the selected filter bag.

Why Choose 316L Stainless Steel Material

Material selection is one of the most important decisions in filtration system design. A 316L Stainless Steel Bag Filter Housing offers several advantages that make it suitable for harsh and regulated environments.

First, 316L stainless steel provides excellent resistance to acids, chlorides, and saline solutions. This makes the housing ideal for chemical processing, seawater-related applications, and wastewater treatment systems where corrosion can shorten equipment lifespan.

Second, the smooth surface finish of stainless steel helps reduce contaminant buildup and simplifies cleaning. In hygienic processes such as food, beverage, and pharmaceutical production, this is a major advantage.

Third, 316L stainless steel maintains mechanical strength under pressure and temperature variations. As a result, a 316L Stainless Steel Bag Filter Housing delivers stable performance even in continuous industrial operation.

Typical Structure and Design Features

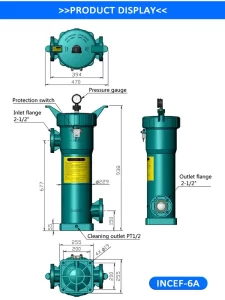

A standard 316L Stainless Steel Bag Filter Housing consists of several key components: the housing body, lid or cover, filter bag basket, sealing gasket, and inlet and outlet connections. The design ensures that liquid flows evenly through the filter bag without bypass.

Most industrial designs support size 1 or size 2 filter bags, allowing flexibility in flow rate and dirt-holding capacity. Single-bag and multi-bag configurations are both available, depending on system requirements.

Sealing is another critical aspect. High-quality gaskets ensure leak-free operation, even under pressure. This is particularly important for chemical or hazardous liquid filtration where leakage is unacceptable.

As a robust Bag Filter Housing, the unit is engineered for easy opening and quick filter bag replacement, helping reduce maintenance time and operational costs.

Industrial Applications

A 316L Stainless Steel Bag Filter Housing is suitable for a wide range of industrial liquid filtration applications.

In chemical manufacturing, it is commonly used to remove solid impurities from acids, solvents, and process liquids. The corrosion resistance of 316L stainless steel ensures long service life even when exposed to aggressive media.

In water treatment systems, this type of Bag Filter Housing is often installed as a pre-filtration or polishing stage. It helps protect downstream equipment such as pumps, membranes, and heat exchangers.

Food and beverage producers rely on 316L Stainless Steel Bag Filter Housing units for filtering syrups, beverages, edible oils, and process water. The material meets hygienic standards and supports frequent cleaning and sanitization.

In pharmaceutical and fine chemical industries, filtration systems must meet strict quality and cleanliness requirements. The smooth finish and chemical stability of 316L stainless steel make it a trusted choice.

Flow Capacity and Filtration Efficiency

One of the key advantages of a 316L Stainless Steel Bag Filter Housing is its ability to handle high flow rates while maintaining efficient particle removal. Bag filters offer a large filtration area, which allows high throughput with relatively low pressure drop.

By selecting the appropriate filter bag material and micron rating, users can tailor the filtration performance to their specific process needs. This flexibility makes the Bag Filter Housing suitable for both coarse and fine filtration tasks.

For applications where flow rate is critical, multi-bag housings can be used to increase capacity without compromising filtration efficiency. This modular approach supports system scalability as production demands grow.

Ease of Maintenance and Operation

Industrial filtration systems must be easy to maintain to minimize downtime. A 316L Stainless Steel Bag Filter Housing is designed with this in mind.

The housing cover can be quickly opened, allowing operators to remove and replace the filter bag with minimal effort. Internal baskets support the bag and prevent collapse during operation, ensuring consistent filtration performance.

Because stainless steel surfaces are easy to clean, routine maintenance is straightforward. This is particularly beneficial in applications where frequent changeovers or cleaning-in-place procedures are required.

As a long-term Bag Filter Housing solution, reduced maintenance time directly translates into lower operating costs and improved process efficiency.

Compatibility with Different Filter Bags

Another important advantage of a 316L Stainless Steel Bag Filter Housing is its compatibility with a wide range of filter bag materials. Depending on the application, bags can be made from polypropylene, polyester, nylon, or other specialty materials.

This flexibility allows users to address different filtration challenges using the same housing. Whether the goal is particle removal, gel filtration, or sludge separation, the Bag Filter Housing can be adapted by simply changing the filter bag.

The ability to switch filter bags without modifying the housing makes system optimization faster and more cost-effective.

Pressure Rating and Safety

Safety is a critical consideration in industrial filtration. A 316L Stainless Steel Bag Filter Housing is designed to operate safely under specified pressure limits. The robust construction ensures structural integrity even in demanding conditions.

Proper sealing and secure lid locking mechanisms help prevent leaks or accidental opening during operation. This level of safety is essential when filtering hazardous or high-temperature liquids.

When correctly specified and installed, a 316L Stainless Steel Bag Filter Housing provides reliable, safe operation across a wide range of industrial processes.

Long-Term Value and Cost Efficiency

Although stainless steel housings typically have a higher initial cost than plastic alternatives, the long-term value of a 316L Stainless Steel Bag Filter Housing is significant.

Its resistance to corrosion, mechanical wear, and chemical attack reduces the need for frequent replacement. Over time, this durability results in lower total ownership cost.

In addition, the consistent performance of a high-quality Bag Filter Housing helps protect downstream equipment, reducing maintenance and replacement expenses elsewhere in the system.

Choosing the Right Bag Filter Housing

Selecting the right 316L Stainless Steel Bag Filter Housing involves considering flow rate, operating pressure, liquid type, temperature, and required filtration level. Working with an experienced manufacturer or supplier can help ensure the housing is correctly matched to the application.

A well-designed housing not only improves filtration performance but also simplifies operation and maintenance over the life of the system.

Conclusion

A 316L Stainless Steel Bag Filter Housing is a dependable solution for industrial liquid filtration where durability, chemical resistance, and hygienic design are essential. As a versatile Bag Filter Housing, it supports a wide range of applications while delivering stable performance and long service life.

For industries seeking a filtration system that balances efficiency, safety, and long-term value, a 316L stainless steel bag filter housing remains a proven and trusted choice.